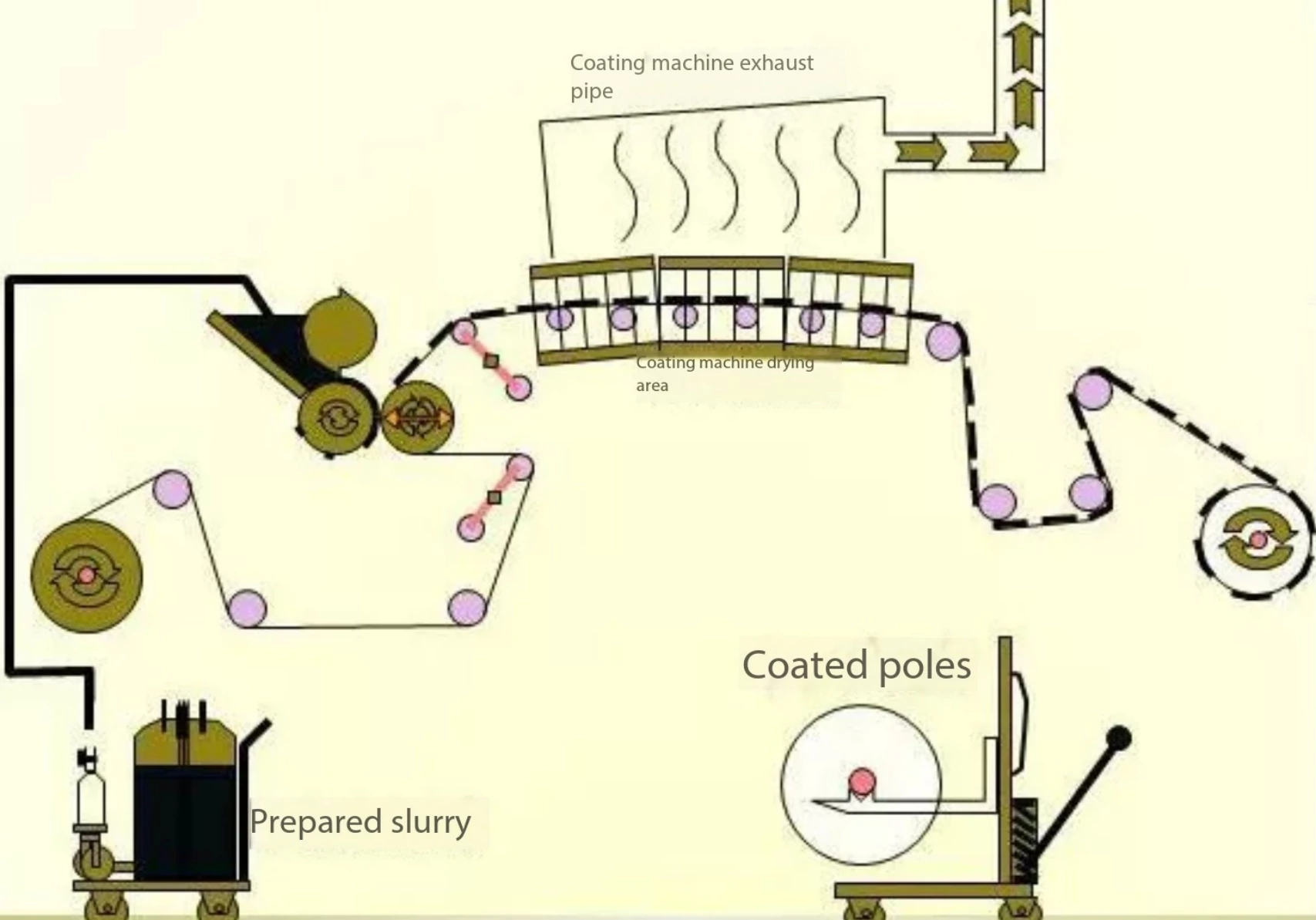

apply Lithium battery coating is a key step in the...

Enter the hell

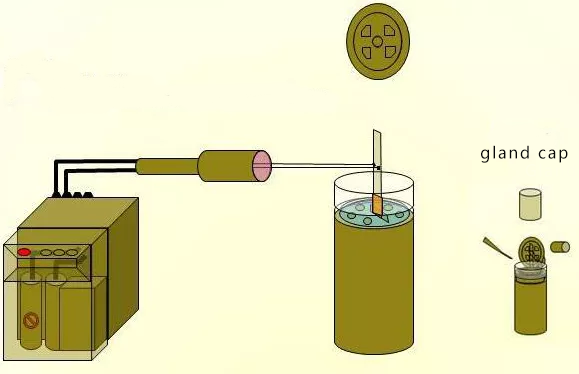

The encapsulation process of lithium battery is a key step in the cell assembly process, which involves loading the wound or laminated forming cell into the battery housing, and ensuring the connection and sealing between the cell and the housing. The following is a detailed introduction to the shell process:

Shell preparation

In the shell process, it is first necessary to prepare suitable battery shell materials. Commonly used materials include metals (such as aluminum and stainless steel) and plastics. The choice of materials should be considered according to the size, shape and application environment of the battery.

