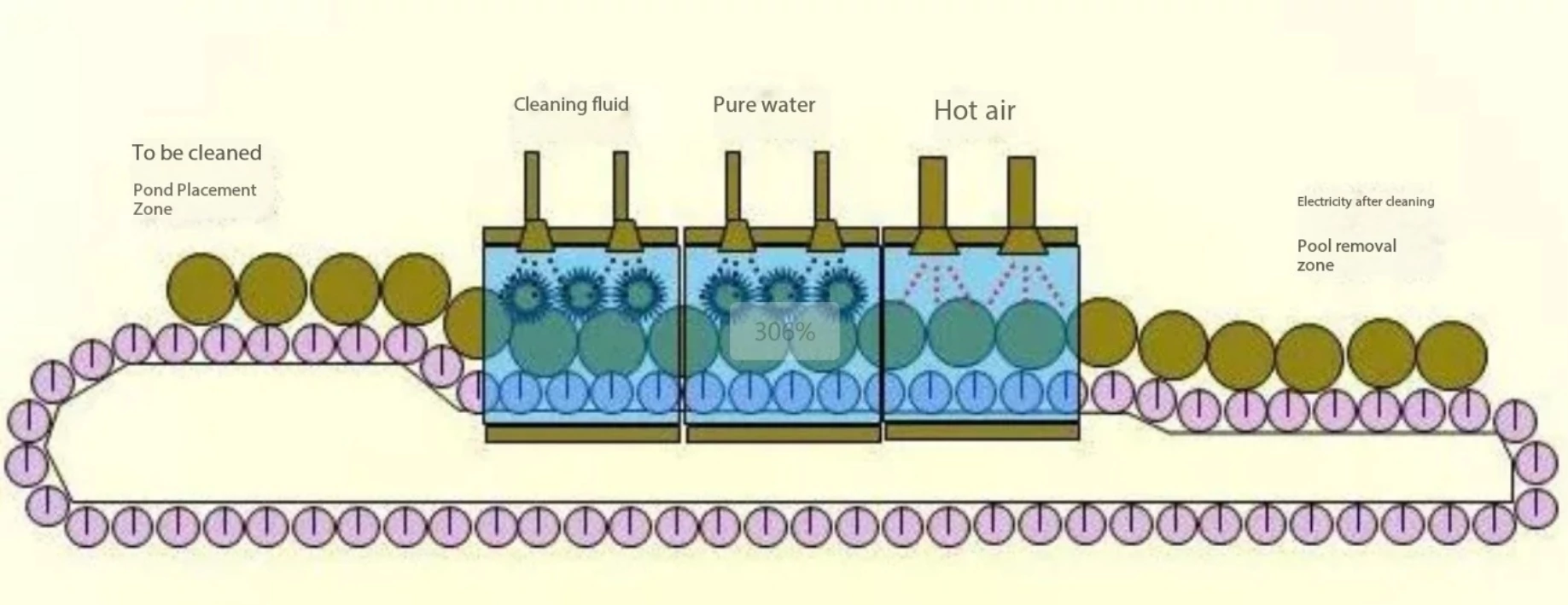

wash The cleaning link in the lithium battery production process...

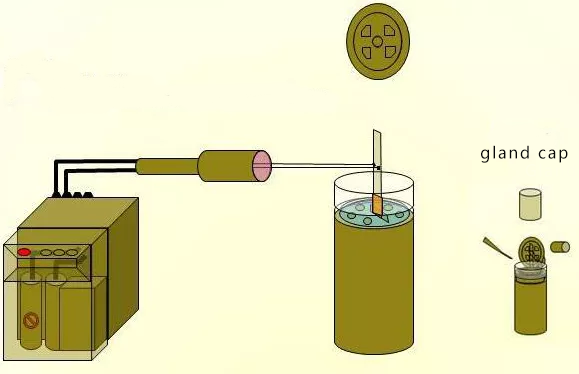

Weld cap

A key step in the lithium battery production process is the welding cap, which involves welding the positive lug of the battery to the battery cap (top cap) to ensure the battery's tightness and electrical connection. The following is a detailed introduction to the welding cap process:

Purpose and importance of welding caps

The main purpose of the welding cap is to weld the positive ear with the battery cap (top cap) to form the positive conductive terminal of the battery and ensure the closing function of the battery. This step is essential for the structural reliability, consistency and safety of the battery.

