Dc charging pile display chip Framebuffer Main component Concept: The...

Introduction to thermoplastic polyurethane (TPU) for gun head protective covers

The thermoplastic polyurethane (TPU) of gun head protective covers is a high-performance material that is widely used in various industrial and military fields. The following is a detailed introduction to the concept, function and working principle of the TPU gun head protective cover:

Main component

concept

TPU, the full name of Thermoplastic polyurethane elastomer rubber (Thermoplastic polyurethanes), is a new polymer environmental protection material between rubber and plastic. It has both the softness of rubber and the hardness of hard plastic. TPU gun head protective cover is a protective cover made of TPU material for protecting the gun head (such as the nozzle of a plasma cutter gun).

Function

Protecting the nozzle: The main function of the TPU gun head protective cover is to protect the nozzle and avoid contact with materials such as steel plates during cutting, so as to prevent the nozzle from being burned out and extend the service life of the cutting gun.

Cooling effect: The vent hole on the protective cover can play a guiding role in the cooling gas in the welding gun, which can not only cool the cooling gas to the welding gun, but also avoid the influence of the cooling gas caused by the outflow of the nozzle on the plasma arc and avoid affecting the welding and cutting results.

Environmental adaptability: TPU materials are resistant to wear and extreme environments and have good air permeability.

Working principle

Structural design: TPU gun head protective cover usually includes an insulating porcelain sleeve, a compression ring and a conical protective cover. The outer wall of the insulating porcelain sleeve is threaded with the inner wall of one end of the pressing ring, and the outer wall of the large-diameter end of the protective cover is provided with a fixed ring, which is located between the convex ring and the insulating porcelain sleeve end and is respectively contacted with the two.

Diversion cooling gas: Several vents are opened on the cone of the protective cover, which can play a role in the diversion of the cooling gas in the welding torch, both cooling the welding torch and avoiding affecting the plasma arc.

Prevent molten metal from blowing back: During the plasma cutting process, the protective cover gathers the protective air around the plasma gas column to prevent the melting metal from blowing back into the cutting gun during the cutting process, preventing the reflected heat.

In summary, the TPU gun head protective cover, using its material characteristics and structural design, plays an important role in protecting the gun head, diverting the cooling gas and preventing the reverse blowing of molten metal, and is an important tool to improve cutting efficiency and protect the safety of operators.

DC CHARGING PIlE SERIES

DC charging pile is an efficient charging facility for electric vehicles, which uses direct current (DC) to directly charge the vehicle battery, significantly reducing the charging time. Compared with traditional AC charging piles, DC charging piles are able to provide higher power output and can usually charge an EV to 80% of its capacity in 30 minutes, providing users with a convenient charging experience.

Extended reading

Power management of communication interface chip of DC charging pile

Power management of communication interface chip of DC charging pile...

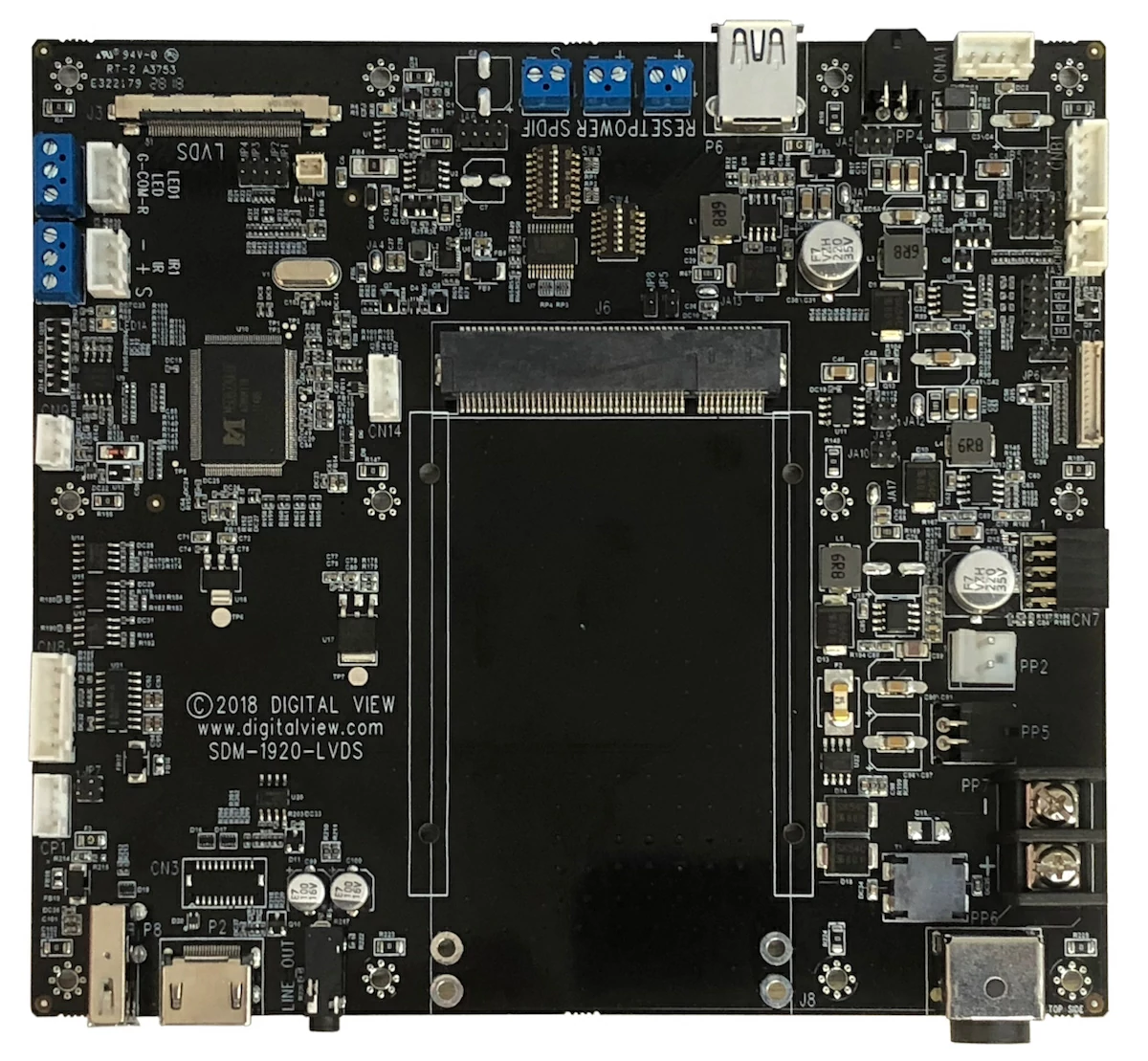

Dc charging pile display chip LVDS interface

Dc charging pile display chip LVDS interface Main component Concept:...

What is the role of the head of the communication contact

What is the role of the head of the communication...

How is the emergency stop button of DC charging pile designed?

How is the emergency stop button of DC charging pile...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.