Photovoltaic module Photovoltaic module refers to solar cell module. Because...

Monocrystalline silicon solar cells: the leader in photovoltaic technology

With the growing global demand for renewable energy, solar energy is developing rapidly as a clean, renewable energy source. Among many solar cell technologies, monocrystalline silicon solar cells stand out for their high efficiency and long-term stability, becoming one of the most widely used photovoltaic technologies at present. This paper will introduce the basic concept, manufacturing process, advantages and future development trend of monocrystalline silicon solar cells.

What is a monocrystalline silicon solar cell?

Silica gel is a kind of polymer material with silicon oxygen chain as the basic structure, which has the following significant characteristics:

Excellent weather resistance

Silicone can withstand extreme temperature and humidity changes and is not easy to deform or degrade. In outdoor environments, its ability to effectively protect against UV rays makes it ideal for use in solar modules.

Good sealing performance

Silicone has excellent sealing properties, which can effectively prevent the intrusion of moisture, dust and other contaminants, thereby protecting internal electronic components.

Electrical insulation

Silica gel is an excellent insulating material that performs well in the electrical environment and can effectively prevent the occurrence of leakage events.

Flexibility and ductility

The flexibility of silicone makes it able to combine well with various materials of photovoltaic modules and adapt to different shape and size changes.

the application of silicone in solar modules

Monocrystalline silicon solar cells are photovoltaic cells made of monocrystalline silicon materials. Monocrystalline silicon is grown by a single silicon crystal, and its internal atoms are arranged regularly to form a uniform lattice structure. This structure makes monocrystalline silicon solar cells have significant advantages in photoelectric conversion efficiency and temperature stability. Second, the manufacturing process of monocrystalline silicon solar cells

the manufacturing process of monocrystalline silicon solar cells

Production of silicon ingot

The manufacturing of monocrystalline silicon solar cells begins with the production of silicon ingots, and the most common method is the "captioning method" (Czochralski method). By melting the high-purity silicon raw material with heat, a small piece of seed crystal is dipped into the molten silicon and slowly pulled out to form a monocrystalline silicon ingot.

Cut silicon

The obtained monocrystalline silicon ingots are cut into thin slices by sawing technology, which are called silicon wafers. The loss of silicon wafers should be minimized in the cutting process to improve production efficiency.

Doping and treatment

Silicon wafers are mixed with appropriate impurities (such as phosphorus or boron) to change their electrical conductivity, forming P-type or N-type silicon. This step is to improve the photoelectric conversion efficiency of the battery.

Production of battery components

The treated silicon wafer is made into a solar cell module after surface treatment, film deposition and the addition of metal electrodes. In addition, battery components are generally treated by processes such as drilling and electroplating to optimize their conductivity.

encapsulation

The finished battery assembly is encapsulated in a waterproof and durable material to provide protection and ensure its long-term use in outdoor environments.

the advantages of monocrystalline silicon solar cells

High photoelectric conversion efficiency

The photoelectric conversion efficiency of monocrystalline silicon solar cells is usually between 15% and 22%, and even the efficiency of some high-end products can exceed 26%. This allows monocrystalline silicon cells to produce more power under the same lighting conditions.

High space utilization rate

Because of their high efficiency, monocrystalline silicon solar cells can generate more power in a limited space, and are especially suitable for installation in urban or space-constrained areas.

Good performance stability

Monocrystalline silicon cells show good stability and consistency during long-term use, can withstand certain environmental changes, and their attenuation rate is relatively low.

recyclability

Monocrystalline silicon material has good environmental compatibility, can be recycled after waste, in line with the requirements of sustainable development.

the challenge of monocrystalline silicon solar cells

Higher production cost

Due to the complex manufacturing process and the high cost of energy and raw materials, the initial investment of monocrystalline silicon solar cells is relatively large.

Sensitivity to light conditions

The performance of monocrystalline silicon cells is poor under low light conditions, especially in cloudy days or insufficient light, and the conversion efficiency is relatively low.

Market competition pressure

In recent years, the rapid development of thin-film solar cells and polysilicon solar cells and other technologies has increased the competitive pressure of monocrystalline silicon cells in the market.

Summary

With its high efficiency and stability, monocrystalline silicon solar cells provide effective support for the utilization of renewable energy. In the face of cost and market challenges at the same time, with the continuous progress and innovation of technology, monocrystalline silicon solar cells will continue to play an important role in the future photovoltaic industry, helping global energy transformation and sustainable development.