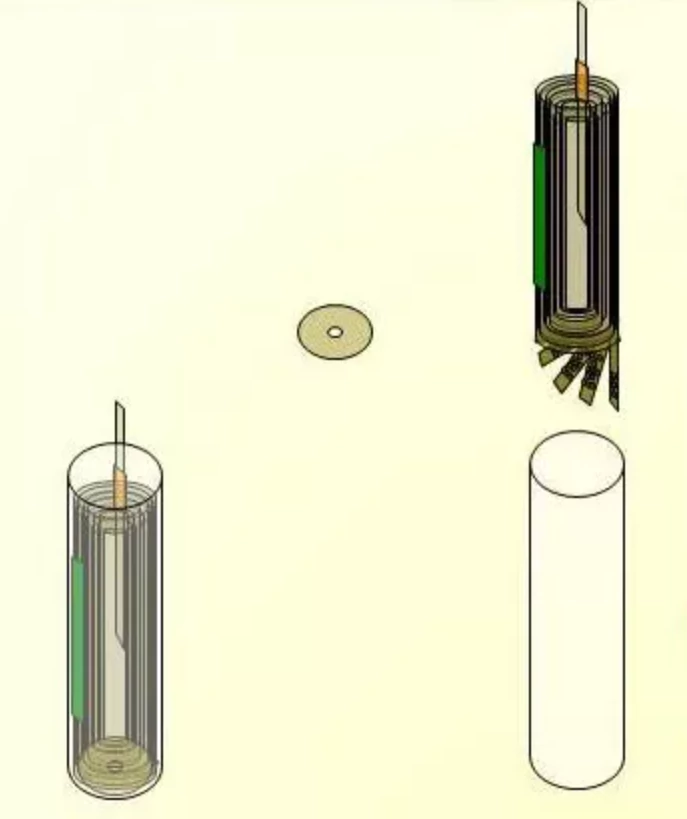

Welding cap process flow

heet selection: Select the sheet material with no arc point, no crack and no curved surface deformation, which is usually domestic 08f low-carbon cold-rolled steel.

Sheet softening: The sheet is softened by ultrasonic, and the ultrasonic vibration frequency is generally 20-22kHz and the amplitude is 55-60um.

Stamping: The softened sheet is put into the forming machine and slowly stamped through the upper and lower forming die.

Stamping cutting: The formed sheet is placed in the punching machine, and the scrap is cut by stamping cutting tools, leaving a number of formed round sheets.

Grinding: Put the formed round sheet into the abrasive and stir it to remove burrs and surface irregularities.

Washing: Vibration washing with high speed water flow on the polished molded round sheet to remove surface impurities.

Coating treatment: A layer of semi-bright nickel is plated on the molded round sheet after washing to enhance corrosion resistance and aesthetics, and the finished battery cap is obtained.

Welding cap technical details

Laser welding: Welding caps usually use laser welding technology, laser welding machine produces a high energy laser pulse, the positive ear and hole plate (part of the cap) metal material melted together.

Solder joint design: The solder joint design is more than two, and the adjacent solder joint partially overlaps and all the solder joints form a straight line. This design can use the heat generated by the previous solder joint to preheat the subsequent solder joints, reduce the difficulty of welding, and improve the welding strength and production efficiency.

Welding parameters: Key parameters in the welding process include power, welding speed, shielding gas, and defocusing, which affect penetration, width, flanging, and welding appearance.

Quality control of welding caps

Welding strength: The tensile strength of the solder joint needs to meet a certain standard to ensure that the pole ear will not fall off due to vibration during battery use.

Welding appearance: After welding, the welding marks of the electric core should be smooth and smooth, no bad phenomena such as fire, explosion point, virtual welding, welding leakage and welding penetration.

CONCLUSION

Through the above detailed welding cap process and technical details, it can ensure that the welding cap step of lithium battery is accurate and efficient, so as to produce a reliable structure and high safety performance of lithium battery products.

