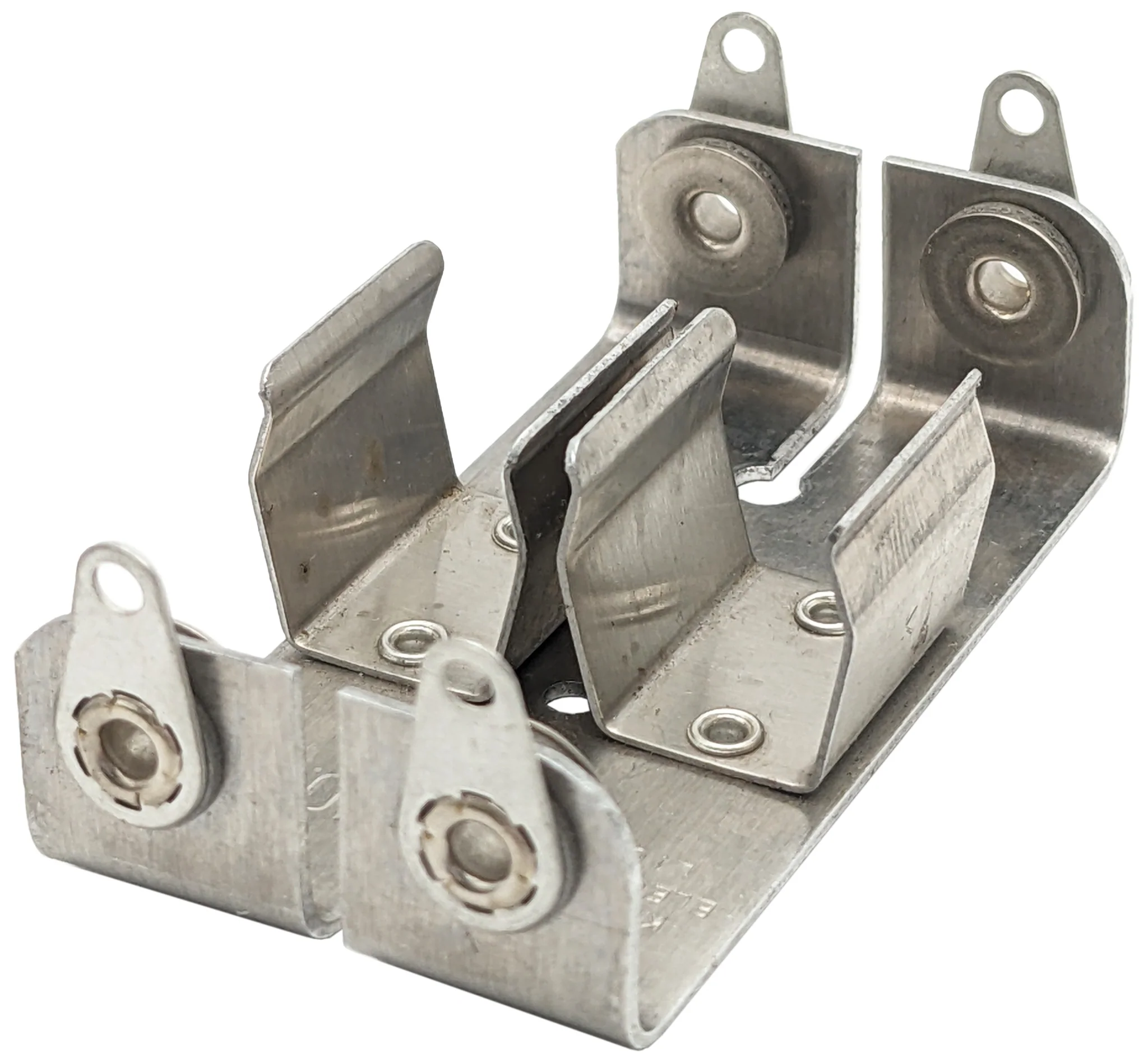

Battery pack support In battery energy storage and electric vehicle...

Manufacturing process of lithium battery diaphragm

The lithium battery separator is mainly prepared by two different processes: dry and wet. According to the different technical routes, lithium battery separator can be divided into dry unidirectional stretch process separator, dry bidirectional stretch process separator, wet process separator.

dry process

The dry diaphragm process is the most commonly used method in the preparation of the diaphragm. The process is to mix polymers, additives and other raw materials to form a uniform melt, form a wafer structure under tensile stress during extrusion, heat treatment of the wafer structure to obtain a hard elastic polymer film, and then stretch at a certain temperature to form slit micropores, and heat setting to produce microporous film. At present, the dry process mainly includes two kinds of dry unidirectional stretching and bidirectional stretching.

Dry double pulling process is a process developed by the Institute of Chemistry, Chinese Academy of Sciences with independent intellectual property rights, and is also a unique diaphragm manufacturing process in China. Because the β crystal of PP is a hexagonal crystal system, single crystal nucleation and loose wafer arrangement, it has a radial growth into a dispersive bundle of wafer structure and does not have a complete spherical crystal structure. Under the action of heat and stress, it will transform into a more compact and stable α crystal, and will produce holes in the material after absorbing a large amount of impact energy. In this process, β crystal modifier with nucleation effect was added to PP, and the density difference between different phases of PP was used to generate crystal transformation to form micropores during the stretching process.

Dry single drawing process is the use of good mobility, low molecular weight polyethylene (PE) or polypropylene (PP) polymer, using the manufacturing principle of hard elastic fiber, first prepared high orientation, low crystallization of polyolefin casting, low temperature stretching to form silver grain and other micro-defects, the use of high temperature annealing to make the defect pull apart. Furthermore, the microporous films with uniform pore size and uniaxial orientation were obtained.

Wet process is also known as phase separation method or heat-induced phase separation method, liquid hydrocarbon or some small molecular substances and polyolene grease mixed, heating and melting, forming a uniform mixture, and then cooling phase separation, pressing the diaphragm, and then heating the diaphragm to close to the melting point temperature, bi-directional stretching to make the molecular chain orientation, and finally holding a certain time, The porous membrane material can be prepared by eluating the residual solvent with volatile substances. According to whether the orientation is at the same time, the wet process can also be divided into wet bidirectional asynchronous stretching process and bidirectional synchronous stretching process.

The overall performance of wet diaphragm is better than that of dry diaphragm. The performance of the diaphragm product is affected by the matrix material and the manufacturing process. The stability, consistency and safety of the diaphragm have a decisive influence on the discharge rate, energy density, cycle life and safety of the lithium battery. Compared with dry diaphragm, wet diaphragm in thickness uniformity, mechanical properties (tensile strength, puncture strength), air permeability, physical and chemical properties (wettability, chemical stability, safety) and other material properties are more excellent, conducive to the electrolyte liquid absorption and retention and improve the battery charging and discharging and cycling capacity, suitable for high-capacity batteries. From the perspective of product force, the comprehensive performance of wet diaphragm is stronger than that of dry diaphragm.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

Valve-controlled relief valves

valve-controlled relief valves In industrial automation and all kinds of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.