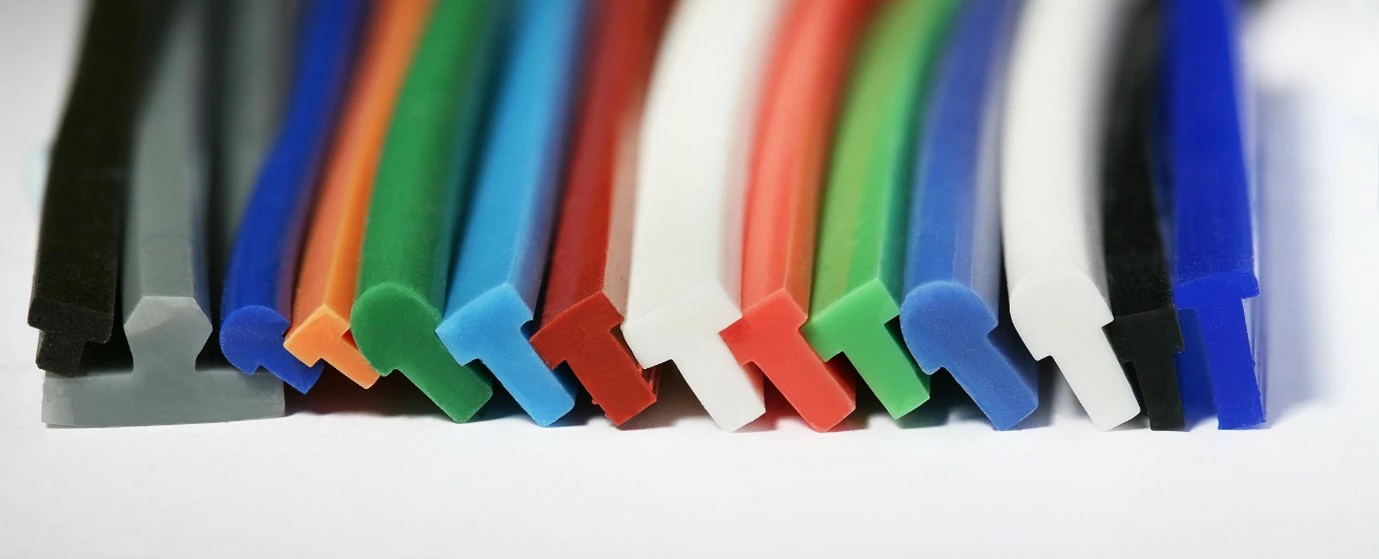

Rectangular seal ring In mechanical equipment and industrial applications, the...

Liquid cooling plate seal ring

Liquid cooling plate seals are a crucial component in battery cooling systems and are widely used in electric vehicles, battery energy storage systems and other high-performance electronic devices. It is mainly used to seal the connection between the liquid cooling plate and the battery pack, ensuring the effective flow of the coolant, while preventing leakage and external contamination. With the rapid development of the electric vehicle industry, liquid cooling technology has received more and more attention, and the performance of the liquid cooling plate seal ring directly affects the safety and efficiency of the battery. In this paper, the importance of seal ring of liquid cooling plate will be discussed in detail from the aspects of structure, function, material and application.

the structure and function of the liquid cooling plate seal ring

Liquid cooling plate seals are usually made of elastic material and are designed to withstand pressure changes and temperature fluctuations within the liquid cooling system. Its main structure and functions include:

Sealing function: The main function of the liquid cooling plate seal ring is to prevent the leakage of coolant and ensure the normal operation of the cooling system. At the same time, the sealing ring also prevents external contaminants from entering the system.

High temperature and corrosion resistance: In battery systems, coolants may contain a variety of chemical compositions. The liquid cooling plate seal ring needs to have good high temperature and corrosion resistance to ensure long-term stable performance.

Flexibility: The design of the seal ring is usually with a certain degree of flexibility, so that it can adapt to the small displacement generated by the battery and cooling system in the process of thermal expansion and contraction, so as to maintain a good sealing effect.

Bearing capacity: the seal ring of the liquid cooling plate can withstand the pressure from the coolant to prevent leakage or damage caused by excessive pressure.

the material selection of liquid cooling plate sealing ring

The performance of the liquid cooling plate seal ring is directly related to the selected material, commonly used materials include:

Silicone rubber: Silicone rubber has good high temperature resistance and chemical stability, which is very suitable for use in liquid cooling environments. Its excellent elasticity and cold resistance make it maintain a good sealing effect during the thermal cycle.

Fluororubbers (FKM) : Fluororubbers excel in chemical resistance and high temperature resistance, making them suitable for high-end applications where corrosive coolants need to be handled.

Polyurethane: Polyurethane seals are widely used in liquid cooling systems because of their excellent wear resistance and elasticity.

EPDM (ethylene-propylene rubber) : EPDM has good heat and weather resistance, and is suitable for liquid cooled battery systems with high environmental requirements.

Choosing the right material can effectively improve the service life and reliability of the liquid cooling plate seal ring to ensure the safety and stability of the battery system.

the application field of liquid cooling plate seal ring

Liquid cooling plate seals play an important role in the following key areas of application:

Electric vehicles: With the rapid development of the electric vehicle market, liquid cooling systems have become standard in modern battery management. The liquid cooling plate seal ring effectively prevents coolant leakage and contamination, ensuring that the battery is efficient. Work under high performance temperature control.

