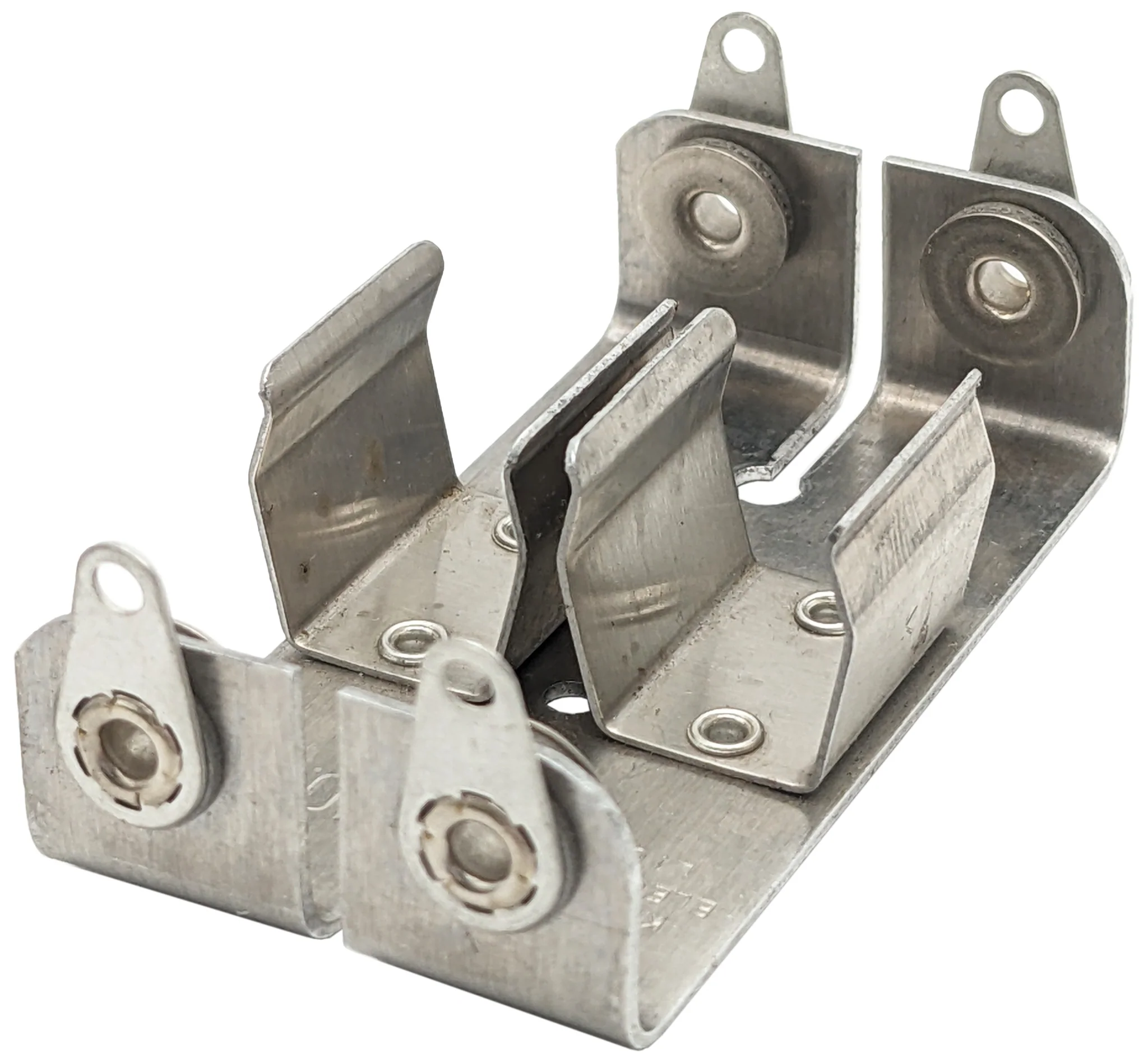

Introduction to the guide parts of battery pack In the...

