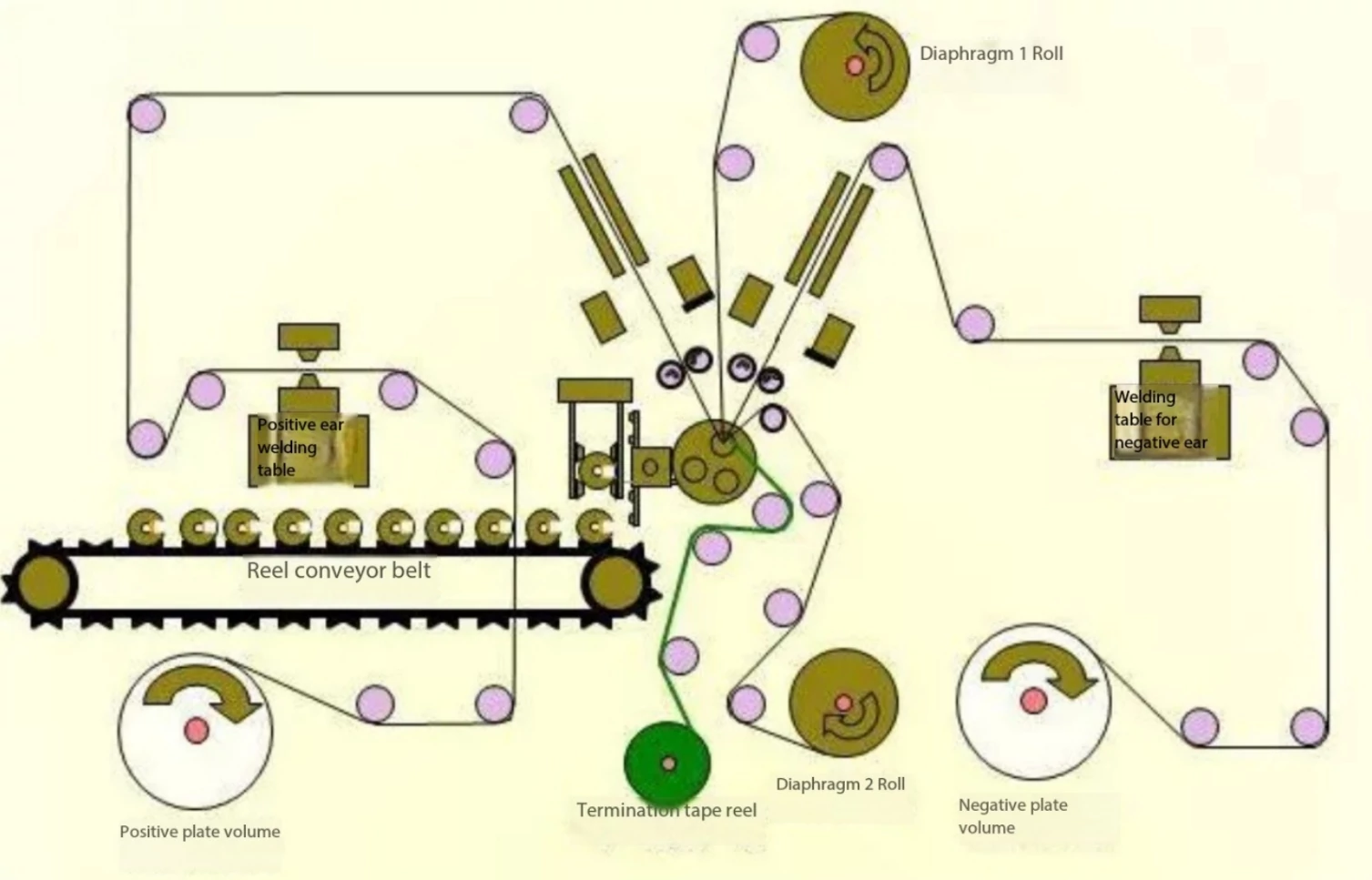

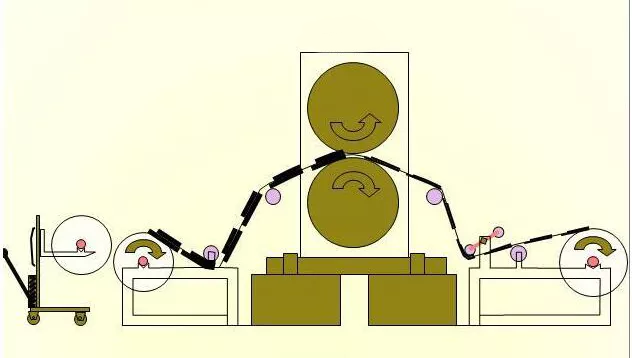

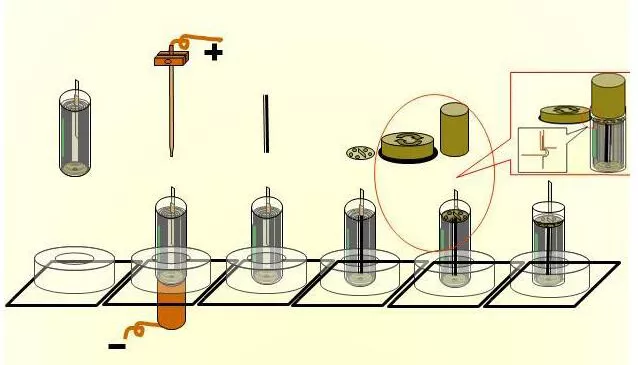

Winding The winding process of lithium battery is one of...

