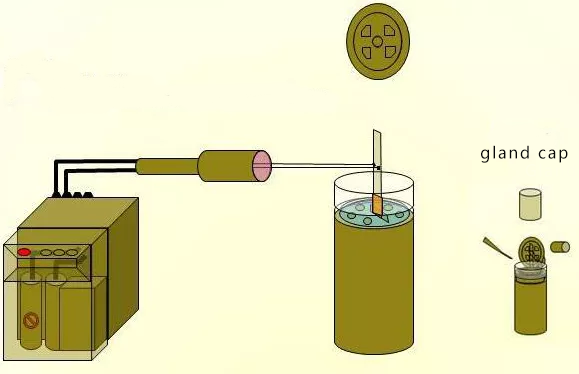

Formation Formation is a crucial step in the production process...

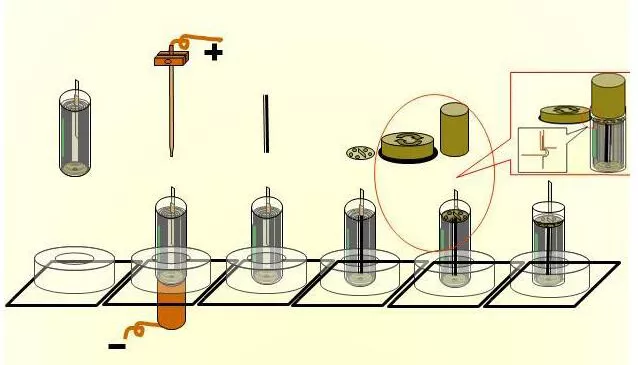

Spot welding

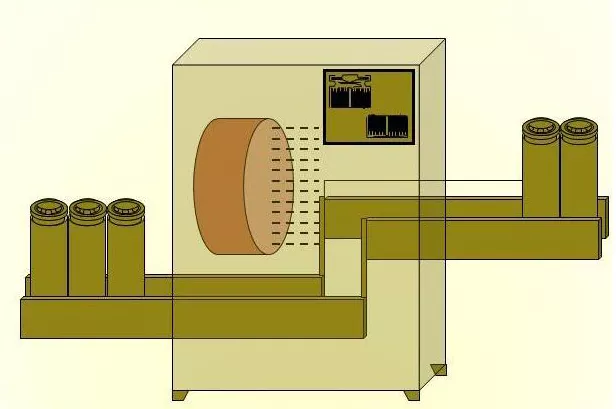

The spot welding process in the production of lithium battery is the key link to connect the battery pole, and its stability and reliability directly affect the safety and service life of the battery. The following is a detailed introduction to the spot welding process:

Principle of spot welding

Spot welding is a resistance welding technique that uses an electric current to generate heat at the contact point between two metal surfaces. The process involves passing a high current through the electrodes to clamp the material together, resulting in local melting and fusion.

Spot welding process flow

Preloading stage: Select the appropriate metal plate or part to ensure that the surface is clean and free of grease, oxides or other contaminants. Select the correct electrode material and shape, ensure that the electrode surface is smooth, and adjust the electrode pressure as needed.

Clamping stage: The material to be welded is placed between the electrodes of the spot welder, and the position is adjusted so that the welding point is directly below the electrode. Use a mechanical or pneumatic system to apply pressure to ensure that the electrode is firmly in contact with the material.

Current application stage: Set welding current, time and electrode pressure. Press the start button to start the high current between the electrodes. The contact point quickly heats up to melting temperature, fusing the metal into a solder joint.

Cooling solidification stage: After a predetermined time, the machine automatically stops the current, allowing the solder joint to quickly cool and solidify the material. Maintain the electrode pressure until the solder joint is fully solidified, then release the electrode pressure.

Inspection and post-treatment: Check solder joint quality using visual inspection, tensile testing and other methods to ensure that there are no defects such as weak or burn-through welds. If necessary, apply additional treatment to the solder joints, such as sanding or coating.

Advantages of spot welding in battery production

Speed and efficiency: Suitable for mass production.

Minimum heat affected zone: Reduces the risk of damage to sensitive battery components.

Strong and reliable connection: Spot welding is essential for the integrity of the battery pack, which resists vibration and ensures long-term reliability.

No additional materials: Spot welding does not require additional materials such as electrodes or gases, thus reducing costs.

Limitations of spot welding

Only conductive materials: Spot welding mainly acts on conductive materials. Non-conductive materials cannot be joined in this way.

Material thickness: Spot welding is usually limited to joining relatively thin metal plates. Thicker materials may require more powerful equipment or other welding techniques.

High initial investment: Spot welding equipment is expensive, especially for mass production.

Operator expertise: Spot welding requires a high level of skill and precision. Improper technology will lead to unstable welding quality, affecting battery performance and safety.

Limited range: Spot welding can be challenging for components located within narrow or hard-to-reach areas of the battery pack.

CONCLUSION

Spot welding plays a crucial role in the production of lithium batteries, and its accuracy and stability have a direct impact on the performance and safety of batteries. By optimizing the spot welding process, the production quality and efficiency of lithium batteries can be improved.

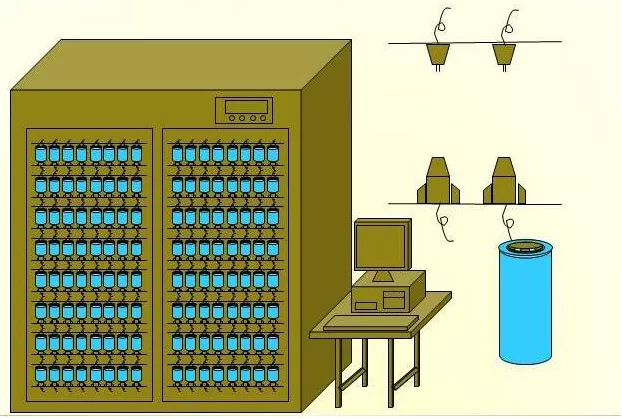

EPS BATTERY SERIES

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.