Serial communication interface of DC charging pile microcontroller: bridge of...

The soft start circuit of DC charging pile power switch chip is introduced

Main component

Concept:

The soft start circuit is an important part of the DC charging pile power switch chip, its main function is to gradually increase the output voltage when the power supply starts, in order to avoid the damage to the power module or the load due to the instantaneous high current. This circuit design helps to reduce the surge current at startup, protect the power module, and extend its service life.

Function:

The main functions of the soft start circuit include:

1. Reduce surge current: Prevent excessive surge current when the power supply is started, protect the power module and load.

2. Smooth start: the output voltage is gradually increased at a controlled rate to avoid voltage overshoot and voltage drop.

3. Improve system stability: By controlling the current and voltage during startup, improve the stability and reliability of the entire power system.

Working Principle:

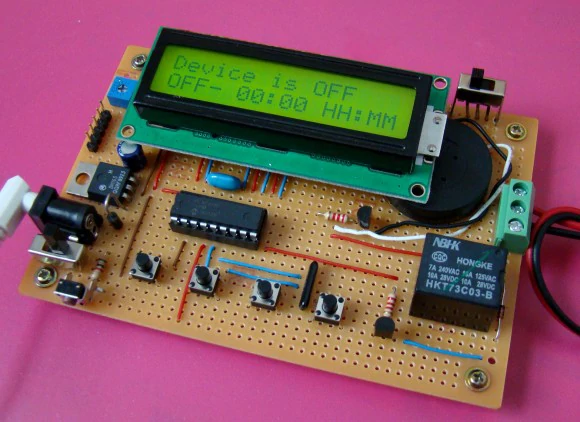

1. Controller and detection points: The soft start circuit includes a controller that collects measurements from multiple detection points in real time and obtains information about battery pack charging voltage and current from the vehicle battery management system (BMS).

2. Rectifier module and switch: The circuit includes a rectifier module, a first switch, a second switch and an anti-backdown diode. The positive and negative output terminals of the rectifier module are electrically connected with the controller, and the controller avoids the generation of surge current by adjusting the output voltage and current of the rectifier module, and controlling the on-off sequence of the first switch and the second switch.

3. Soft boot process: The soft boot process includes the following steps:

Step 1: The controller monitors voltage and current, sets the rectifier module output voltage target value to zero, the output current limit to zero, and then starts the rectifier module output.

Step 2: The rectifier module output voltage target value rises at the normal rate.

Step 3: When the voltage is detected to reach the target value, the controller keeps the voltage target value unchanged and controls the first switch and the second switch to close.

Step 4: After detecting that the switch is closed, increase the output voltage of the rectifier module and control the output current limit of the rectifier module.

Step 5: When the current value reaches a certain limit, increase the rectifier module output current limit until the charging current requested by the BMS is reached.

Step 6: The target voltage of the rectifier module is increased to the maximum allowable charging voltage of the battery pack requested by the BMS, the soft start charging process is completed, and the normal charging process is entered.

4. Soft start time: The soft start time (Tss) can be set by internal or external soft start capacitors (Css), the general principle of soft start is to use a constant pul-up current (Iss) to charge the internal or external soft start capacitors in order to adjust the capacitor voltage (Vss) slope with the design slope.

5. The realization of soft start circuit: the realization of soft start function usually has two methods: internal soft start and external soft start. An internal soft start is usually charged by a current source inside the chip, while an external soft start requires a soft start capacitor to be connected outside the chip.

Sum up

Through the above principles and steps, the soft start circuit of the DC charging pile power switch chip can effectively control the current and voltage during the start process to ensure the stability and safety of the charging process.

DC CHARGING PIlE SERIES

DC charging pile is an efficient charging facility for electric vehicles, which uses direct current (DC) to directly charge the vehicle battery, significantly reducing the charging time. Compared with traditional AC charging piles, DC charging piles are able to provide higher power output and can usually charge an EV to 80% of its capacity in 30 minutes, providing users with a convenient charging experience.