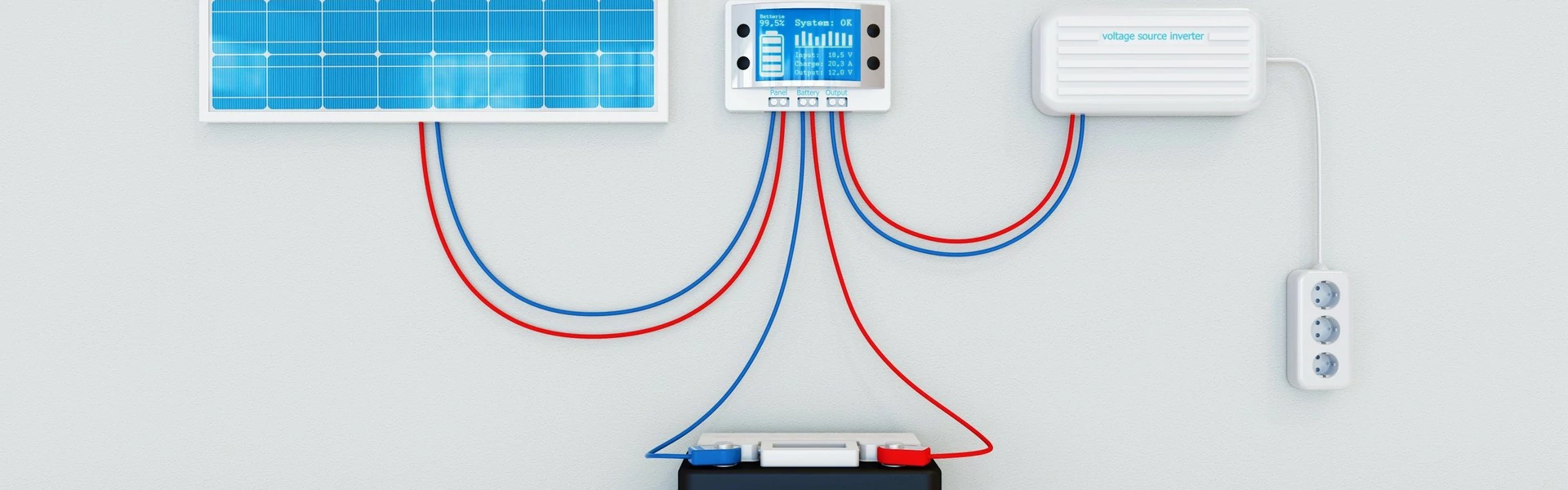

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

Photovoltaic controller

Photovoltaic controller Photovoltaic controller is the key equipment used to...

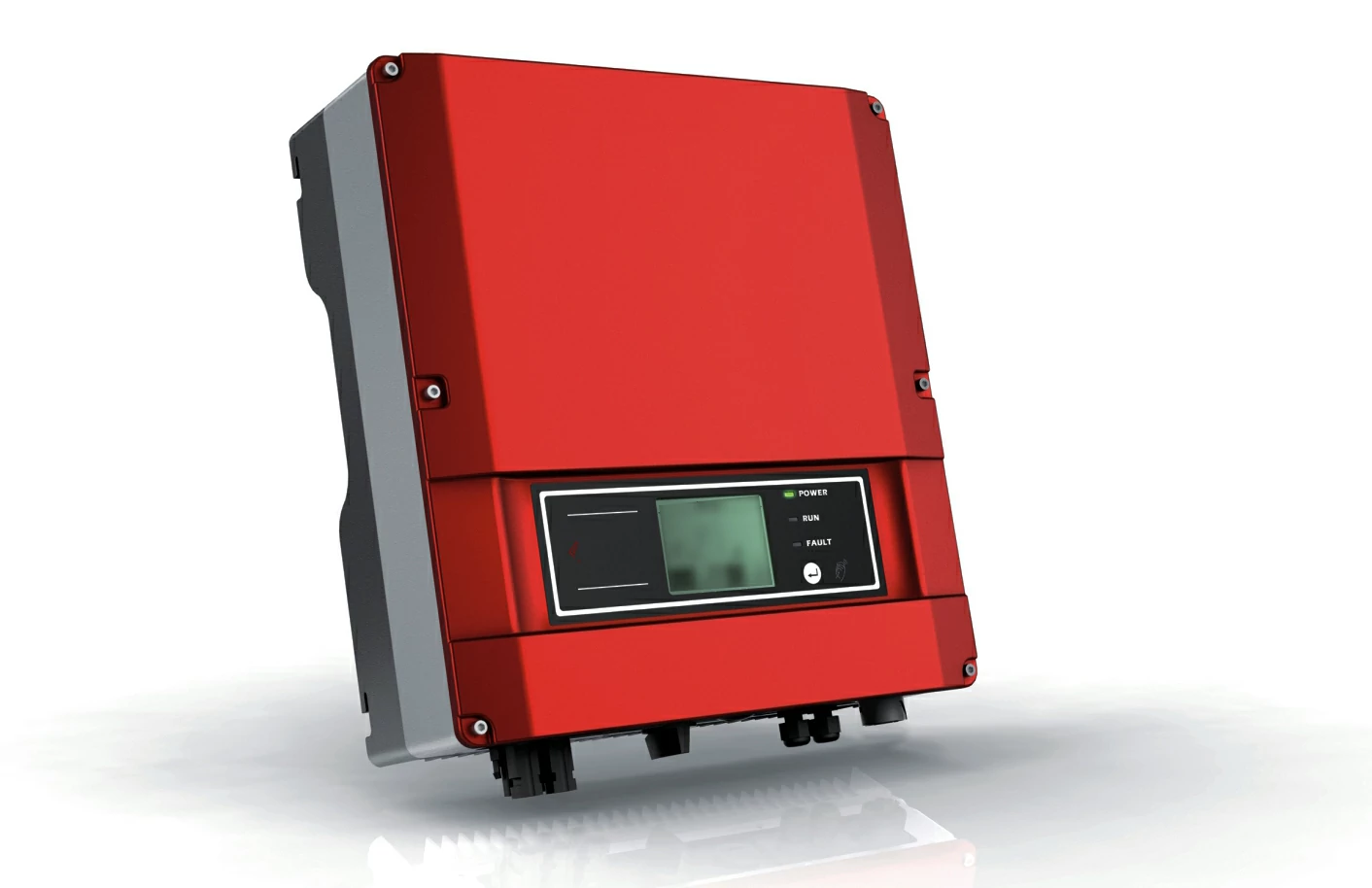

Photovoltaic inverter

Photovoltaic inverter Generally, the process of converting AC electrical energy...

Smart home energy storage battery

A highly integrated backup power solution for solar home energy...

Photovoltaic connector

Photovoltaic connector With the rapid development of global renewable energy,...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.