Introduction of unlocking process in electronic locking mechanism of gun...

Flexible Graphite Composite Electrical Grounding Material (FGCGM) in Grounding Contacts

Flexible Graphite Composite Electrical Grounding Material (FGCGM) is a specialized material designed for effective grounding applications, particularly in environments where flexibility, thermal conductivity, and electrical performance are essential. This material combines the benefits of flexible graphite with polymer or composite matrices to create a versatile grounding solution. Here’s an overview of its properties, advantages, and typical applications:

Main component

Key Properties

Conductivity:

Electrical Properties: FGCGM possesses excellent electrical conductivity, allowing for effective grounding by providing a low-resistance path to ground.

Thermal Conductivity: It also showcases notable thermal conductivity, which helps dissipate heat and can enhance the reliability of electrical systems under thermal stress.

Flexibility:

FGCGM is designed to be flexible, making it easy to conform to different shapes and surfaces. This flexibility is critical for applications where space constraints and complex geometries are present.

Resistance to High Temperatures:

Thermal Stability: Graphite can withstand high temperatures without degrading, which is beneficial in high-temperature environments such as electrical enclosures or near heat-generating components.

Chemical Resistance:

FGCGM is generally resistant to many chemicals, including acids and solvents, which is particularly important in industrial and outdoor environments where exposure to corrosive substances may occur.

Mechanical Strength:

The composite nature of the material typically enhances its mechanical properties, providing durability and reliability under mechanical stress.

Benefits in Grounding Applications

Thin and Lightweight:

The film is lightweight and can be produced to be very thin, making it suitable for modern electronics where space and weight reduction are critical.

Versatile Applications:

These films can be easily cut and shaped to fit various applications, including flexible circuits and printed circuit boards (PCBs), making them suitable for custom grounding solutions.

Cost-Effective:

Utilizing metalized polyimide films can reduce the need for heavier and more expensive grounding solutions, thereby resulting in overall cost savings in manufacturing and materials.

High Adhesion:

The conductive metal layer can be adhered strongly to the polyimide substrate, ensuring reliable connections in grounding applications that may experience movement or stress.

Advantages of FGCGM for Grounding Applications

Lightweight:

Compared to traditional metal grounding solutions, FGCGM can be significantly lighter, contributing to overall weight savings in construction and electronic assemblies.

Easy Installation:

The flexibility and formability of FGCGM make it easy to install in confined spaces or challenging configurations without compromising performance.

Reduced Corrosion Risks:

Unlike metals, graphite can resist corrosion, which ensures a long-lasting grounding solution, particularly in harsh environmental conditions.

Cost-Effective:

FGCGM can be a more cost-effective option for grounding materials, especially in bulk applications, by minimizing the need for frequent replacements.

Versatility:

This composite material can be tailored in various thicknesses and forms to suit specific grounding needs and application scenarios, making it highly adaptable.

Applications in Grounding Contacts

Electronic Devices:

FGCGM is used in various consumer electronics, industrial machinery, and telecommunications where effective grounding is critical to prevent electrical noise and interference.

Aerospace and Defense:

The high-temperature resistance and reliability of FGCGM make it ideal for use in aerospace and defense applications, where grounding is vital for safety and signal integrity.

Automotive Industry:

Automotive electronics, including sensors, control units, and other components, benefit from FGCGM to ensure solid grounding connections that are also resistant to environmental factors.

Renewable Energy Systems:

In applications like solar panels and wind turbines, FGCGM can provide effective grounding solutions that are lightweight and durable, essential for energy generation systems exposed to the elements.

Industrial Equipment:

FGCGM can be employed in heavy machinery and industrial controls to provide reliable grounding paths that withstand harsh operational conditions.

Conclusion

Flexible Graphite Composite Electrical Grounding Material (FGCGM) serves as a modern solution for grounding applications that require flexibility, durability, and excellent electrical performance. Its unique combination of properties makes it suitable for various industries, from consumer electronics to aerospace and renewable energy. By offering reliable grounding solutions, FGCGM helps to enhance the safety, performance, and longevity of electronic and electrical systems.

