Product testing Product testing is a key link to ensure...

Electrode material preparation

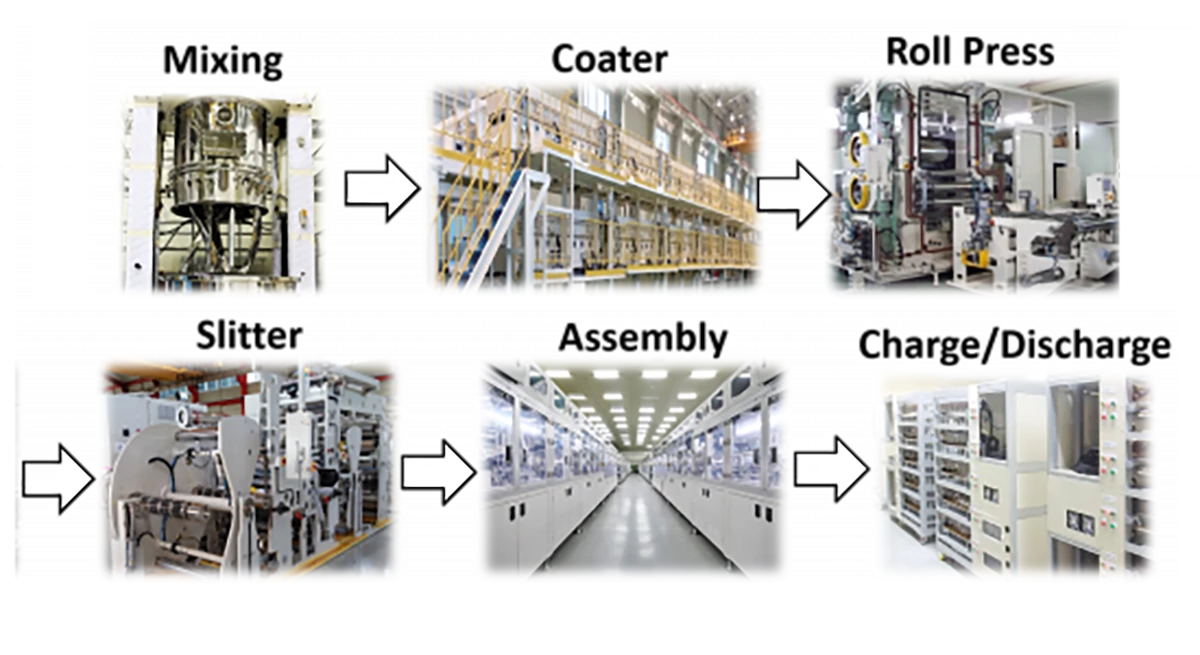

Electrode material preparation is a key step in lithium battery manufacturing, including the selection of anode and cathode materials, slurry preparation, coating, drying and calendering processes. First, appropriate positive and negative active materials (such as ternary materials, lithium iron phosphate, graphite, etc.) are selected and mixed with conductive agents and adhesives to make a slurry. Then, the slurry is evenly coated on the collector fluid, and the solvent is removed by drying to ensure that the electrode is stable. Finally, after calendering and cutting, the appropriate size of the electrode sheet is obtained, which provides guarantee for the assembly and performance of the battery.

Electrode material preparation

By precisely controlling these process steps, the uniformity, stability and high performance of the electrode material are ensured, thus laying the foundation for the energy density and cycle life of the battery.

Detailed procedure

Positive electrode material is a key component of lithium batteries, and common positive electrode materials are ternary materials (lithium nickel-cobalt manganate, NCM) and lithium iron phosphate (LFP). Ternary materials have a higher energy density, while lithium iron phosphate has better thermal stability and a longer service life. The cathode material is usually formed into nanoparticles through chemical synthesis, ball milling and other processes, and is mixed with conductive agents and adhesives in the subsequent slurry preparation.

The preparation of cathode materials determines the energy output and service life of the battery, and the selection and treatment of different materials directly affect the battery performance.

The anode material is usually graphite or silicon matrix composite material. Graphite materials have better stability and cycle performance, while silicon-based materials have higher theoretical capacity, which can improve the energy density of the battery. The preparation process of the anode material includes high temperature heat treatment and ball milling to improve its purity and electrochemical activity.

The quality of the anode material determines the charge and discharge efficiency and cycle life of the battery, and the selection and treatment process of the material are crucial to the performance of the battery.

Electrolyte is the medium of charge transfer in lithium batteries, usually made from lithium salts (such as LiPF6) dissolved in organic solvents (such as carbonate esters). The composition and concentration of the electrolyte directly affect the conductivity, stability and safety of the battery. The separator is the barrier between the positive and negative electrodes in the battery, and the commonly used material is polyethylene (PE) or polypropylene (PP), whose main role is to prevent short circuit and allow lithium ions to pass through.

The preparation of electrolyte and diaphragm ensures the ionic conductivity and safety of the battery, and good electrolyte formula and high-quality diaphragm can effectively improve the performance and service life of the battery.

low-speed car batteries

Low-speed vehicle battery is a kind of battery designed for low-speed electric vehicles, which has the characteristics of clean, environmental protection, high efficiency and economy, and is widely used in electric golf carts, low-speed electric vehicles (LSV), mobile vendors, campus transportation, cargo trucks and so on

Extended reading

Product packaging and delivery

Product packaging and delivery The packaging and delivery of battery...

Product information expansion

Product information expansion Understanding low-speed vehicle battery product information is...

Product composition

Low-speed lithium battery product composition Understanding the product composition of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.