What is the composition of the shell of the DC...

Introduction to the application of stainless steel plate in DC charging pile

The application of stainless steel plate in DC charging pile is multi-faceted, mainly due to its excellent corrosion resistance, high strength, aesthetics and good weather resistance. These characteristics make stainless steel the ideal material for manufacturing DC charging piles, especially in outdoor environments, where the application of stainless steel plates can ensure long-term stable operation and low maintenance costs of charging piles. Product features:

Main component

Corrosion resistance:

Stainless steel plate has excellent corrosion resistance, can resist the erosion of various climates and chemical substances, suitable for outdoor environment.

High strength:

Stainless steel plate because of its high strength characteristics, can withstand large external forces, such as car impact force and bad weather erosion.

Aesthetics:

After the stainless steel plate is polished, the appearance is smoother, increasing the weather resistance, and also improving the overall beauty of the charging pile.

Structure design:

In the structural design of the charging pile, stainless steel plates are used to manufacture the shell and key connecting parts to ensure the stability and safety of the overall structure.

Environmental adaptability:

The use of stainless steel plates allows the charging pile to adapt to the impact of outdoor extreme weather, such as dust, rain, and extreme weather.

Heat dissipation performance:

Since the charging pile will generate heat during the working process, the good thermal conductivity of the stainless steel plate helps to effectively dissipate heat and ensure the normal operation of the charging pile.

Fastener selection:

The fasteners of charging piles, such as lock rods, hinges, etc., are recommended to use 304 stainless steel material to meet the requirements of neutral salt spray resistance time GB 2423.17 not less than 96 hours.

Surface treatment:

In order to enhance the corrosion resistance and beauty of the stainless steel plate, the stainless steel parts of the charging pile are usually sprayed with outdoor powder coating or outdoor paint treatment to ensure their service life.

Application scenario: The application of stainless steel plate in DC charging pile is not only limited to the shell and structural components, but also includes key parts such as the internal support skeleton, charging interface, display area and card swipe area, ensuring the reliability and durability of the charging pile in various environments.

Summary: Stainless steel plate because of its various excellent properties, the application of DC charging pile is very important. It not only improves the durability and stability of the charging pile, but also helps to reduce long-term operation and maintenance costs, and is one of the key materials for efficient, safe and environmentally friendly charging solutions.

DC CHARGING PIlE SERIES

DC charging pile is an efficient charging facility for electric vehicles, which uses direct current (DC) to directly charge the vehicle battery, significantly reducing the charging time. Compared with traditional AC charging piles, DC charging piles are able to provide higher power output and can usually charge an EV to 80% of its capacity in 30 minutes, providing users with a convenient charging experience.

Extended reading

Introduction of ferrite magnetic beads on DC charging pile

Introduction of ferrite magnetic beads on DC charging pile With...

The introduction of insulating materials for DC charging pile transformer

The introduction of insulating materials for DC charging pile transformer...

The introduction of radiator in DC charging pile rectifier

The introduction of radiator in DC charging pile rectifier The...

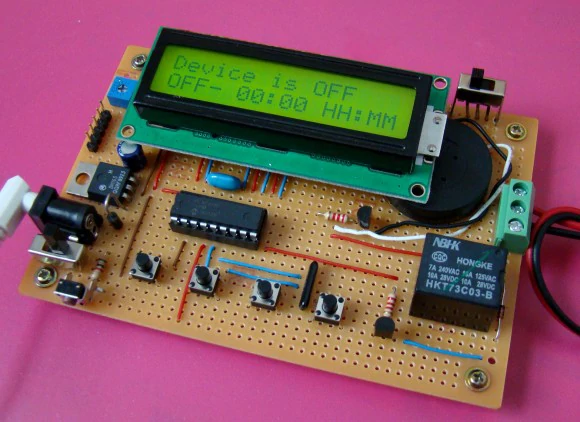

The timer of the DC charging pile microcontroller: the core of precise control

The timer of the DC charging pile microcontroller: the core...

Introduction to magnetic bead of DC charging pile filter

Introduction to magnetic bead of DC charging pile filter The...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.