Extended reading

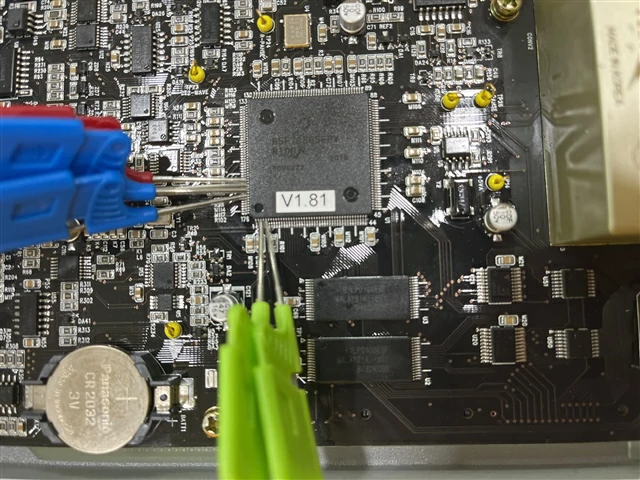

The timer of the DC charging pile microcontroller: the core of precise control

The timer of the DC charging pile microcontroller: the core...

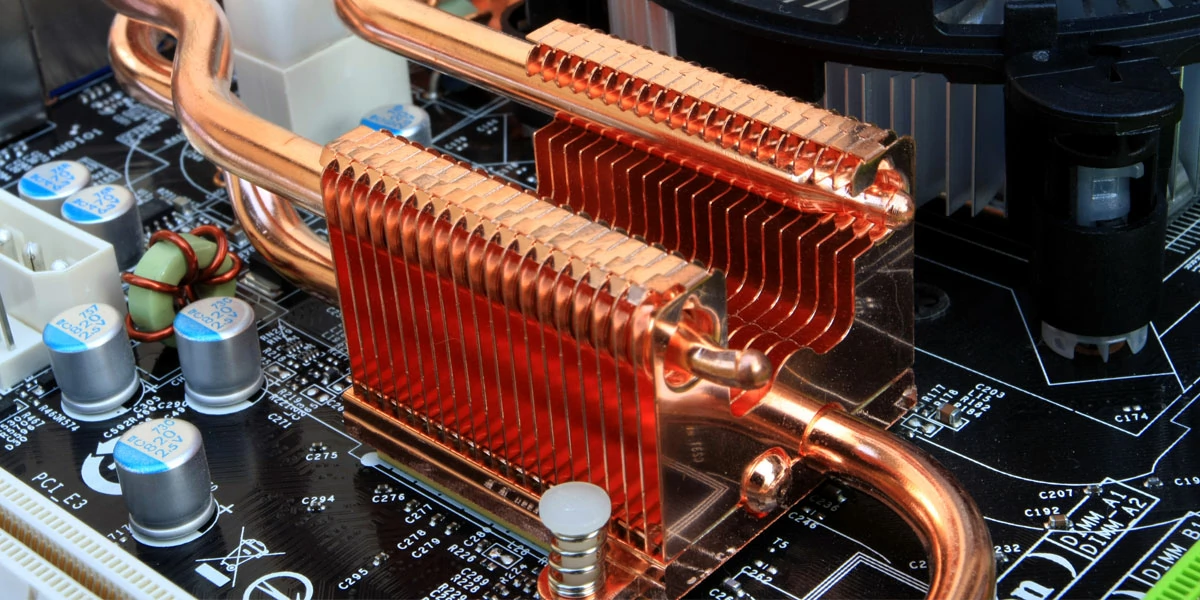

Introduction of heat pipe in DC charging heat dissipation system

Introduction of heat pipe in DC charging heat dissipation system...

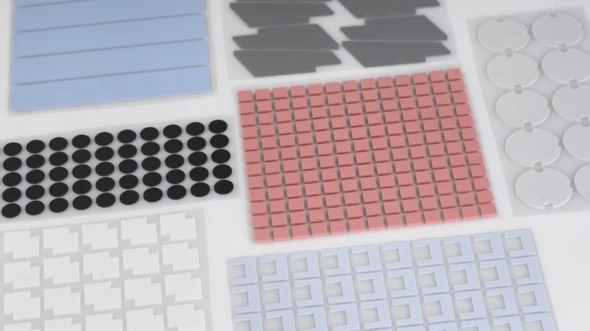

About the heat dissipation materials in the indicator

An introduction to the insulation materials in the indicator light...

What are grounding contact made of?

What are grounding contact made of? Grounding contacts are typically...

Product overview of DC charging pile

A highly integrated backup power solution for solar home energy...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.