Energy storage systems: Large energy storage devices usually need to maintain a stable operating temperature to improve efficiency. The sealing performance of the liquid cooling plate seal ring helps maintain the cooling efficiency and improve the overall performance of the system.

High-performance electronic equipment: such as computer servers and data centers, liquid cooling systems can effectively reduce equipment temperature and prevent overheating. The good sealing performance of the sealing ring ensures the effective operation of the coolant.

Aerospace and military equipment: in high temperature, high pressure and extreme environments, liquid-cooled plate seals ensure stable operation and safety.

conclusion

Liquid plate seals play a vital role in modern battery cooling technology, ensuring the safety, stability and efficiency of the cooling system. Through in-depth analysis of their structure, materials and applications, we can better understand the importance of liquid cooled plate seals in different fields. Looking to the future, with the advancement of technology and the wide application of electric mobile devices, the performance and function of liquid cooling plate seals will continue to be improved, providing more guarantees for the further development of battery technology.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

Application of rubber material in battery pack housing

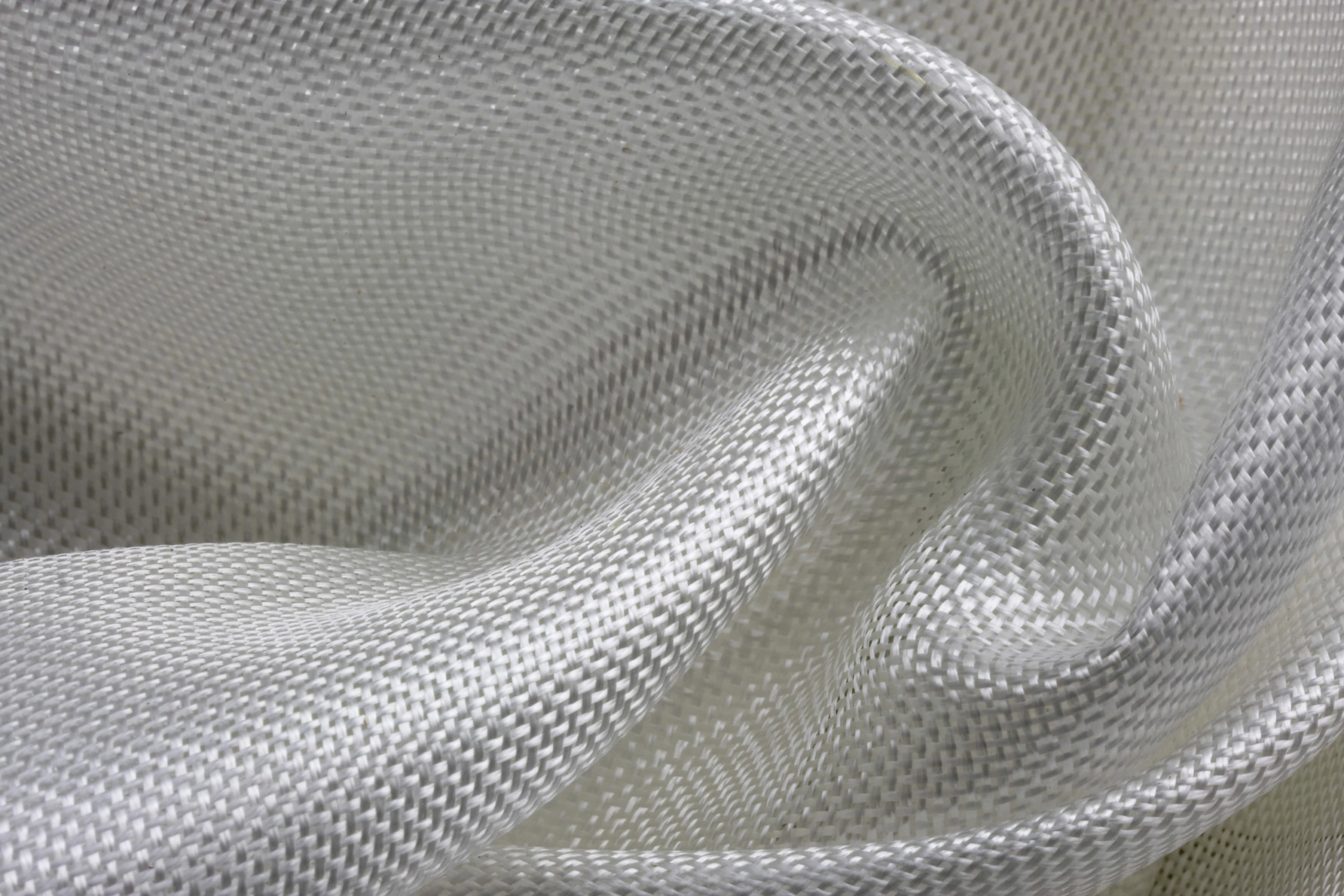

Glass fiber composite material Glass fiber composites have been widely...

Glass fiber composite material

Glass fiber composite material Glass fiber composites have been widely...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.