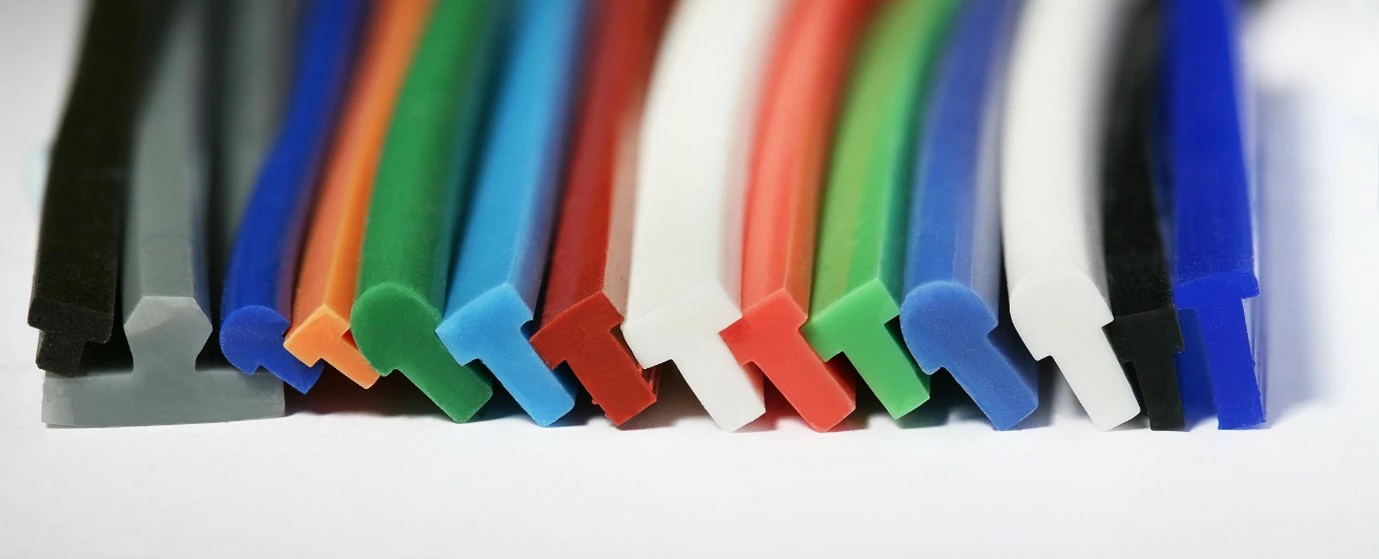

Rectangular seal ring In mechanical equipment and industrial applications, the...

Polypropylene (PP)

Polypropylene is a commonly used thermoplastic. It is found that its excellent properties make it widely used in the production of battery pack case. With the rapid development of electric vehicles and renewable energy storage systems, the safety, weight and cost of battery packs have become important design considerations. Polypropylene is the ideal material for battery pack housing due to its excellent chemical resistance, strength, toughness and economy. In this paper, the characteristics, advantages and application of polypropylene in battery pack housing will be described in detail.

basic characteristics of polypropylene

Chemical resistance: Polypropylene has good resistance to a variety of chemicals, including acids, bases and salts. This feature enables PP materials to effectively resist the corrosion of electrolytes and other chemicals in the battery environment, protecting the safety and performance of the battery.

Strength and toughness: The tensile strength and impact toughness of polypropylene are high, so that it remains structurally stable under various mechanical stresses. This characteristic ensures that the battery housing is not easily broken under extreme conditions such as collision and vibration, providing good protection.

Lightweight: The relatively low density of polypropylene makes the battery pack case made with it lightweight. This is particularly important for applications such as electric vehicles that require improved energy efficiency and range, reducing overall weight and improving athletic performance.

Easy to process: polypropylene can be processed by injection molding, extrusion, blow molding and other ways. This flexibility of processing enables high efficiency and large-scale manufacturing in the production process, reducing production costs.

Cost-effectiveness: Compared with other engineering plastics, polypropylene has a lower raw material cost, so it has a good cost performance in mass production, optimizing the cost structure of the battery pack.

the application of polypropylene in the battery pack housing

Polypropylene is widely used in the manufacture of battery packs, and its main application areas include:

Electric vehicle batteries: With the expansion of the electric vehicle market, the safety and reliability of battery packs are particularly important. The chemical resistance and toughness of polypropylene make it the best choice for battery pack housing, providing effective protection for batteries.

Energy storage systems: In stationary energy storage and renewable energy systems, the polypropylene housing can effectively protect the internal battery cells, ensuring the safe and stable operation of the system in different environments.

Portable electronic equipment: Polypropylene's lightness and good processability make it a common material for portable electronic device battery casings, meeting the needs of consumers for lightweight and portability.

Large industrial batteries: In industrial applications requiring high-density power, the durability and reliability of the polypropylene housing ensure effective protection of the battery pack in harsh environments and improve the efficiency of the equipment.

the future outlook of polypropylene

With the continuous progress of science and technology and the development of battery technology, the application prospect of polypropylene in battery pack housing is broad. Possible future trends include:

Modified polypropylene: Through the addition of glass fiber, nanomaterials and other modifiers, improve the performance of polypropylene, including improving its thermal stability, impact resistance, etc., to adapt to a more demanding working environment.

