Product testing Product testing is a key link to ensure...

The exploration of new materials

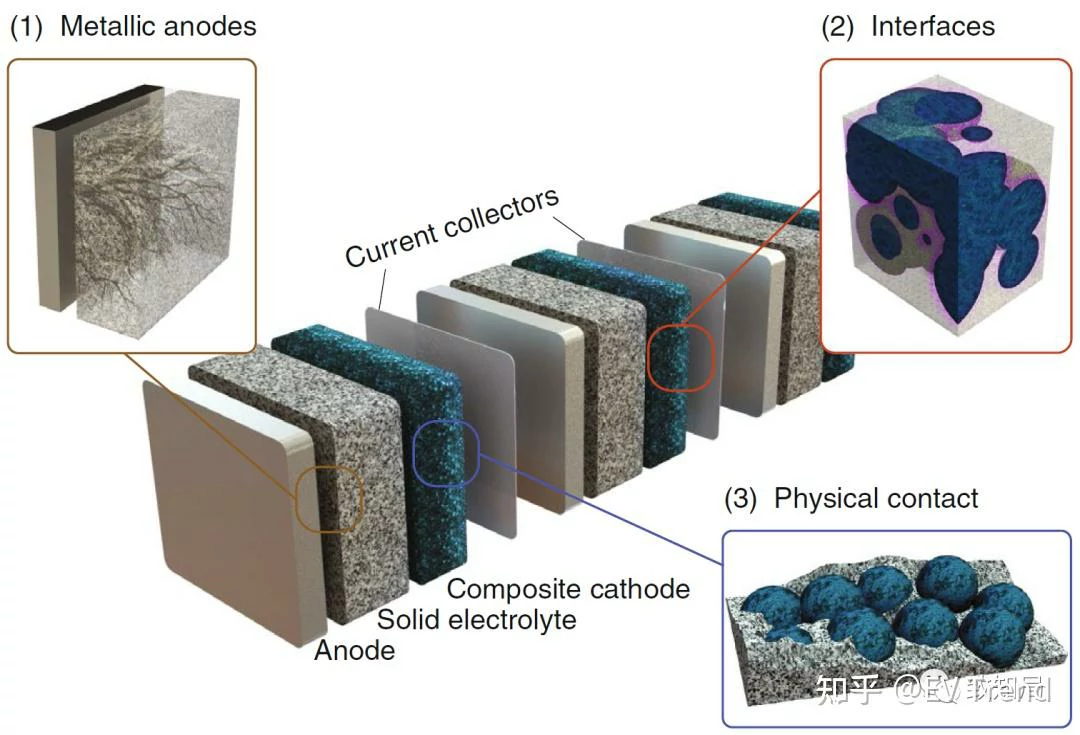

When the liquid electrolyte used in traditional lithium-ion batteries is combined with higher performance positive and negative electrode materials (such as pure lithium metal negative electrode), it is easy to form lithium dendrites, resulting in accidental short circuit, causing thermal runaway or even spontaneous combustion explosion, so the solid electrolyte with high thermal stability can be compatible with high pressure positive electrode materials and inhibit the growth of lithium dendrites to match the high capacity lithium metal negative electrode.

Product goals and upgrade directions

The current mainstream solid electrolyte technology route can be divided into polymer, oxide and sulfide according to the electrolyte material system. The semi-solid transition system composed of liquid electrolyte, polymer and oxide composite solid electrolyte has a rapid commercialization progress, but the high-performance positive and negative electrode carrying capacity is limited, and it is mainly used in high-security application scenarios. Oxide and sulfide all-solid electrolytes are commonly sought as the final solution for solid electrolytes.

Classification of solid electrolytes

Polymer electrolyte

Good flexibility and easy processing, similar to the existing lithium battery preparation method, high process compatibility, can achieve large-scale mass production, is the first commercial application of solid electrolyte. However, the ionic conductivity at room temperature is low, and the conductivity can be increased to 10-3 S/cm when heated to a high temperature of 60 ° C, and the low mechanical strength has poor inhibition effect on lithium dendrites and narrow electrochemical window, which also weakens the advantages of high energy density of solid-state batteries. Therefore, the simple polymer electrolyte route has been basically eliminated, and it is currently mixed with oxide solid electrolyte for semi-solid batteries.

Oxide electrolyte

Good thermal stability, room temperature ionic conductivity up to 10-5~10-4S/cm, doping modification can be increased to 10-3S/cm, high electrochemical window can match high pressure cathode materials. However, the oxide electrolyte has high mechanical strength, poor contact with the electrode material, and high porosity, resulting in excessive interface impedance, and the texture is brittle and difficult to process. Due to the good comprehensive performance of oxide solid electrolyte and the difficulty of preparation, it is the fastest growing solid electrolyte route, Europe, the United States and China have been laid out, and domestic enterprises are promoting the solid-liquid hybrid battery products based on oxide solid electrolyte, which is expected to take the lead in mass production within three years.

Sulfide electrolyte

Ionic conductivity of up to 10-3~10-2S/cm, comparable to liquid electrolyte, while with good mechanical strength and flexibility, good interface contact. However, it has strong chemical activity, poor compatibility with high-pressure cathode materials and lithium metal negative electrodes, and it is easy to react with water in the air to produce highly toxic gas hydrogen sulfide. In summary, sulfide electrolyte is the most potential development route, China, the United States, Japan and South Korea have layout, but many technical difficulties still need 5-7 years to break through.

low-speed car batteries

Low-speed vehicle battery is a kind of battery designed for low-speed electric vehicles, which has the characteristics of clean, environmental protection, high efficiency and economy, and is widely used in electric golf carts, low-speed electric vehicles (LSV), mobile vendors, campus transportation, cargo trucks and so on

Extended reading

Product packaging and delivery

Product packaging and delivery The packaging and delivery of battery...

Product information expansion

Product information expansion Understanding low-speed vehicle battery product information is...

Product composition

Low-speed lithium battery product composition Understanding the product composition of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.