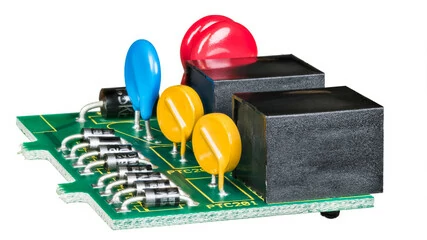

EPS inverter protection circuit analysis – overvoltage, overcurrent protection Emergency...

polypropylene (PP) 2

In the EPS (Encapsulated Power System) battery cell, safety valves and pressure relief devices are key components to prevent excessive pressure inside the battery. Polypropylene (PP), as a thermoplastic with good chemical stability and handling properties, is increasingly used in the manufacturing of these safety components. The manufacturing process and design considerations for polypropylene in EPS cell safety valves and pressure relief devices are described in detail below.

main content

Manufacturing process

In the manufacturing process of polypropylene safety valves and pressure relief devices, the following processes are generally involved:

Injection molding: The polypropylene particles are heated and melted by an injection molding machine and injected into the mold to form. This method is suitable for mass production and ensures dimensional accuracy and shape uniformity.

Machining: Machining is performed on the molded product to achieve higher precision and surface quality. This can include processes such as drilling, cutting and polishing.

Surface treatment: The surface of polypropylene can be coated or treated to enhance its aging resistance and appearance, and improve the overall use effect.

Design considerations

When designing polypropylene safety valves and pressure relief devices, the following factors need to be considered:

Opening pressure setting: The opening pressure of the safety valve must be accurately calculated to ensure timely release if the internal pressure exceeds the safety threshold.

Valve design: The shape of the valve and the design of the interrelated components need to be effectively sealed and have good pressure resistance.

Temperature resistance: Considering the operating temperature range of the battery, choose a polypropylene material suitable for the temperature range.

Environmental adaptability: In some extreme use environments, the chemical resistance and high temperature resistance of polypropylene must be tested and verified.

CONCLUSION

Due to its excellent chemical stability, light weight, high strength and multi-functional molding characteristics, polypropylene has become an important material for EPS cell safety valve and pressure release device. With the growth of battery demand, polypropylene will be more widely used in safety valve design, and its excellent cost performance will also promote the battery manufacturing industry to a more efficient and safer direction.

EPS BATTERY SERIES

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

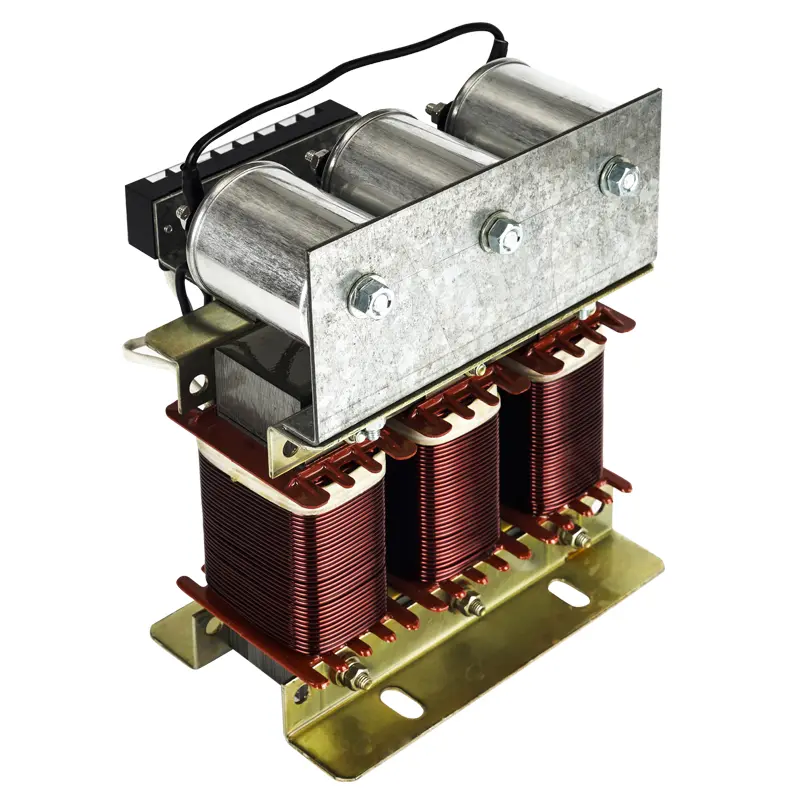

EPS inverter output filter analysis

EPS inverter output filter analysis In the emergency power supply...

Materials for safety valves and pressure relief devices – stainless steel

Materials for safety valves and pressure relief devices – stainless...

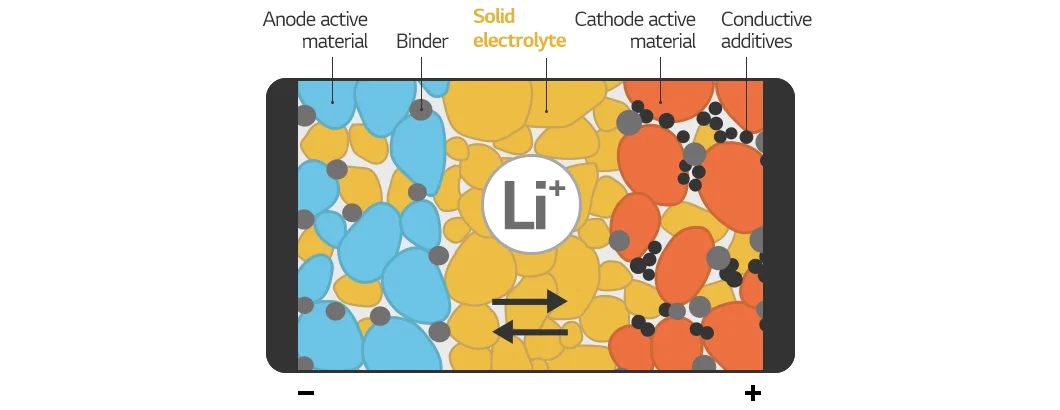

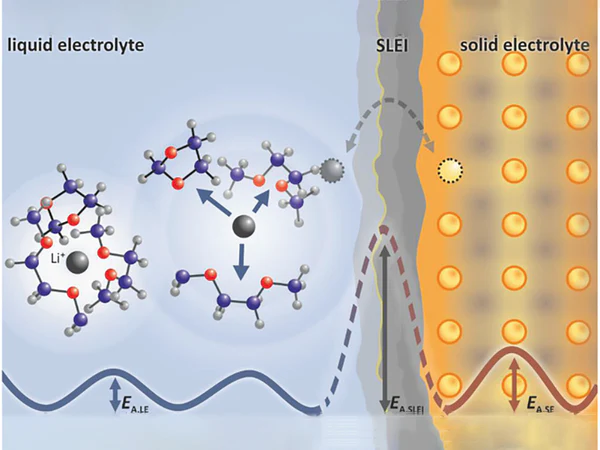

Introduction to electrolytes of EPS battery cells

electrolytes of EPS battery cells In the EPS cell, the...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.