PCS routine parameter sorting PCS routine parameter sorting Rated power...

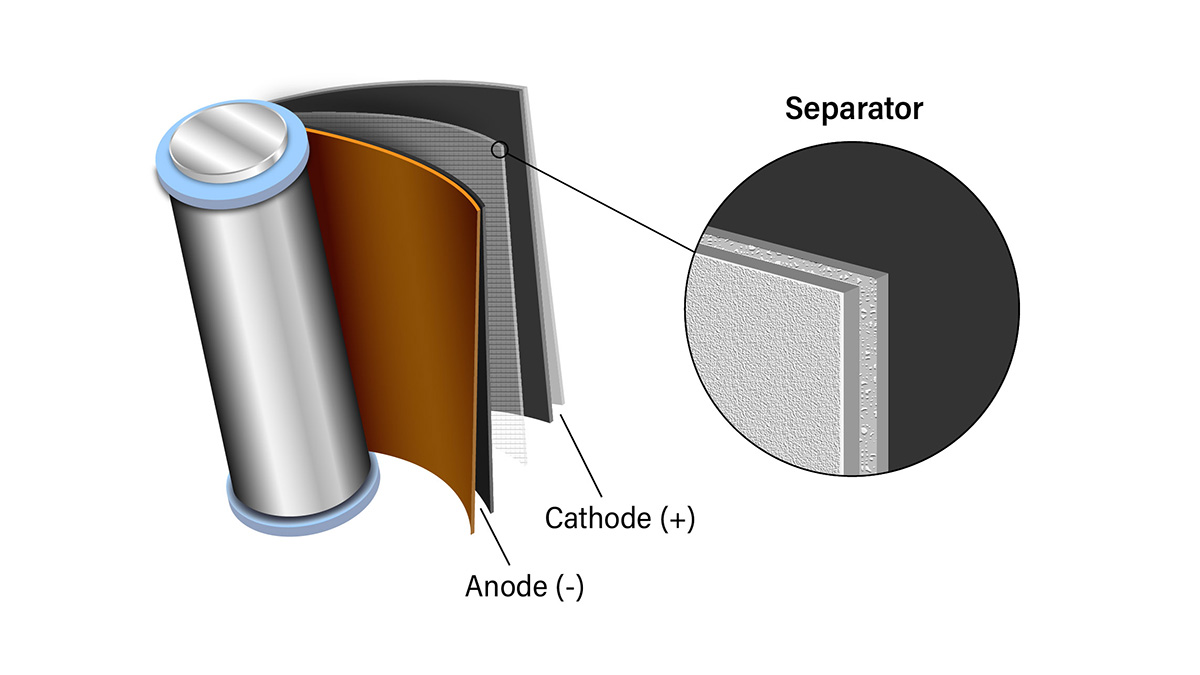

What is lithium battery separator

Li-ion battery separator is an important part of Li-ion battery, located between the positive and negative electrodes, plays the role of electrical insulation, while allowing the free passage of lithium ions during charging and discharging. The existence of the diaphragm helps to prevent the short circuit inside the battery and maintain the safety and stability of the battery. Therefore, the diaphragm is crucial in improving the performance and prolonging the service life of the lithium battery.

The diaphragm is generally composed of microporous films, whose pore structure and thickness directly affect the electrical conductivity and thermal stability of lithium batteries. A good diaphragm should not only have high ionic conductivity, but also sufficient mechanical strength and temperature resistance to cope with the extreme conditions that the battery may encounter during operation.

The manufacturing materials of lithium battery diaphragm mainly include the following categories: polyethylene (PE), polypropylene (PP), silicate materials, coated diaphragm materials, inorganic materials.

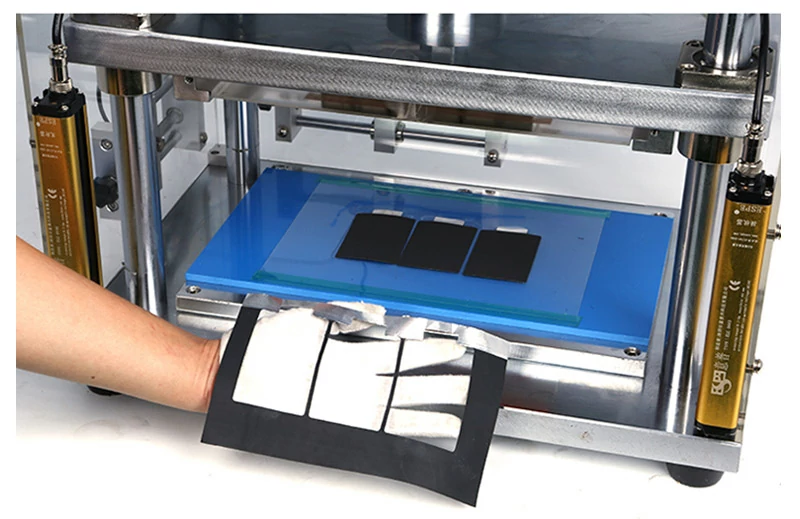

The manufacturing process of lithium battery separator can be mainly divided into dry process and wet process.