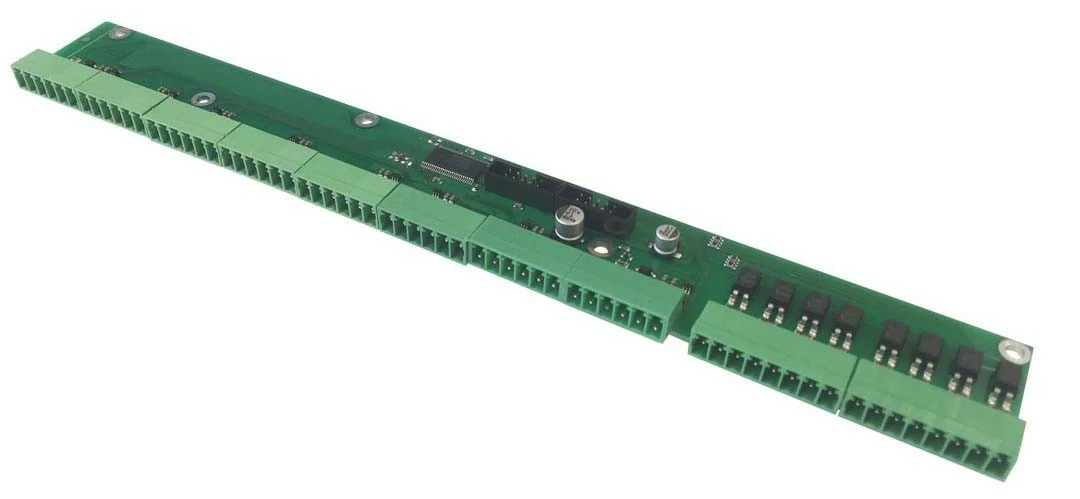

DC CHARGING PIlE SERIES

DC charging pile is an efficient charging facility for electric vehicles, which uses direct current (DC) to directly charge the vehicle battery, significantly reducing the charging time. Compared with traditional AC charging piles, DC charging piles are able to provide higher power output and can usually charge an EV to 80% of its capacity in 30 minutes, providing users with a convenient charging experience.

Extended reading

The introduction of DC charging pile filter choke coil

The introduction of DC charging pile filter choke coil In...

Contact monitoring system in gun head of DC charging pile

Contact monitoring system in gun head of DC charging pile...

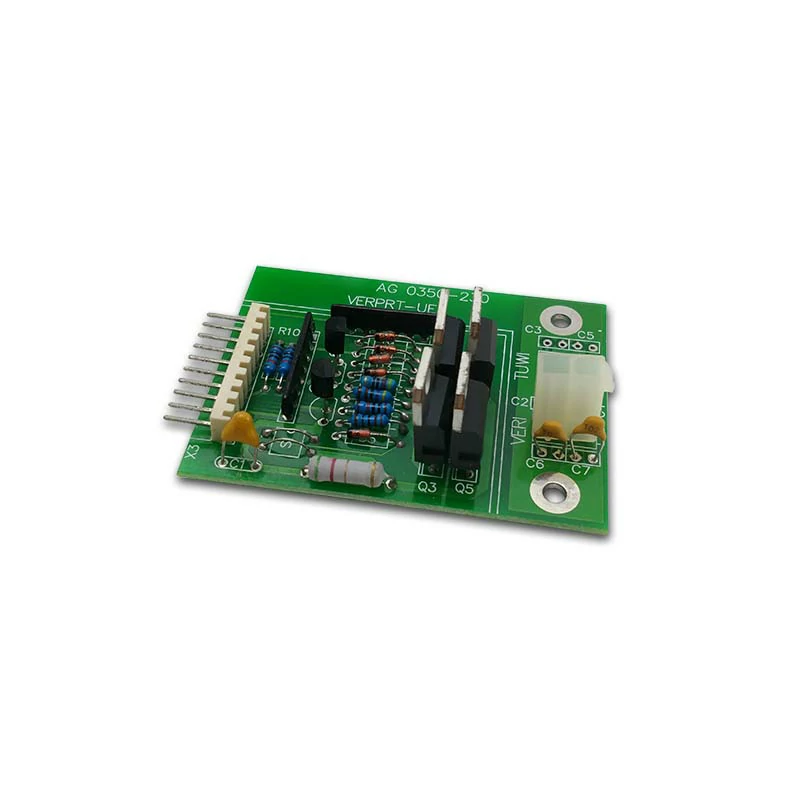

What does the electronic locking mechanism consist of

What does the electronic locking mechanism consist of The electronic...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.