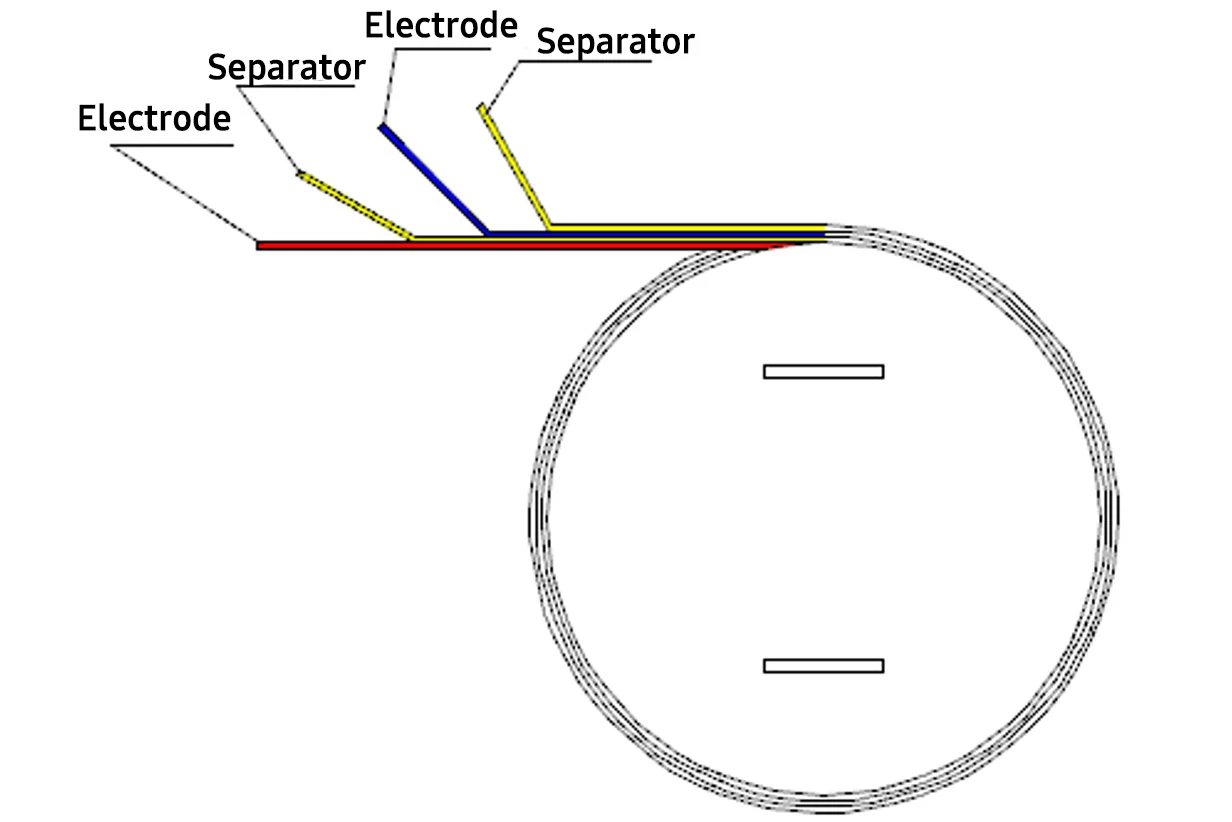

Process of winding After laser cutting the pole piece, through...

battery module process

The battery module is a complete battery system unit composed of multiple battery units (battery cells). It is an important component in battery energy storage systems, hybrid electric vehicles (HEVs), pure electric vehicles (EVs), and renewable energy systems such as solar and wind. Battery modules are designed to improve the overall performance, capacity, and stability of the battery while simplifying the management and connectivity of the entire battery system.

process

Battery Cell Loading: Placing cells on the production line.

Battery Cell Scanning: The battery cell is scanned to confirm its information.

Battery Cell OCV/ACIR Testing (OCV/ACIR testing) : Performs an open-circuit voltage /AC internal resistance test on a battery cell.

Battery Cell Insulation Testing

Pole ear leveling, cutting, length detection

Battery Cell Adhesive Spraying/Drying

Foam Loading/Adhesive Spraying/Drying

Battery Cell Stacking: Batteries are stacked to form modules.

Stack detection

Stacking and Pressing: Stacking and pressing modules.

