Partition Capacity separation is a key step in the production...

Partition

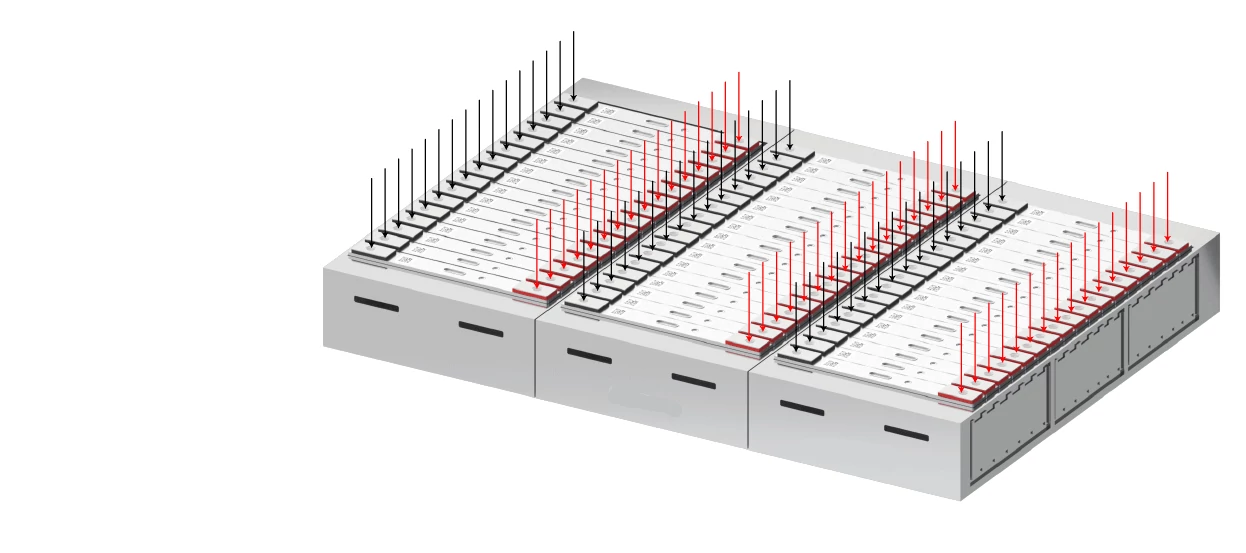

Capacity separation is a key step in the production process of lithium batteries, the main purpose of which is to carry out capacity separation and performance screening classification of batteries. The following is a detailed introduction to the volume separation process:

The concept of partitioned volume

Capacity separation refers to the fixed requirements of the environment, when the lithium-ion battery is fully charged, discharge under certain conditions, at this time the battery released electricity is the capacity of the lithium-ion battery. Lithium-ion batteries are differentiated according to capacity, that is, capacity. The capacity separation is not only conducive to the stability of SEI film, but also can shorten the time consumed by the capacity separation process, reduce energy consumption and increase production capacity.

The purpose of the volume separation

The purpose of volume separation is to distinguish capacity: qualified products and unqualified products. When the capacity meets the requirements, it is actually qualified. When the capacity is lower than the specification requirements, it is a non-conforming product. In addition, the capacity is also used for sorting, screening the internal resistance of the monomer and the same capacity of the monomer combination to ensure the performance of the battery pack consistency.

Method of dividing volume

The method of capacity separation mainly includes discharge capacity method: lithium-ion battery is fully charged under certain conditions, and then full discharge with a certain current, discharge current multiplied by time is the discharge capacity of the ion battery. When the volume is divided, the data of each detection point is managed by the computer, so as to analyze the data such as the size of the battery capacity and the internal resistance, and determine the quality level of the battery.

The role of parting volume

Quickly and accurately evaluating the capacity and performance of the battery helps users make more informed choices during purchase and use, and improves the efficiency and life of the battery.

Through the capacity division, the battery can be classified and organized, and the monomer with the same internal resistance and capacity can be combined to ensure the performance consistency of the battery pack.

After the separation, the battery needs to stand for a period of time, generally not less than 15 days, during this period, some inherent quality problems will be manifested, such as excessive self-discharge.

The process flow of separating volume

Charge: Charge the battery to the full charge state.

Discharge: Discharge the battery with a certain current, record the discharge time and current.

Capacity calculation: Calculate the capacity of the battery based on the discharge current and time.

Data analysis: Data of each detection point is obtained through computer management, and parameters such as battery capacity and internal resistance are analyzed.

Quality classification: According to the test results of the battery quality classification and classification.

CONCLUSION

Through the separation process, the performance and safety of lithium batteries can be ensured, and the efficiency and life of batteries can be improved.

EPS BATTERY SERIES

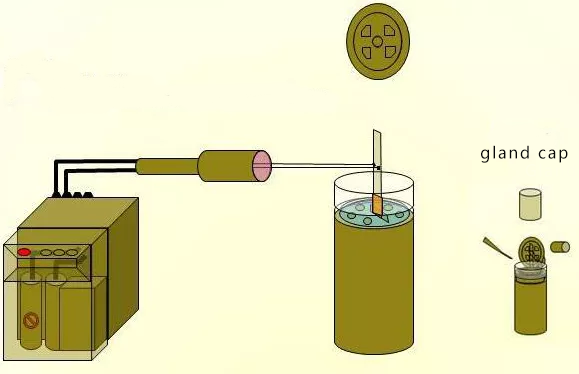

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.