Study on mechanical protection material of positive cap In modern...

Wet coating

Wet coating is a key industrial technology that is widely used in coating manufacturing, printed circuit boards, battery electrode production, and thin film material preparation. The process involves evenly coating a liquid material on a substrate and subsequently forming a uniform coating by drying or curing. This method is noted for its ease of operation, low cost, and applicability to a variety of materials.

The principle of wet coating

The core of wet coating is to apply liquid substances such as solution, suspension or emulsion to the surface of the substrate through specific coating equipment. Then, the coating is cured into a final state through steps such as evaporation, heat treatment or chemical reactions. Controlling the viscosity of the coating solution, coating thickness and drying conditions is the key to ensure the quality of the final coating.

The materials of the coating link

Coating particles (coating materials) : can be divided into two categories: inorganic and organic. Inorganic materials mainly include ceramics (Boehm stone, alumina), organic materials mainly include PVDF, PMMA, aramid, etc. The main advantage of inorganic materials is that the technology is more mature, the production cost is lower, the cost performance is high, and the economy has obvious advantages compared with organic coating; The biggest advantage of organic coating is that the product performance is good, but the price is expensive.

Coating solvent: can be divided into oil (acetone, NMP, etc.) and water (deionized water, ethanol, glycerin, etc.) two kinds. Oily coating is used for organic coating particles, and its uniformity and adhesion are better than water-based coating, but the cost is high, and it is mainly used for high-end batteries. Although water-based coating has some deficiencies in performance, it has high cost performance.

Application field of wet coating

Battery manufacturing

In lithium-ion batteries, wet coating is used to evenly coat the active material paste on the electrode collector to ensure good performance and consistency of the electrode.

Electronic manufacturing

In the production of printed circuit boards, wet coating is used to coat solder mask and conductive materials to form fine circuit patterns.

Coating industry

Used to manufacture surface coatings for a variety of purposes, including anti-corrosion, waterproof and aesthetic decoration. Widely used in metal, plastic and wood substrate surface treatment.

Thin film preparation

In thin film manufacturing of optical, electronic and packaging materials, wet coating techniques are used to produce thin films with specific optical and physical properties.

Advantages and disadvantages of wet coating

Advantages

Simple operation: The coating process is simple and easy to operate, suitable for mass production.

Material diversity: A variety of chemical components and their combinations can be used to meet different application requirements.

Cost effective: Compared to some other more complex coating methods, wet coating equipment and process costs are lower.

Good uniformity: It can achieve uniform and consistent coating quality over a large area.

Disadvantages

Solvent treatment: When using coating materials containing solvents, volatile organic compounds need to be controlled and treated, especially in areas with strict environmental requirements.

Equipment corrosion: Certain chemical components may cause corrosion to the coating equipment, requiring special material protection and equipment maintenance.

Drying step: The drying process after coating may affect production efficiency and energy consumption and needs to be precisely regulated.

Technical development of wet coating

With the development of technology, wet coating is constantly evolving. New technologies are increasing coating efficiency, improving material properties and reducing environmental impact. For example, the application of nanotechnology is improving the functionality and durability of coatings. In addition, advanced drying technology and equipment will further optimize the entire coating process, improve production speed and product consistency.

conclusion

As a mature and diversified surface treatment technology, wet coating has attracted much attention in industry because of its wide range of applications and technical advantages. Despite challenges such as environmental protection and equipment maintenance, continuous technological innovation and improvement are continuously expanding their application prospects and capabilities. In the future, with the improvement of material performance requirements and strict environmental protection standards, wet coating will continue to play an important role in industrial production.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

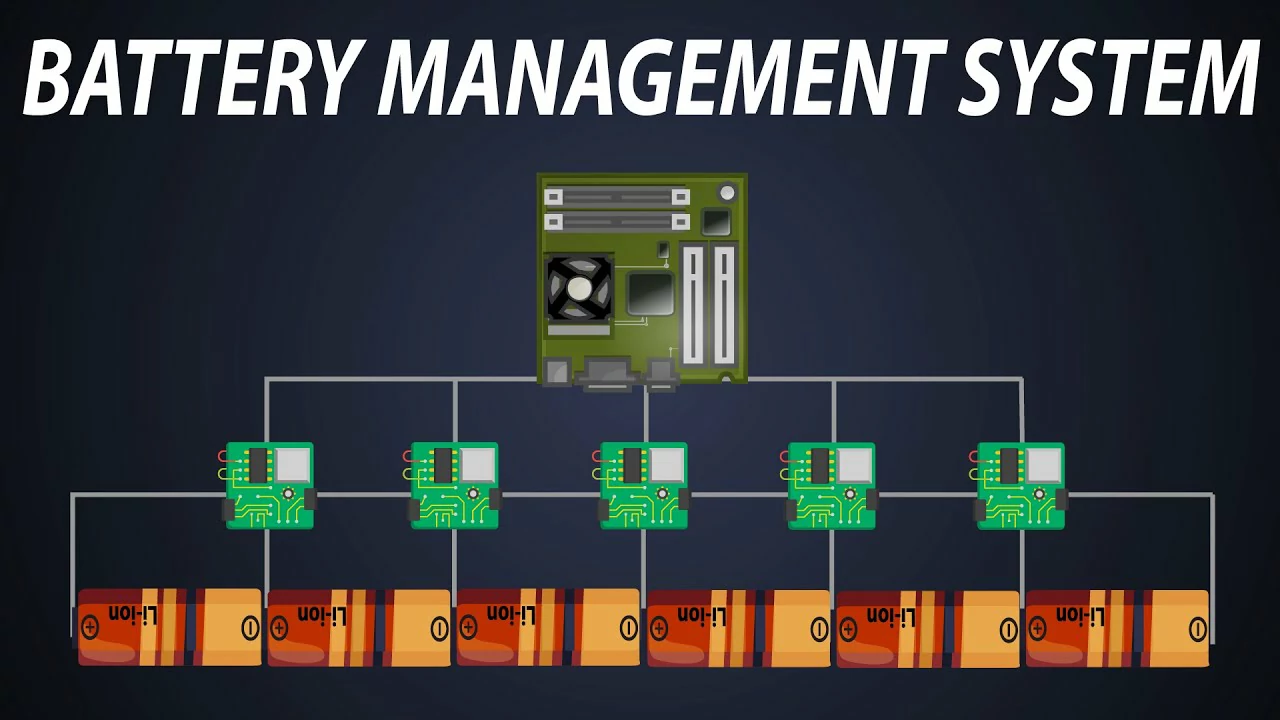

Distributed Battery Management System (BMS)

Distributed Battery Management System (BMS) With the widespread use of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.