Photovoltaic connector With the rapid development of global renewable energy,...

The production and generation process of photovoltaic modules

manufacture

Component manufacturing process After the battery separation - single welding - series welding - splicing (that is, the series welded battery positioning, splicing together)- intermediate test (intermediate test: infrared test and appearance inspection)- lamination - trimming - after layer appearance - after layer infrared - framing (generally aluminum frame)- installation of junction box - cleaning - testing (this link also includes external testing and appearance inspection. Determine the level of the component)- packaging.

(1) Battery test

Due to the randomness of the production conditions of the battery, the performance of the produced battery is not the same, so in order to effectively combine the performance of the same or similar batteries together, it should be classified according to its performance parameters; Battery testing classifies batteries by testing their output parameters (current and voltage). To improve the utilization rate of the battery, make qualified battery components.

(2) Front welding

The bus strip is welded to the main grid line on the front side (negative electrode) of the battery. The bus strip is a tin-plated copper strip. The welding machine we use can spot weld the welding strip on the main grid line in the form of multiple points. The heat source for welding is an infrared lamp (using the thermal effect of infrared). The length of the welding tape is about twice the length of the side of the battery. The extra welding tape is connected to the back electrode of the rear battery when welded on the back.

(3) Back series connection

Back welding is to string batteries together to form a string of components. The process we currently adopt is manual. The positioning of the battery mainly depends on a film plate with a groove for placing the battery. The size of the groove corresponds to the size of the battery. The operator uses a soldering iron and a soldering wire to weld the front electrode (negative) of the "front battery" to the back electrode (positive) of the "back battery", which in turn are connected together and welded to the positive and negative leads of the component string.

(4) laminated laying

After the back side is connected and passed the inspection, lay the component string, glass, cut EVA, glass fiber, and backplane in a certain level and prepare for lamination. The glass is coated with a primer to increase the bonding strength of the glass and EVA. When laying, ensure the relative position of battery string and glass and other materials, adjust the distance between batteries, and lay a good foundation for lamination. (Laying level: from bottom to top: tempered glass, EVA, battery, EVA, glass fiber, backplane).

(5) Component lamination

The laid battery is placed in the laminator, the air in the component is extracted by vacuuming, and then the EVA is heated to melt the battery, the glass and the backplane together; Finally cool the components out. The lamination process is a key step in component production, and the lamination temperature and lamination time are determined by the nature of EVA. When we use fast curing EVA, the lamination cycle time is about 25 minutes. The curing temperature is 150℃.

(6) Trimming

During laminating, EVA extends outward and solidifies to form rough edges due to pressure after melting, so it should be cut off after laminating.

(7) Mounting frame

Similar to putting a frame on glass; The aluminum frame is installed on the glass component to increase the strength of the component, further seal the battery component, and extend the service life of the battery. The gaps in the frame and glass assembly are filled with silicone resin. Each border is connected by Angle keys.

(8) Weld the junction box

Solder a box to the back lead of the assembly to facilitate the connection between the battery and other devices or batteries.

(9) High voltage test

High voltage testing refers to applying a certain voltage between the component frame and the electrode lead to test the voltage resistance and insulation strength of the component to ensure that the component is not damaged under harsh natural conditions (lightning strikes, etc.).

(10) Component testing

The purpose of the test is to calibrate the output power of the battery, test its output characteristics, and determine the quality level of the component. At present, it is mainly to simulate the test Standard test condition (STC) of sunlight, and generally the test time required for a panel is about 7-8 seconds.

Production process

Single piece welding: weld the interconnection strip (coated with tin copper strip) of the battery to prepare for the series of the battery.

Series welding: the battery pieces are connected in series according to a certain number.

Lamination: the battery string is continued to connect the circuit, and the battery sheet is protected with glass, EVA film and TPT backplane.

Lamination: the battery and glass, EVA film, TPT backplane in a certain temperature, pressure and vacuum conditions bonded together.

Frame: Use aluminum frame to protect the glass, while easy to install.

Cleaning: Ensure the appearance of the components.

Electrical performance test: Test the insulation performance and power generation of the components

Finally pack and put into storage.

