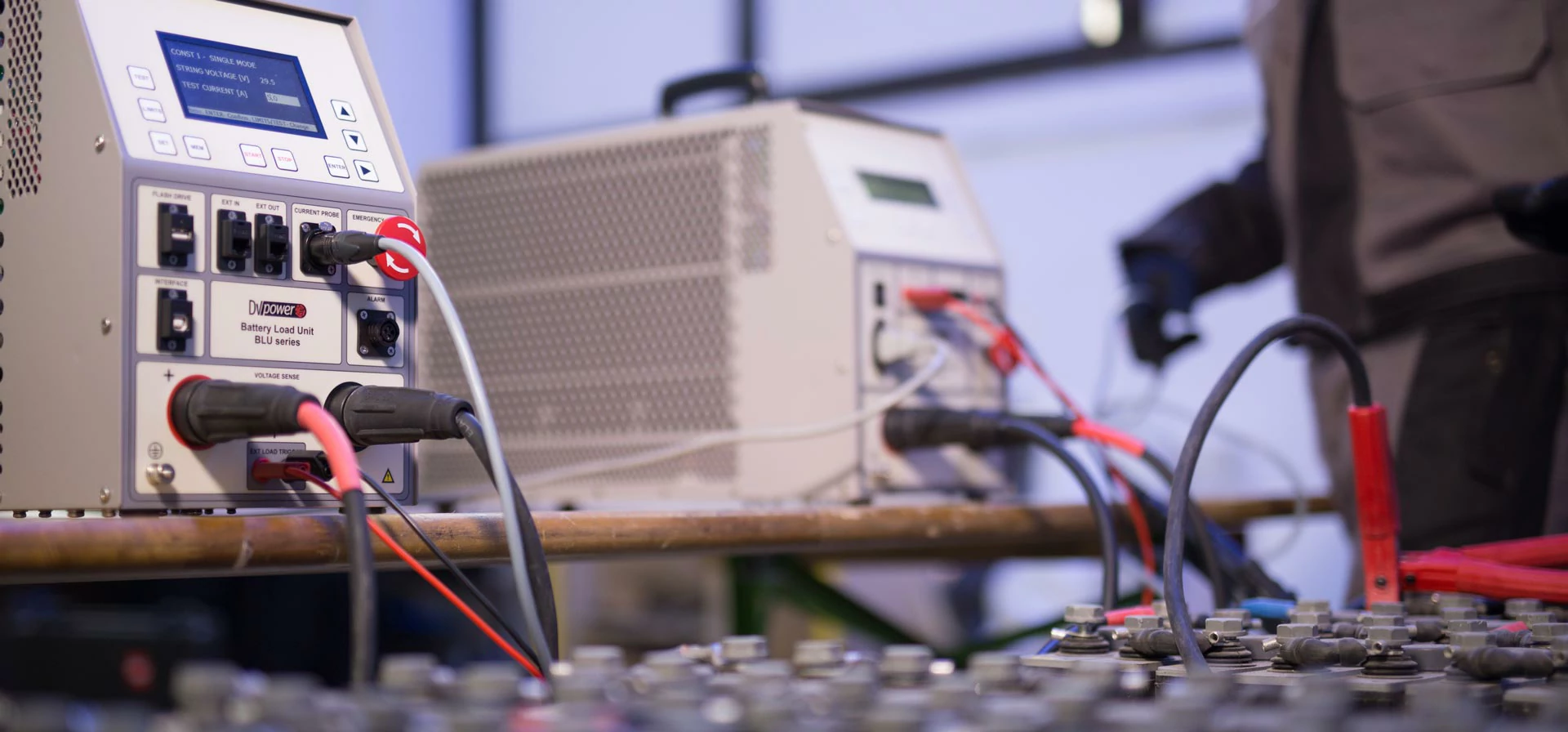

Capacity testing of single cell batteries As the most basic...

Dry single pull process

Dry single drawing process is the use of good mobility, low molecular weight polyethylene (PE) or polypropylene (PP) polymer, using the manufacturing principle of hard elastic fiber, the first preparation of high orientation, low crystallization of polyolene casting, low temperature stretching to form silver grain and other micro-defects, the use of high temperature annealing to make the defects open, and then obtain uniform pore size, uniaxial orientation of the microporous film.

The process flow of dry single drawing

1) Feeding: the raw materials such as PE or PP and additives are pretreated according to the formula and transported to the extrusion system.

2) Flow casting: the pretreated raw material is extruded from the die head after melt plasticization in the extrusion system, and the melt is formed into a specific crystalline structure of the base film after flow casting.

3) Heat treatment: the base film is heat treated to obtain a hard elastic film.

4) Stretching: the hard elastic film is cold-stretched and hot-stretched to form a nano-microporous film.

5) Cutting: cutting the nanoporous membrane into finished film according to the customer's specifications.

Characteristics of dry single drawing process

The mechanical properties of materials are improved

Through unidirectional stretching, the molecular chains of the material tend to be aligned, so that the tensile strength, tear strength and compressive strength of the film are significantly improved. Compared with unstretched films, dry single-pull films usually have better heating shrinkage and puncture resistance.

Pore structure optimization

In the process of dry single drawing, the microscopic pore structure of the material will change, forming uniform and moderate pores, which is crucial for applications such as lithium battery separator. This pore structure can not only improve ionic conductivity, but also ensure good electrolyte infiltrability.

Thermal and dimensional stability

After heat shaping, the film can maintain a relatively stable size under higher temperature conditions, reducing the risk of deformation caused by temperature changes in practical applications.

High production efficiency

The dry single drawing process is relatively simple, easy to scale production, and can meet the needs of large-scale industrial production.

Application of dry single drawing process

Lithium battery separator

The polymer thin film prepared by dry method is widely used in lithium battery separator, which has excellent electrical insulation and ionic conductivity.

Packaging materials

Dry single-pull film is widely used in food, medicine and other packaging fields, its excellent strength and air permeability effectively extend the fresh-keeping period of products.

Optical films

Thin films used to manufacture various optical devices. The dry single-pull process can optimize the optical properties of thin films to meet the needs of different applications.

Electronic products

Electronic products In electronic components, such as conductive film, insulating film can be used to improve the performance of materials by dry single pull process.

conclusion

As an efficient and environmentally friendly film manufacturing technology, the dry single drawing process is gaining more and more attention in various industries by virtue of its superior performance and wide application prospects. With the development of material science and manufacturing technology, the dry single drawing process will play a more important role in the future advanced material manufacturing.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

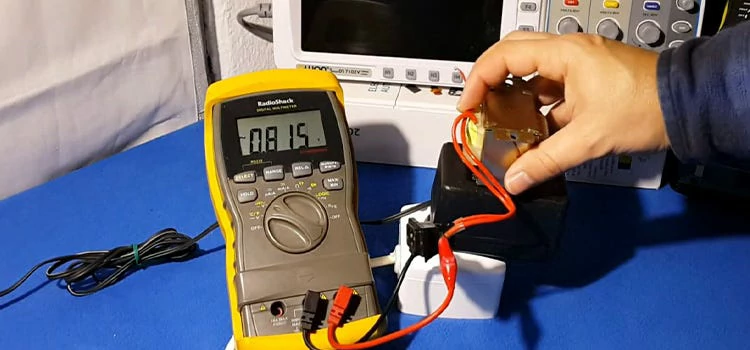

How to test the voltage drop of a single battery

How to test the voltage drop of a single battery...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.