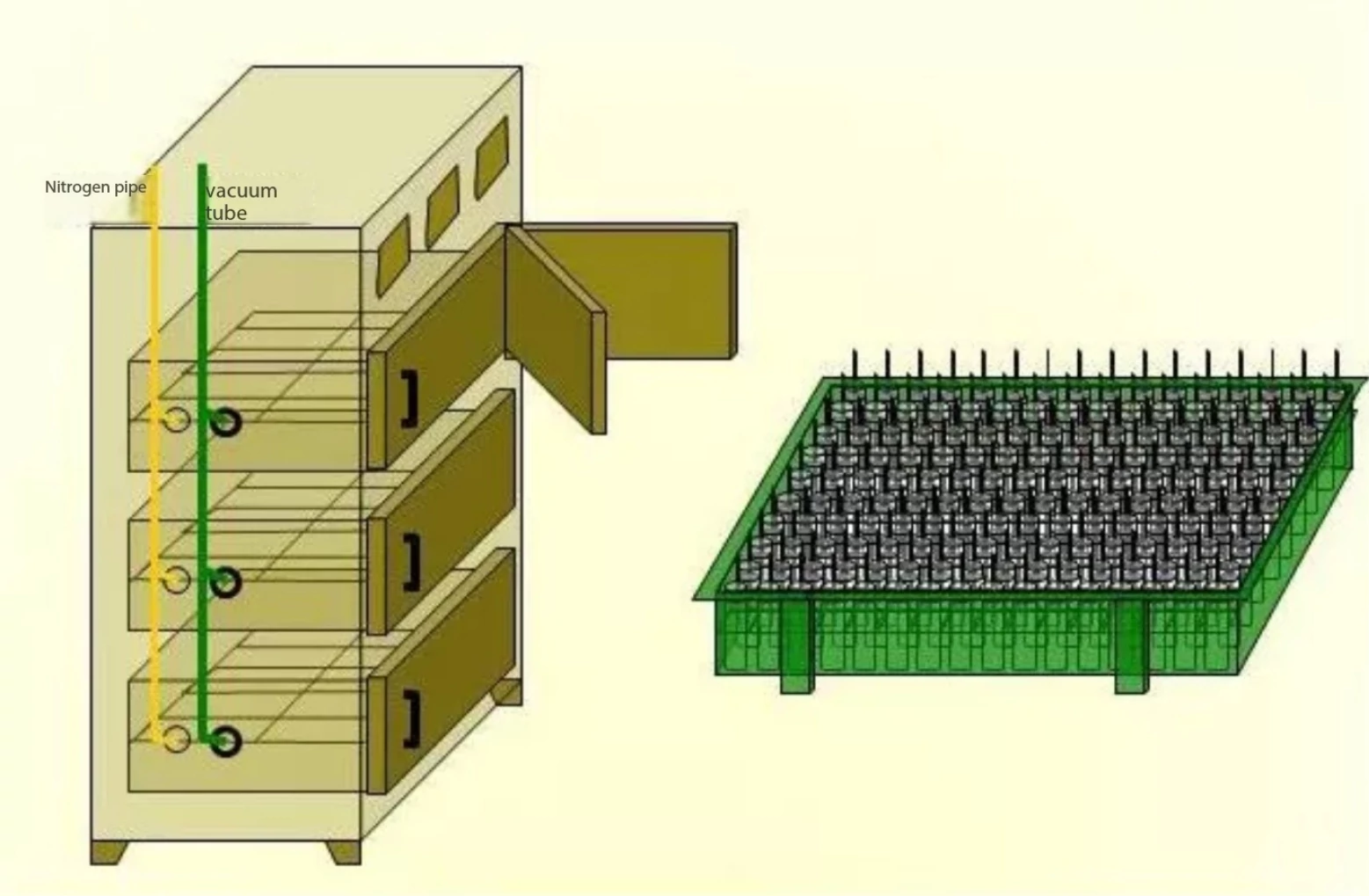

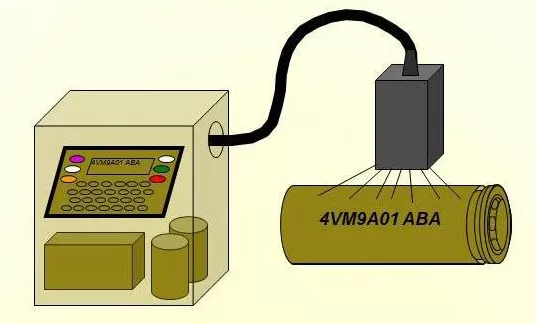

EPS BATTERY SERIES

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.