Encapsulation process

Cell loading: The wound or laminated cell is placed in the battery housing. This step requires precise control to ensure that the cell is properly placed inside the housing and that there is no damage to the diaphragm or electrodes.

Bottom welding: After the battery cell is loaded into the housing, the negative ear needs to be connected with the housing, so that the entire housing becomes the negative terminal of the battery. This step is usually achieved by welding, and the quality of the welding directly affects the safety and reliability of the battery.

Rolling groove fixing: The battery cell inside the shell is fixed through the rolling groove machine to prevent the battery cell from displacing or deforming during the use of the battery.

Pre-welding: After the cell is loaded into the housing and fixed, pre-welding is performed, which is to pre-weld the top cover of the cell with the edge of the housing to prepare for subsequent sealing.

Technological innovation and safety measures

Nanomaterials and conductive glue: The use of nanomaterials and conductive glue for electrode connection, improve the reliability of connection and conductive performance, while reducing the internal resistance of the battery, improve the battery charging and discharging efficiency.

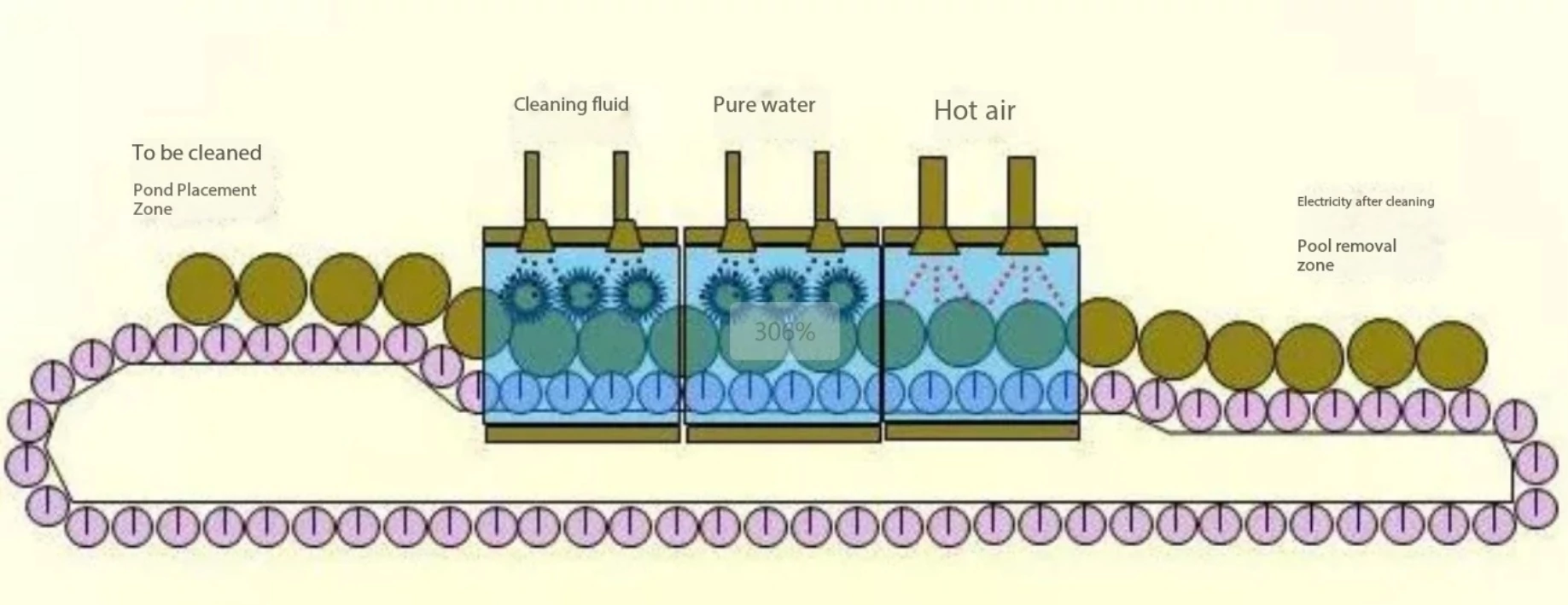

Automated assembly system: to achieve efficient and accurate assembly of batteries, reduce the human factor brought by manual operation, improve production efficiency and product quality.

Safety reinforcement: In order to prevent the risk of leakage and short circuit, a series of safety reinforcement measures will also be taken in the shell process, such as ensuring the tightness between the battery cell and the shell, and setting an insulating layer between the battery cell and the shell.

Quality control

The quality control of the shell process includes the inspection of the size, shape and surface condition of the cell, as well as the inspection of the welding quality to ensure that there are no problems such as virtual welding, partial welding and poor appearance of the cap.

CONCLUSION

Through the above steps, the shell process ensures the correct connection and sealing between the lithium battery cell and the shell, laying a solid foundation for the safety and stability of the battery.

EPS BATTERY SERIES

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.