EPS inverter protection circuit analysis – temperature sensor Emergency power...

Introduction of cooling pump in EPS cooling system 1

In an emergency power system (EPS), one of the key factors to ensure the stable operation of the equipment and extend its service life is effective heat dissipation management. Among them, the cooling pump, as an important part of the cooling system, plays a vital role. This paper will introduce the cooling pump in EPS cooling system in detail, including its working principle and type.

Working principle

The main function of the cooling pump is to transport the coolant from one part of the cooling system to another part, and to achieve heat absorption and dissipation through circulation flow. Its working principle can be roughly divided into the following steps:

Suction coolant: The cooling pump inhales the coolant, usually water or glycol solution, through the water intake.

Pressurized flow: the rotor in the pump rotates to generate centrifugal force, accelerating the coolant and pushing it to the water outlet.

Circulation cooling: high-pressure coolant enters the radiator or heat exchanger, exchanges heat with the equipment to be cooled, absorbs heat and then returns to the cooling pump to form a closed-loop cycle.

type

According to different application requirements and working environment, the cooling pump in the EPS cooling system can be mainly divided into the following types:

Centrifugal pump

Features: centrifugal force principle for fluid transport, simple structure, high efficiency.

Advantages: Suitable for large flow, low pressure cooling occasions, easy maintenance.

Application: Widely used in various EPS systems.

Forced circulation pump

Features: The coolant circulation is forced by the mechanical device, which can increase the velocity and flow rate.

Advantages: Suitable for high temperature, high pressure environment, can provide better heat dissipation effect.

Applications: Most used in industrial applications and high performance power equipment.

Screw pump

Features: Through the rotation of the screw, the coolant moves along the pump body.

Advantages: Suitable for conveying coolant with high viscosity, stable flow rate and wide pressure range.

Application: Suitable for specific requirements of high viscosity coolant or strict flow control requirements.

Self-priming pump

Features: With self-priming function, no need to exhaust with external equipment.

Advantages: Easier to install and maintain, suitable for small systems.

Applications: Small-scale EPS and more applications in mobile devices.

CONCLUSION

In summary, the cooling pump is the core component of the EPS inverter cooling system, and its stable operation is crucial to the performance and life of the inverter.