Research and development of recyclable and environmentally friendly materials: With the increasing awareness of environmental protection, the development of renewable and degradable polypropylene materials to reduce the impact on the environment and waste of resources will be an important direction in the future.

Smart battery housing: Sensors are integrated into the polypropylene housing for real-time monitoring of battery status, improving safety and user experience.

conclusion

Polypropylene (PP) is an ideal material for battery packs because of its excellent chemical resistance, strength, toughness and economy. Its lightweight, easy to process characteristics make mass production efficient and cost controllable. In the future development of battery technology, the application of polypropylene will continue to expand, providing an important guarantee for the safe and reliable operation of electric vehicles and renewable energy storage systems. With the continuous emergence of new materials and new technologies, the performance of polypropylene will be further improved, promoting innovation and progress in the battery industry.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

Application of rubber material in battery pack housing

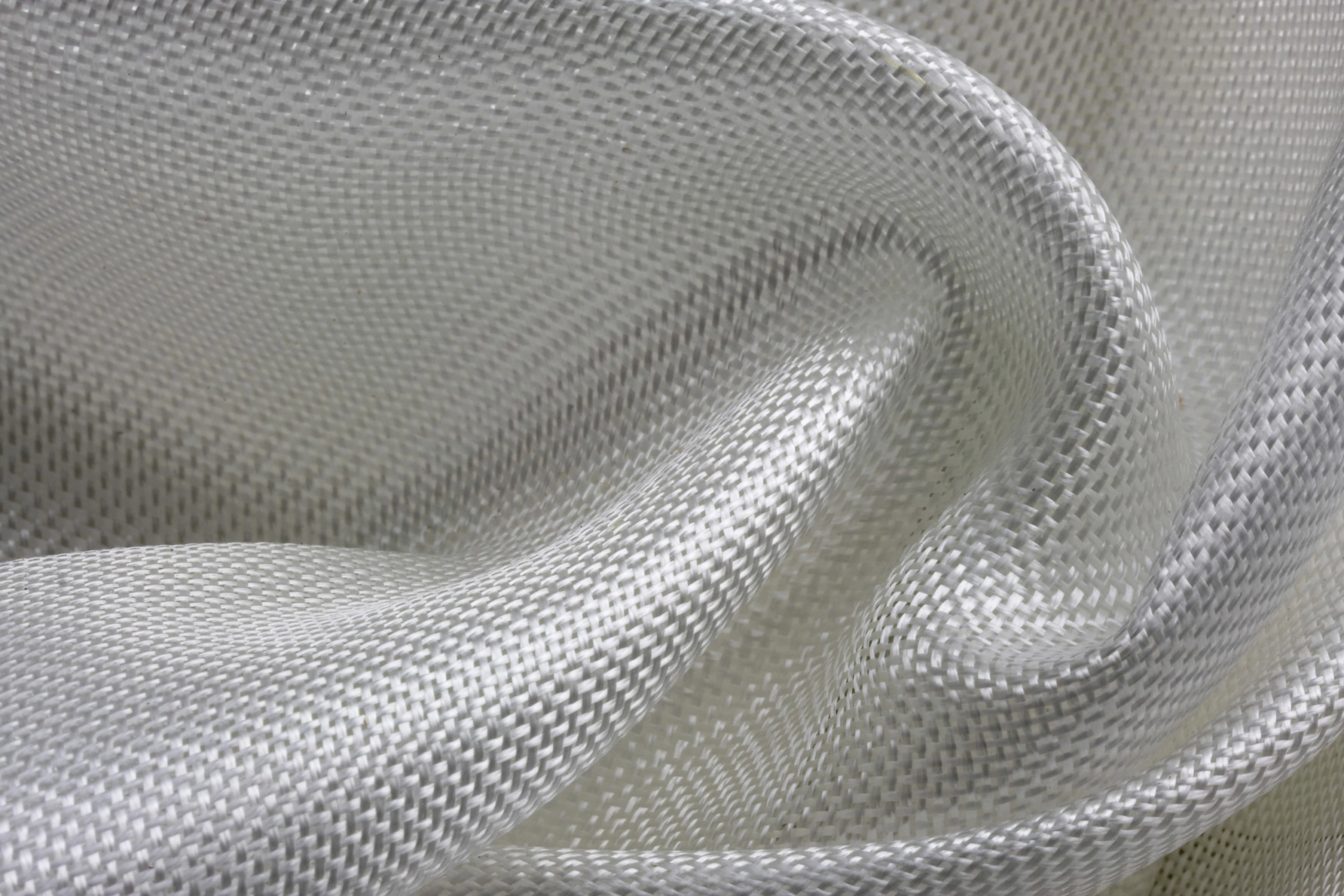

Glass fiber composite material Glass fiber composites have been widely...

Glass fiber composite material

Glass fiber composite material Glass fiber composites have been widely...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.