Humidity test of single cell With the continuous pursuit of...

Research on manufacturing material of negative electrode

As an important type of lithium-ion battery, lithium iron phosphate battery has attracted wide attention due to its excellent safety, long cycle life and excellent thermal stability. Its widespread use in electric vehicles, energy storage systems, as well as other applications makes the in-depth study of its components a top priority. As a key component of lithium iron phosphate battery, the manufacturing material of negative electrode not only affects the overall performance of the battery, but also directly relates to the efficiency and reliability of the battery. This paper will introduce the main manufacturing materials and characteristics of the negative electrode sheet.

Graphite material

Natural and artificial graphite

The cathode material of lithium iron phosphate battery is mainly graphite. Natural graphite and artificial graphite are two commonly used forms. Natural graphite has good electrical conductivity and high electrochemical stability, which can effectively support the embedding and deembedding of lithium ions. However, artificial graphite can be designed and optimized more accurately in performance because of its better process control.

Advantages of graphite

The layered structure of graphite enables lithium ions to be effectively embedded and deembedded during charging and discharging, thus achieving high electrical capacity and good cycle stability. This property makes graphite one of the most mature and commonly used choices of anode materials today.

Silicon-based materials

Advantages of Silicon

Silicon is a material with an extremely high theoretical specific capacity, reaching 4200 mAh/g, which is much higher than graphite. This makes it an alternative material that researchers are actively exploring. The use of silicon as the negative electrode material can significantly improve the energy density of the battery.

Commercialization Challenges

Despite the excellent capacity properties of silicon, the volume expansion effect of silicon during charging and discharging may lead to the rupture of the material and affect the service life. To this end, researchers usually use silicon and graphite composite to slow down the expansion effect and maintain the stability of the structure and the reliability of the performance.

The degassing treated electrolyte needs to go through certain filtration steps to remove possible solid impurities and ensure the cleanliness of the electrolyte. Subsequently, the filtered electrolyte is filled into the cell, usually protected with an inert gas to avoid the reaction of the electrolyte with moisture and oxygen in the air.

Composite materials

Combination advantages

In addition to single graphite and silicon materials, composite materials are also an important area in the fabrication of negative electrode sheets. Studies have shown that combining graphite with other conductive materials or oxides can significantly improve the overall performance of batteries. For example, graphite/silicon composites provide high capacity while maintaining structural stability to a certain extent.

Other composite materials

At present, researchers are also trying to use other conductive polymers and functional materials for composite to further optimize the performance of the negative electrode sheet. For example, by adding conductive polymers, the internal resistance of the electrodes can be reduced and the power output capability of the battery can be improved.

Conductive agent and binder

Role of conductive agent

In order to improve the conductivity of the negative electrode sheet, it is usually necessary to add conductive agents to the material, commonly used conductive agents include carbon black, conductive polymers, etc. These conductive agents can effectively reduce the internal resistance of the negative electrode and improve the charging and discharging efficiency of the battery.

Importance of binder

The binder also plays a vital role in the cathode material. Binders such as polyvinylidene fluoride (PVDF) are used to combine active materials, conductive agents, and fluid collectors, thereby improving the structural stability and mechanical strength of the electrode. The choice and dosage of binder directly affect the overall performance of the negative electrode sheet.

Conclusion

From the traditional graphite to the emerging silicon-based materials and various composite materials, the manufacturing materials of the negative electrode of lithium iron phosphate battery are constantly developing and innovating. With further research on new materials, future negative materials are expected to achieve significant improvements in energy density, cycle stability, and overall performance. This will provide strong support for the further development of electric vehicles as well as renewable energy storage technologies. Exploring and optimizing the manufacturing materials of the negative electrode of lithium iron phosphate battery is one of the important directions to promote the progress of battery technology.

Home energy storage product series

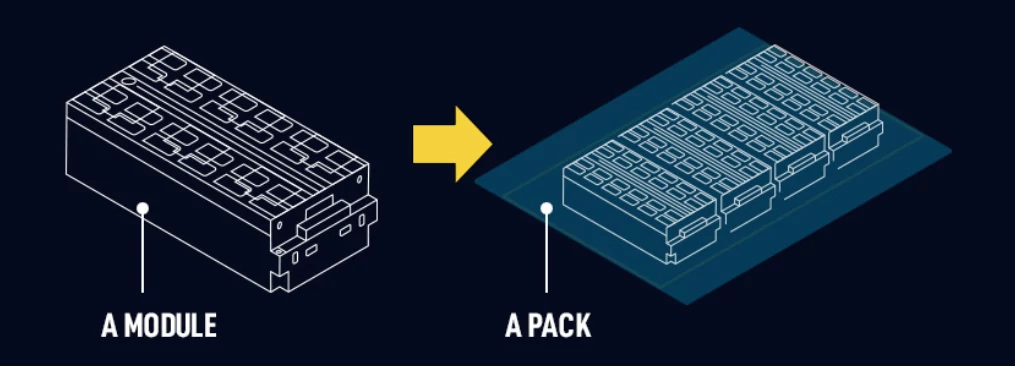

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

Smart home energy storage battery

A highly integrated backup power solution for solar home energy...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.