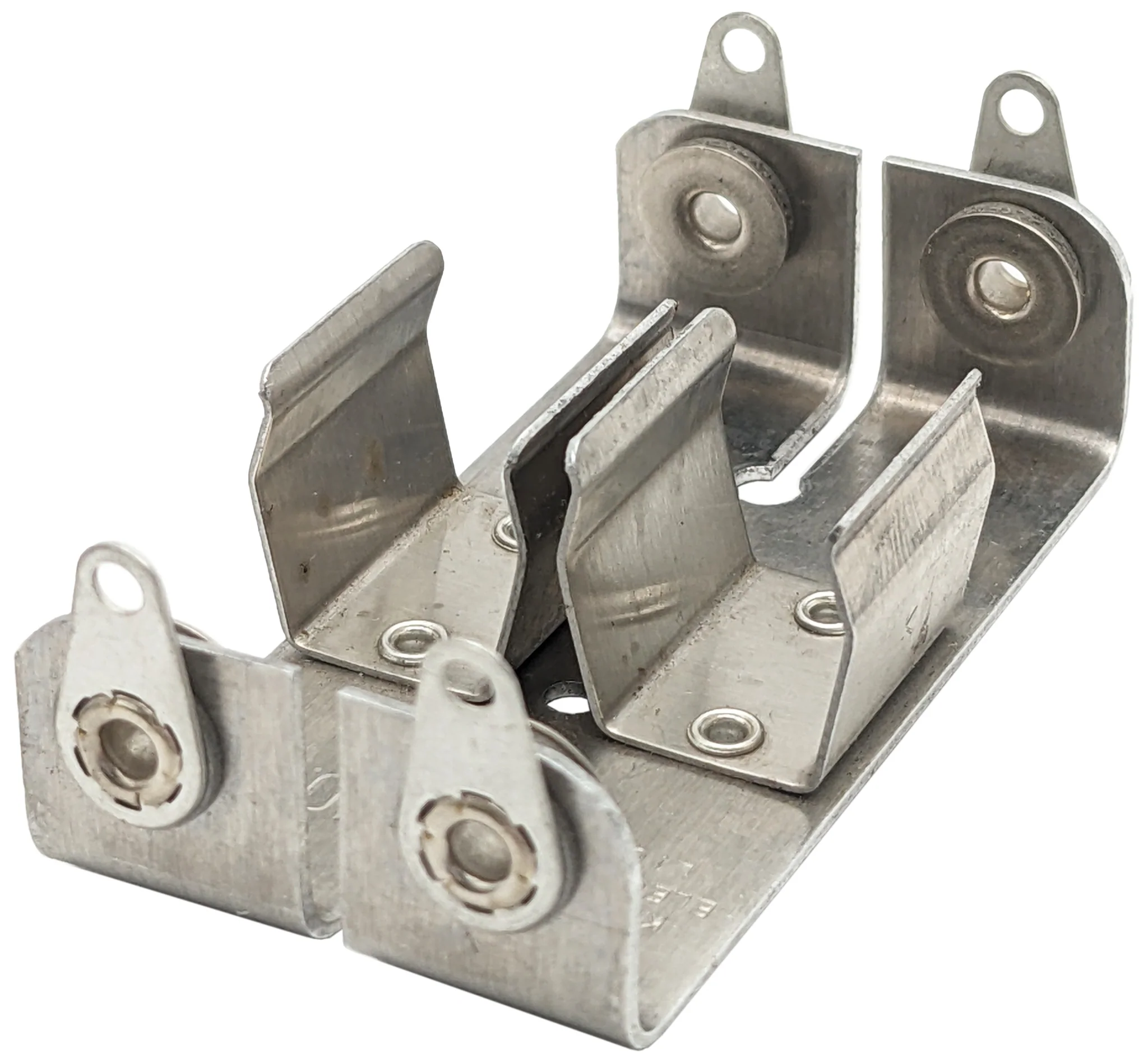

The socket terminal of the battery pack The role of...

Wet mixing technology of electrode

Wet mixing technology is an important part of the preparation of lithium ion battery electrode, and its process is directly related to the performance of the electrode and the overall performance of the battery. This paper will focus on the wet mixing process of electrodes, including the formation of sol, mixing of conductive agents, mixing of active substances and dilution of basic processes.

Overview of wet mixing process

Wet mixing is a method of combining solid materials with liquids in order to improve the dispersion and uniformity of materials. In the preparation of electrode materials, wet mixing can ensure adequate mixing of active materials, conductive agents and binders, thereby improving the electrical conductivity and mechanical strength of electrodes. The core of the process lies in the efficient mixing of materials through a liquid medium.

The basic process of electrode wet mixing

To form a sol

In the first step of wet mixing, a suitable solvent (such as N-methyl pyrrolidone, NMP) is selected to dissolve the binder (such as polyvinylidene fluoride, PVDF) to form a sol. In this process, the choice of solvent is crucial, it should be able to effectively dissolve the binder, while having no adverse effects on other materials. The formed sol creates a good basis for the subsequent mixing process.

Mixed conductive agent

After obtaining the sol, the next step is to mix a conducting agent such as carbon black or conducting polymer. The amount of conductive agent added should be precisely controlled to ensure that it can effectively provide conductive access in the electrode. The mixing process usually uses high shear stirring to ensure uniform dispersion of the conductive agent in the sol, thus improving the overall conductivity of the electrode.

Mixed active substance

After finishing the mixing of the conductive agent, the active substances (such as lithium cobalt oxide, lithium iron phosphate, etc.) are added to the above mixture. This step is a key link in the wet mixing process to ensure that the active substance is evenly mixed with the conductive agent and the binder. Usually, the equipment used includes a planetary mixer or a high shear mixer to ensure that the material is fully dispersed during the mixing process.

Dilution

According to the viscosity of the mixture and the requirements of the subsequent coating, the final step is to dilute the mixture. This step is usually done by adding an appropriate amount of solvent to adjust the fluidity and adjustability of the finished slurry. The diluted slurry should ensure consistency and appropriate viscosity, so that the subsequent coating operation can be carried out smoothly.

the advantages of wet mixing process

The wet mixing process of electrodes has the following significant advantages:

High uniformity: Wet mixing can effectively eliminate the differences between components and improve the uniformity of the slurry, thereby optimizing the performance of the electrode.

Adjustability: In the process, the parameters of each step (such as stirring speed, time and infiltration time) can be adjusted to meet the needs of different electrode materials.

Good bonding: through the liquid phase medium, the binder can be more effectively combined with the active substance, improving the overall strength of the electrode.

Increased electrical conductivity: With appropriate mixing of conductive agents, the wet mixing process can significantly improve the electrical conductivity of the electrode and improve the discharge performance.

conclusion

The wet mixing process of electrodes is an important technology to achieve high performance battery manufacturing. Through the steps of sol formation, mixed conductive agent, mixed active substance and dilution, the uniformity and performance of electrode materials are effectively improved, which provides strong support for the wide application of lithium-ion batteries. With the continuous progress of battery technology, the wet mixing process will continue to play an important role in contributing to the innovation and development of the battery industry. Through the continuous research and optimization of wet mixing process, we believe that we will be able to produce more efficient and safer battery products in the future.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

How to test the static voltage of a single battery

How to test the static voltage of a single battery...

Introduction to the guide parts of battery pack

Introduction to the guide parts of battery pack In the...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.