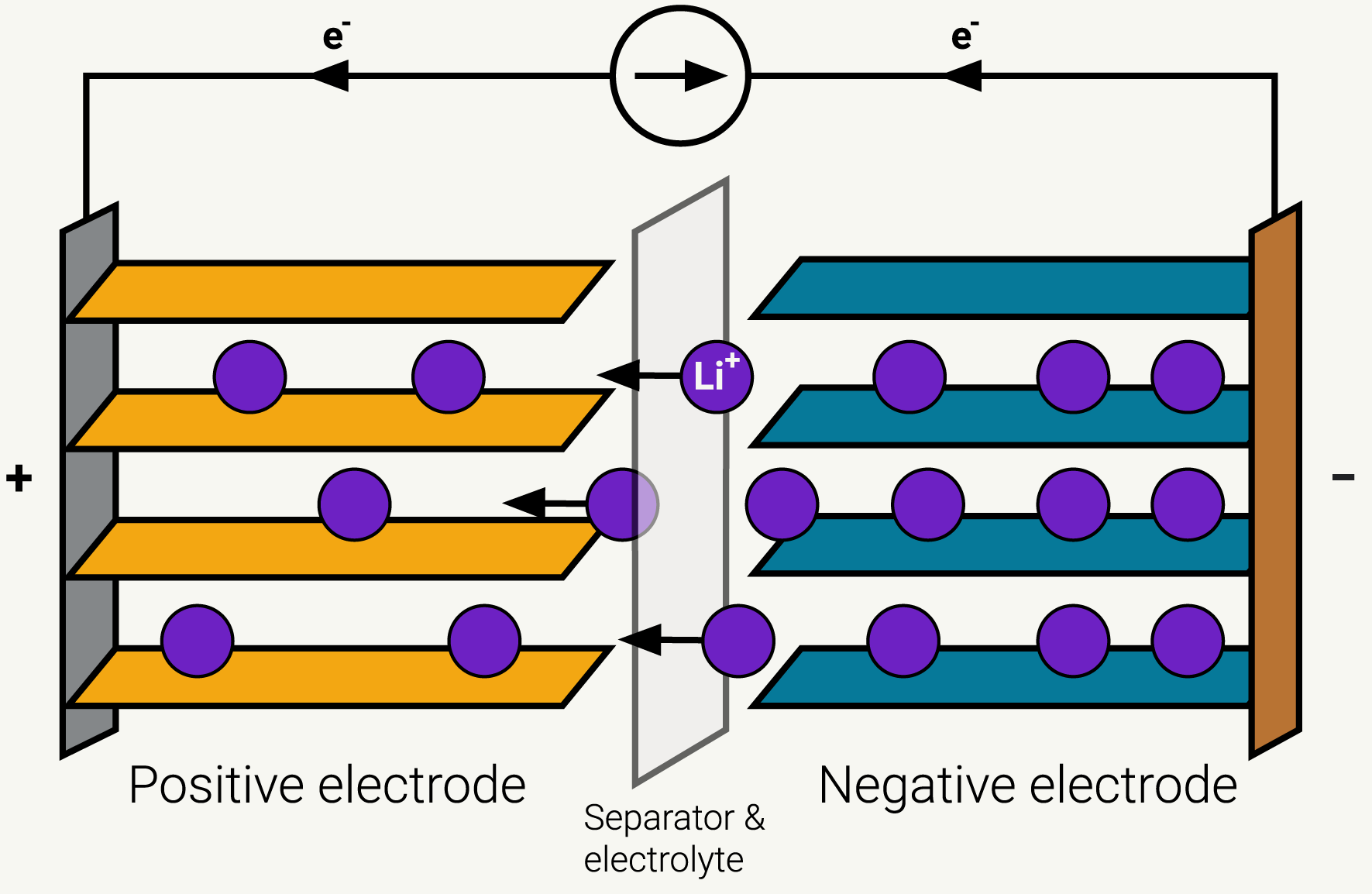

The introduction of the battery electrode

The pole plate is the core component of the battery, which has a decisive impact on the performance, energy density and cycle life of the battery. This paper will focus on the positive and negative plates of the battery, and briefly introduce their manufacturing process and testing.