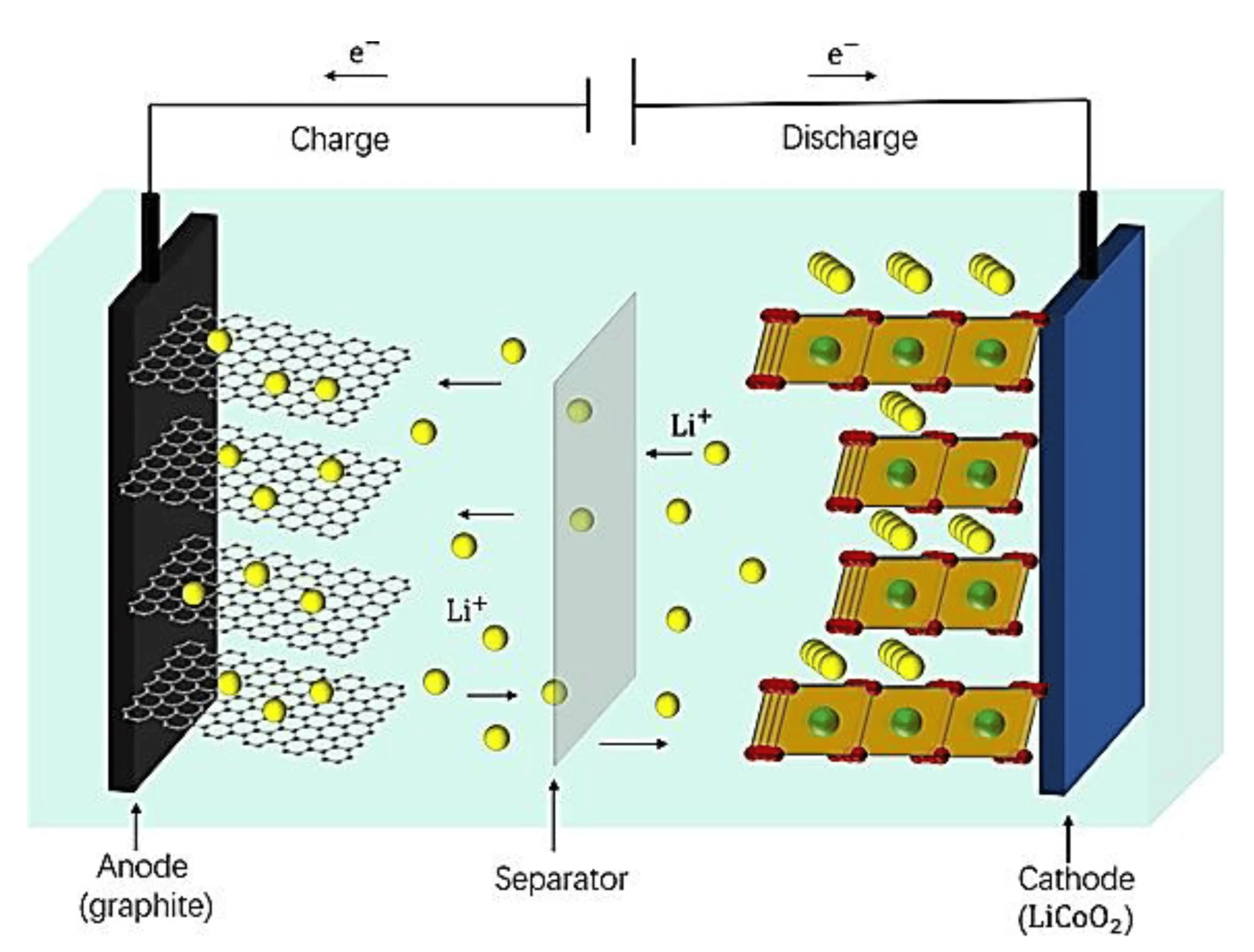

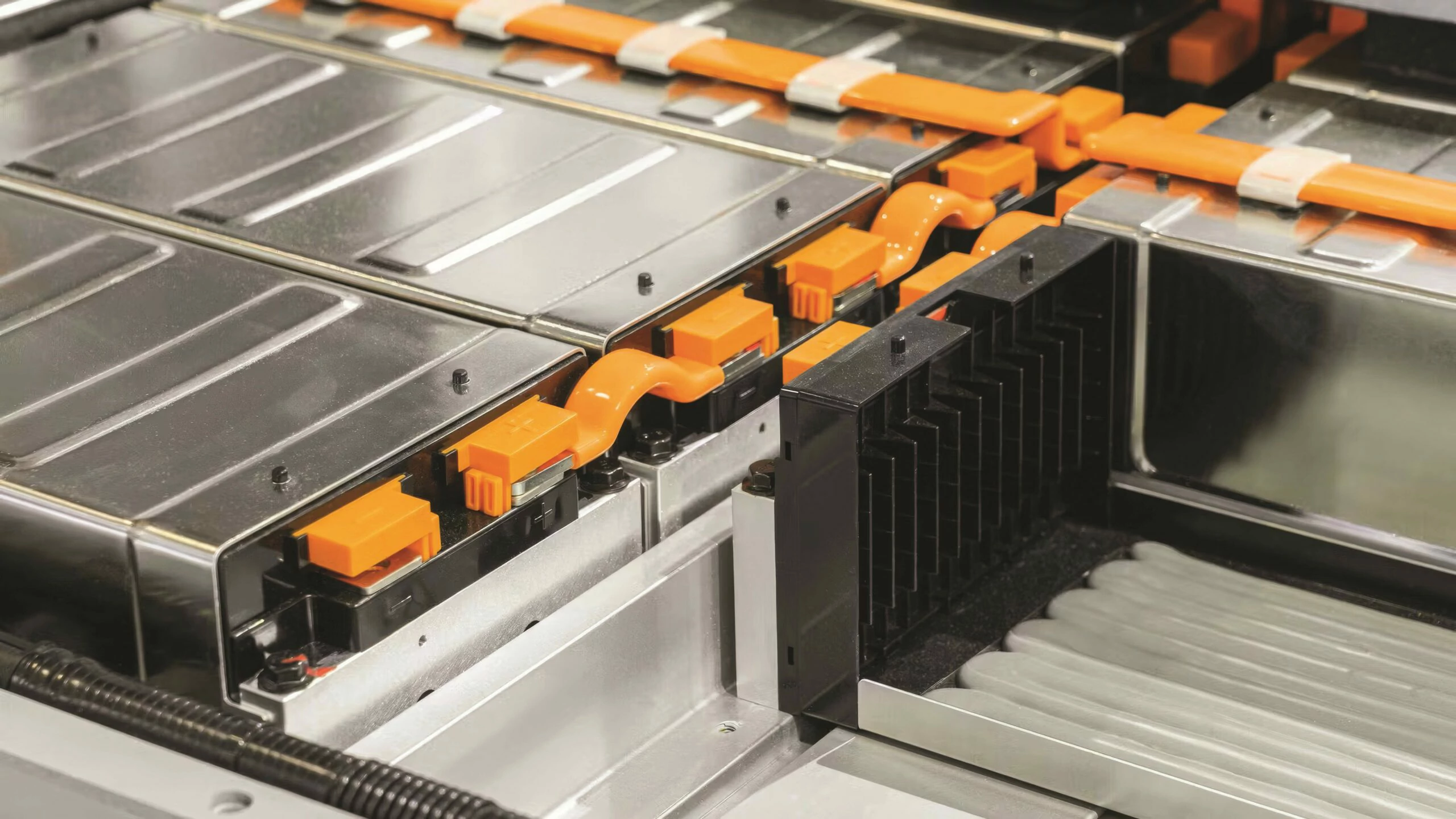

EPS BATTERY SERIES

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

What is the practical application effect of polymer electrolyte in batteries?

What is the practical application effect of polymer electrolyte in...

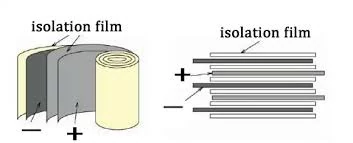

Isolation film material of EPS cell monomer: polymer

Isolation film material of EPS cell monomer: polymer In the...

Afety valves and pressure relief devices made of materials: fluorine plastic

afety valves and pressure relief devices made of materials: fluorine...

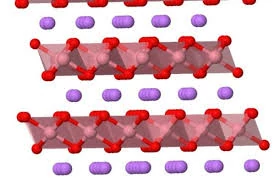

Introduction of positive electrode materials in EPS battery cell

Introduction of positive electrode materials in EPS battery cell Today,...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.