Module Loading into Fixture

Module Applying Thermal Conductive Adhesive

U-Shell Loading and Coding: The U-shell is placed on the production line and coded.

Module into the shell

Installing Tab Bracket

Tab Bending and Flattening: The TAB bending and flattening of the pole ear.

Tab Welding: The electrode is welded.

Tab Welding Quality Inspection

Insulation Withstand Voltage Testing: Test the insulation withstand voltage performance of the module.

Installing Insulation Cover

Installing Sampling Wires and Terminals Installing sampling wires and terminals

Welding Sampling Terminals: Welding the sampling terminals.

Terminal Welding Quality Inspection

Installing End Plate Components: Install the end plate components of the module.

Installing Temperature Sensor and Thermal Conductive Adhesive

Installing Aluminum Top Cover

Housing Welding Quality Inspection: Checks the quality of housing welding quality.

Module Laser Coding

Module End of Line Testing : The final test of the module is performed.

Module Size and Weight Inspection

Module Labeling

Module Unloading: Removes a finished module from the production line.

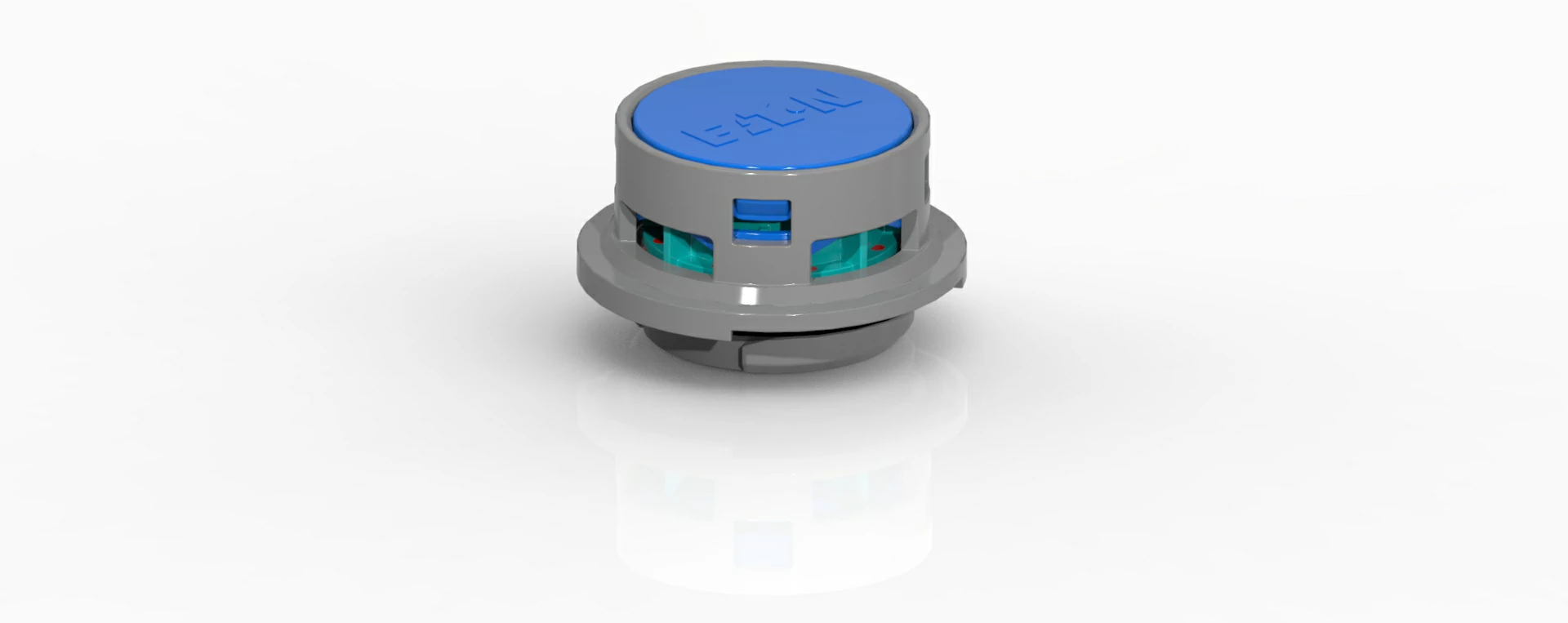

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

Introduction to the battery pack safety valve

Introduction to the battery pack safety valve Battery packs are...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.