The cathode material of lithium battery is a part of the materials of lithium ion battery. It directly determines the energy density, safety, cycle life and other properties of lithium battery, occupying a large proportion (the mass ratio of positive and negative materials is 3: 1~ 4:1).

The main raw materials for producing cathode materials include nickel sulfate, manganese sulfate, cobalt sulfate, nickel metal, battery grade lithium carbonate, battery grade lithium hydroxide, and main auxiliary materials include caustic soda, ammonia, sulfuric acid, etc. These raw and auxiliary materials are mainly bulk chemicals, and the market supply is relatively sufficient.

At present, the mainstream cathode materials for commercial lithium batteries include lithium iron phosphate, lithium cobalt acid, lithium manganese acid, ternary materials (NCM), etc.

The cathode material of lithium-ion battery is an important part of lithium-ion battery. The composition and structure of the cathode material have a decisive influence on the electrochemical performance of lithium-ion battery. From the brief history of the development of lithium-ion batteries, the development of cathode materials has promoted the commercialization of lithium-ion batteries. The original lithium battery used lithium metal as the negative electrode material, but lithium metal is easy to produce lithium dendrites during charging and discharging, resulting in fire or explosion and other safety problems. Then, the lithium alloy material was developed to solve the above safety problems, but the volume expansion of the alloy material was easy to occur during lithium embedding and lithium removal, resulting in a decrease in cycle performance. After further research and comparison, graphitized carbon was selected as the commercial cathode material for lithium-ion batteries. However, graphitic carbon has the characteristics of low specific capacity and poor rate performance, so the development of negative electrode materials for lithium-ion batteries is still a current research hotspot.

Although the manufacturing process of the battery pole piece is complex, it can be briefly summarized as the following main steps:

Coating: the mixed material is evenly coated on the metal substrate (positive aluminum foil, negative copper foil).

Drying: The solvent used in the coating process is removed to ensure the stability of the pole sheet.

Compaction and cutting: the density of the pole piece is increased by compaction, and finally cut into the required size according to the specifications.

These processes are crucial to the performance of the electrode chip, and controlling the process parameters can significantly improve the efficiency and life of the battery.

The test of battery electrode is a key link to ensure its reliability and performance, mainly including:

Appearance inspection: Ensure that the surface of the pole piece is free of defects, so as not to affect the performance and safety of the battery.

Electrochemical performance test: through the charge and discharge cycle test, cyclic voltammetry analysis to evaluate its capacity, efficiency, internal resistance and cycle stability.

Safety testing: including short-circuit testing, thermal deformation testing, etc., to ensure safety under extreme conditions.

The function of the test is not only to ensure the quality of the electrode, but also to provide data support for the final battery application and help to develop higher performance batteries.

Conclusion

The positive and negative plates of a battery are the basis for determining the performance of the battery, and understanding the importance of their construction, manufacturing processes and testing is crucial to driving the progress of battery technology. As the demand for high-performance batteries increases, pole chip research and development will continue to bring innovation and change to various fields such as electric vehicles, energy storage systems, and portable electronic devices.

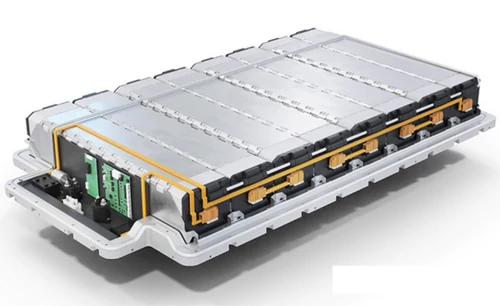

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

Function analysis of battery pack housing

Function analysis of battery pack housing Battery pack housing is...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.