Wet process

The wet process is another method for manufacturing lithium battery separators, which usually involves dissolving the polymer in a solvent and then forming a film on the substrate by casting, coating, etc. After the film is formed, the polymer is re-solidified by removing the solvent to form a membrane with a microporous structure. The advantage of the wet process lies in the accurate control of the porosity and microstructure of the diaphragm, which is suitable for the manufacture of high performance diaphragms, but the production cost is relatively high.

Dry process

In the dry process, the polymer material is fused and extruded and stretched to form a microporous structure during a subsequent cooling process. In this process, the polymer shrinks as it cools, creating pores. The advantages of the dry process include the simplicity of the production process, high efficiency, and suitability for large-scale production. But the disadvantage is that the distribution and size of holes may not be precisely controlled.

conclusion

Lithium battery separator is an important guarantee for battery performance and safety, and its design and manufacturing material selection are very important. The analysis of different materials and manufacturing processes can provide theoretical basis and practical guidance for the development and innovation of lithium batteries in the future. With the progress of science and technology, a variety of new materials and processes will continue to emerge in the field of lithium battery separator, promoting the further improvement and wide application of lithium battery technology.

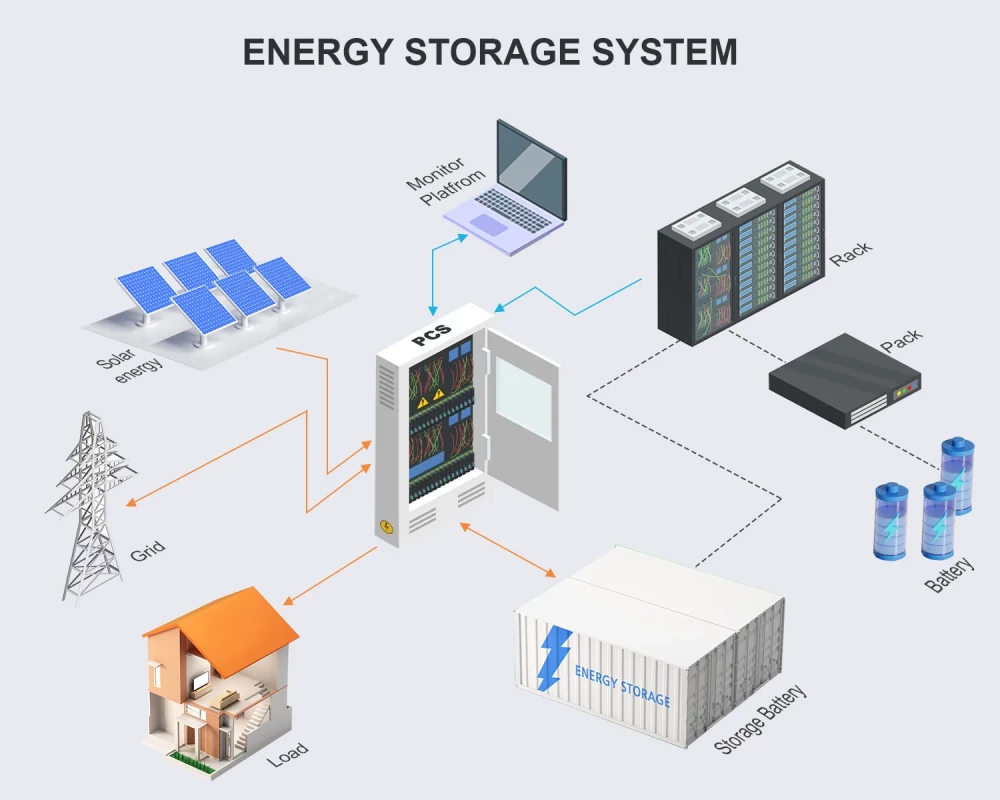

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.