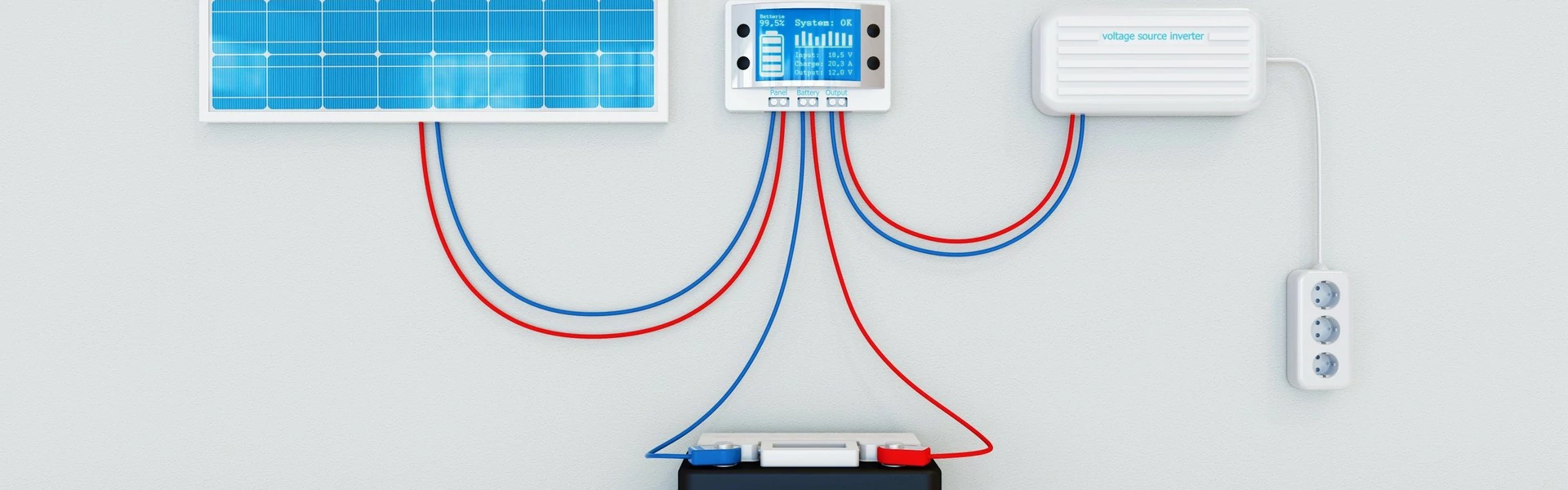

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

Smart home energy storage battery

A highly integrated backup power solution for solar home energy...

Photovoltaic controller

Photovoltaic controller Photovoltaic controller is the key equipment used to...

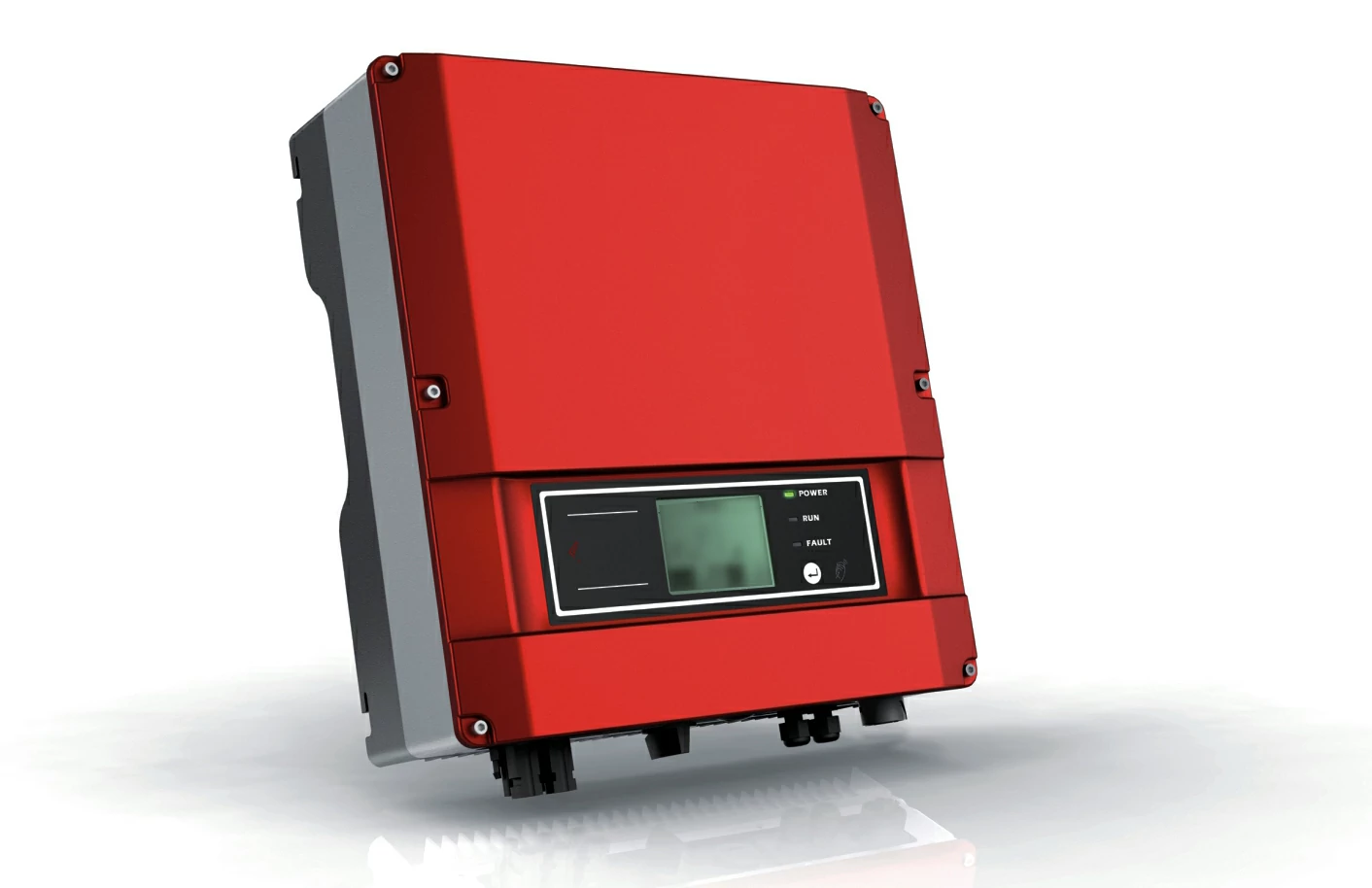

Photovoltaic inverter

Photovoltaic inverter Generally, the process of converting AC electrical energy...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.