Product testing Product testing is a key link to ensure...

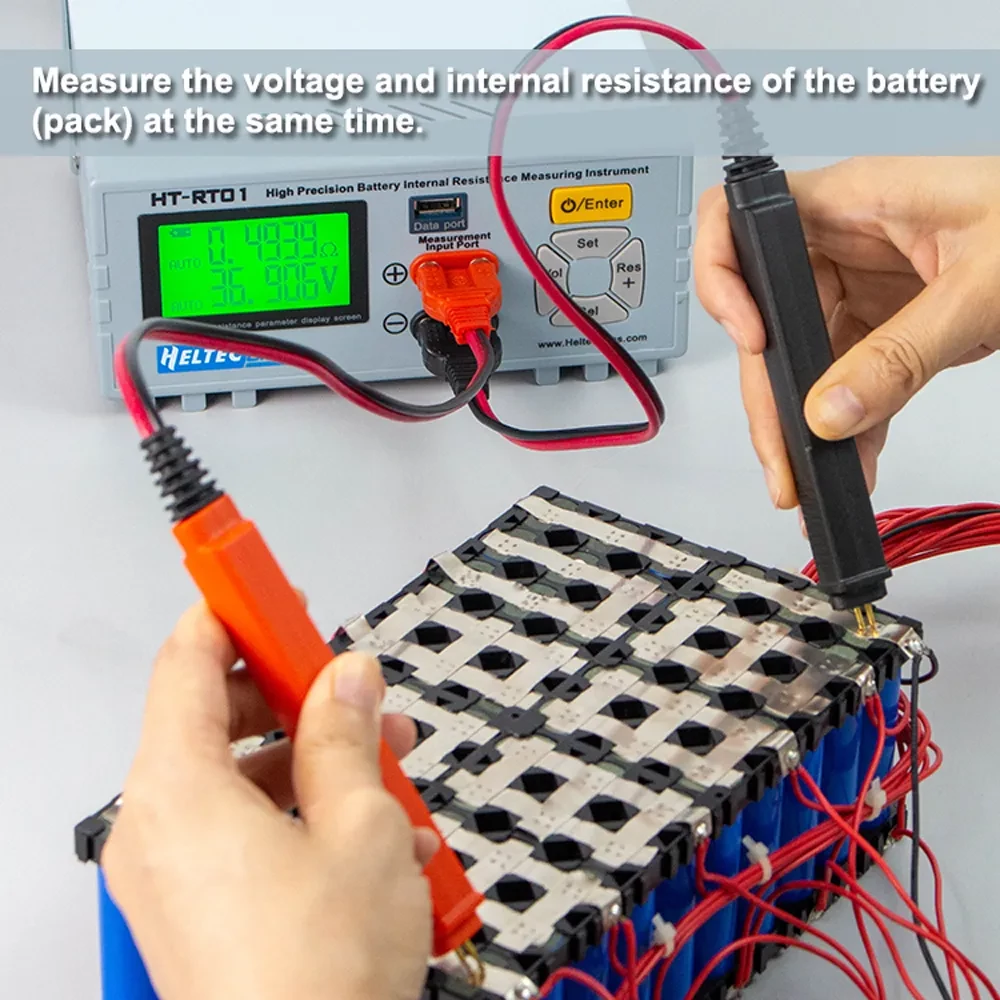

Internal resistance test

The Internal Resistance test is one of the important indicators to evaluate the performance of the battery. Internal resistance (IR) is the obstruction of the current flow inside the battery, which affects the efficiency, power output and heat generation of the battery. The greater the internal resistance, the battery will generate more heat when discharging, the discharge efficiency is lower, and may cause the battery to overheat and shorten the service life. Therefore, the internal resistance test is essential to ensure the performance, safety and long life of the battery.

Internal resistance test

The internal resistance test is a key step in the battery performance evaluation, which can help judge the efficiency, safety and service life of the battery. By regularly detecting changes in the internal resistance of the battery, potential problems can be detected in time to optimize the design and use of the battery. Especially in applications with high power requirements, the control of internal resistance is particularly important to ensure that the battery can run stably under high loads.

Basic principles and procedures

The Open Circuit Voltage (OCV)

Method calculates the internal resistance of a battery by measuring the open circuit voltage at static state and the change of current during discharge. This method is relatively simple, but may not be precise enough because it assumes that the voltage of the battery when it is open represents its true voltage.

AC Impedance Measurement

This measures the impedance of the battery (i.e. the resistance of the battery to alternating current) by applying a small amplitude AC signal (usually in the frequency range of 1kHz to 100kHz). This method is more complex, but provides more accurate internal resistance data and can distinguish between different types of impedance inside the battery.

The DC Method

Directly calculates the internal resistance of the battery by measuring the relationship between the voltage change at both ends of the battery and the current during discharge or charging. Usually during the battery discharge process, the battery voltage and current change is more obvious, which is suitable for measuring the DC internal resistance of the battery.

HF Impedance method

This method evaluates the electrochemical characteristics and internal resistance of the battery by measuring its response to high-frequency AC signals. This method is commonly used for high-precision battery testing.

low-speed car batteries

Low-speed vehicle battery is a kind of battery designed for low-speed electric vehicles, which has the characteristics of clean, environmental protection, high efficiency and economy, and is widely used in electric golf carts, low-speed electric vehicles (LSV), mobile vendors, campus transportation, cargo trucks and so on

Extended reading

Product packaging and delivery

Product packaging and delivery The packaging and delivery of battery...

Product information expansion

Product information expansion Understanding low-speed vehicle battery product information is...

Product composition

Low-speed lithium battery product composition Understanding the product composition of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.