Safety valve and pressure release device of EPS battery unit...

Isolation film material of EPS cell monomer: polymer

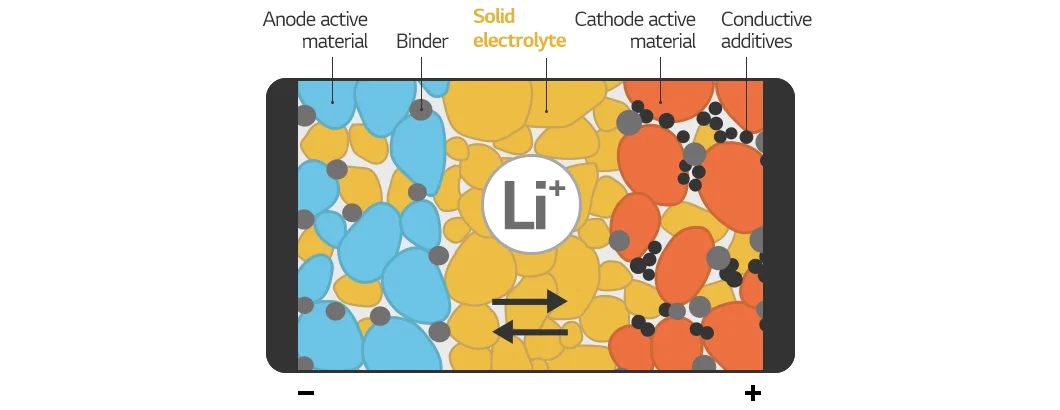

In the EPS battery cell, the isolation membrane is one of the key components, its main role is to separate the positive and negative electrodes of the battery to prevent short circuit, while allowing lithium ions to pass through to complete the charge and discharge process. The application of polymer materials in isolation membranes has received much attention because of its unique properties. The following is the introduction of several polymer material isolation membranes:

PVDF (polyvinylidene fluoride) diaphragm

PVDF diaphragms have been extensively studied for their excellent mechanical properties and chemical resistance. The PVDF membrane exhibits a porous microstructure with a porosity of 20% and a pore size of less than 1 micron. This diaphragm not only has good mechanical properties, but also performs well in terms of battery cycle performance and rate performance. PVDF copolymer diaphragms, such as PVDF-HFP, PVDF-TRFE, and PVDF-CTFE, have also been studied, with PVDF-TRFE diaphragms showing the best cell performance due to their high porosity and strong electrolyte affinity.

Polyolefin separator

Polyolefin diaphragms, including polyethylene (PE) and polypropylene (PP) and their composite membranes, are commonly used as diaphragm materials in lithium-ion batteries. This kind of diaphragm has good mechanical properties and cost effectiveness. In order to improve its ionic conductivity and mechanical properties, the researchers synthesized PMMA-VAc polymer by emulsion polymerization and coated it on PE film. The resulting polymer film has excellent cross-linked network microporous structure and high liquid absorption rate.

Polyimide (PI) diaphragm

PI diaphragms are known for their excellent thermal stability. By coating PE particles on the surface of PI film, the prepared PI-PE composite film not only has excellent thermal closed cell effect, but also improves the infiltration and lithium ion conductivity of the electrolyte.

Non-woven polymer diaphragm

Non-woven membranes have attracted attention because of their high porosity. The UV radiation crosslinking of polyethylene glycol diacrylate (PEGDA), polyvinylidene fluoride (PVDF) and polymethyl methacrylate (PMMA) showed high mechanical strength and good ionic conductivity.

Polymer-ceramic composite diaphragm

In order to improve the thermal stability and electrolyte wettability of polyolefin membranes, polymer-ceramic composite membranes were developed. This diaphragm combines the flexibility of organic polyolefin with the high temperature resistance of inorganic ceramic particles to improve the safety of the battery.

New material system

In addition to the above materials, there are fluoropolymer diaphragms, cellulose diaphragms, polyester (PET) diaphragms and other new material systems. These materials are used in the development of battery separators because of their respective advantages, such as high thermal stability, lyophilicity, and abundant resources.

CONCLUSION

To sum up, polymer materials are widely used in the isolation film of EPS cell monomer, and different polymer materials are suitable for different application scenarios due to their unique properties. With advances in materials science, the development of new polymer diaphragms will continue to drive battery technology.

EPS BATTERY SERIES

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

What are the specific advantages of transformerless inverters in fire fighting systems?

What are the specific advantages of transformerless inverters in fire...

EPS inverter inverter circuit details – switching components

EPS inverter inverter circuit details – switching components Fire Emergency...

Detailed explanation of EPS AC charging interface

Detailed explanation of EPS AC charging interface In the emergency...

Control system analysis – control algorithm

Control system analysis – control algorithm The control algorithm is...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.