Dry and store

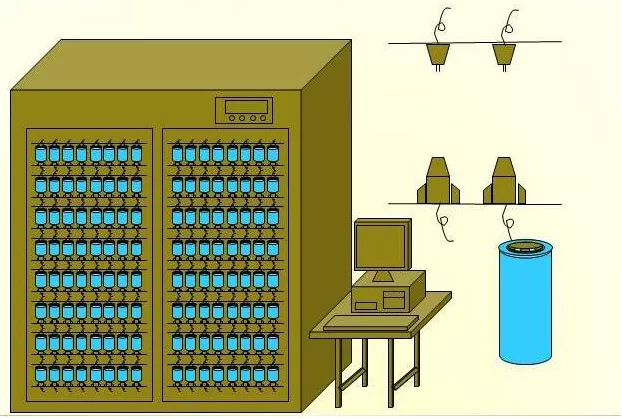

Dry storage in the production process of lithium battery is an important link to ensure the quality and performance of the battery. The following is a detailed description of the dry storage process:

Dry storage purposes

The main purpose of dry storage is to remove moisture from the battery components and prevent performance degradation or safety problems caused by moisture in the subsequent production and use of the battery. In addition, dry storage also helps prevent rust in battery metal components or battery leaks.

Dry storage process flow

Baking: Before injection, the battery needs to go through the baking process to remove the moisture inside the battery cell and ensure the quality of the battery in the subsequent production and use process.

Vacuum drying: Design the process flow and gas circulation scheme of vacuum drying of the battery cell, analyze the water composition and drying mechanism of the battery cell, and design the process scheme of vacuum drying of the battery cell.

Dry storage equipment: The design of a reasonable process flow, the proposed lithium ion power battery cell drying equipment can achieve automatic material in and out, high sealing performance, uniform drying effect.

Environmental control: During the dry storage process, the ambient temperature, dew point temperature, pressure and other parameters are controlled, the cleanliness level of air suspended particles is not less than ISO8, and the ambient air dew point temperature is below -35℃.

Technical requirements for dry storage

Baking parameters: Input parameters include baking temperature, baking time, baking vacuum degree, ventilation frequency, etc. Output parameters include baking water content.

Moisture test: The air is driven by the compression pump through two desiccant to the sample bottle, and the moisture is carried to the titration cup through the dry gas flow.

Environmental parameters: As mentioned in the operation and maintenance management procedures of the clean drying room of the lithium-ion battery factory, the environmental temperature, dew point temperature, pressure and other parameters are controlled, the cleanliness level of air suspended particles is not less than ISO8, and the ambient air dew point temperature is below -35℃.

Precautions for dry storage

Charge state: Lithium battery storage for a long time, should maintain 50%-60% of the charge state, every 3 months should be replenished, every six months should be charged and discharged.

Moisture-proof: During transportation, pay attention to moisture-proof, moisture-proof, prevent extrusion, collision, etc., so as to avoid battery damage.

Temperature control: Do not use or place the battery at high temperature, otherwise it may cause the battery to overheat, fire or function failure, and shorten the life.

Safety protection: Do not store in places with strong static electricity and strong magnetic field, otherwise it is easy to damage the battery safety protection device and bring insecurity

Hidden dangers.

CONCLUSION

Through the above dry storage process and precautions, it can be ensured that the dry storage link of the lithium battery in the production process achieves the expected effect, so as to ensure the quality and performance of the battery.

EPS BATTERY SERIES

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

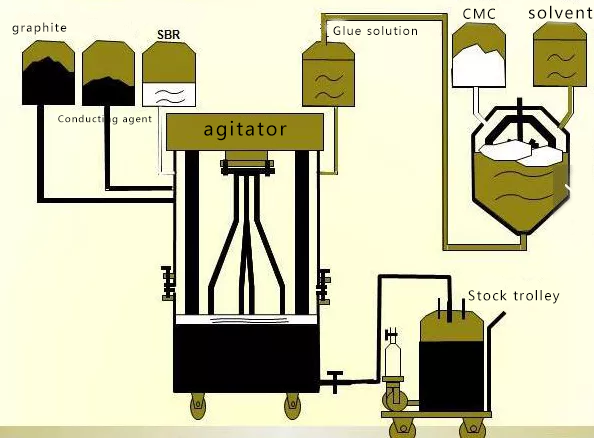

Negative homogenate

Negative homogenate Lithium batteries, especially lithium-ion batteries, are widely used...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.