Product testing Product testing is a key link to ensure...

Formation process

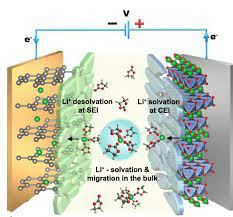

Formation is an important process that enables the battery to complete the initial charge and discharge cycle by controlling the charge and discharge conditions, thus activating its electrochemical reaction. The formation can not only improve the performance and stability of the battery, but also form a stable solid electrolyte interface film (SEI film) to protect the negative electrode material and extend the battery life.

Formation process

Formation is a crucial link in the manufacturing process of lithium batteries, and its main significance is to activate the electrochemical reaction of the battery through the initial charge and discharge to form a stable solid electrolyte interface film (SEI film), thereby improving the energy density, cycle life and stability of the battery. At the same time, the formation process also detects the initial performance of the battery, screens out unqualified batteries, ensures consistency and safety, and lays the foundation for subsequent capacity separation and assembly.

Main steps

Initial charging

Purpose: Activate the positive and negative electrode materials through the initial charge and allow the chemical reactions inside the battery to begin to stabilize.

Procedure:

The battery is slowly charged at a low current (e.g. 0.05C~0.2C), gradually rising to a set voltage (e.g. 3.6V or 4.2V).

This process helps the reaction between the electrode material and the electrolyte to be uniform, avoiding too fast a reaction that can cause damage to the battery.

Results: The electrolyte formed a protective film (SEI film) on the surface of the anode material, which provided a stable chemical environment for the subsequent cycle.

Constant current charging

Objective: To charge the battery in constant current mode and gradually increase the battery power.

Procedure:

At a set current (e.g. 1C or below), charge the battery at constant current until the battery voltage reaches the set upper limit (e.g. 4.2V).

This process is mainly to improve the degree of activation of the battery, so that the internal reaction of the battery is more adequate.

Note: This stage requires strict control of the current to avoid overheating or uneven reaction of the battery.

Constant voltage charging

Purpose: To ensure that the chemical reaction inside the battery is complete and to allow for more uniform charging.

Procedure:

When the battery voltage reaches the set value (such as 4.2V), switch to the constant voltage mode to charge, maintain a constant voltage, and the current gradually decreases to the set cutoff current (such as 0.05C).

Constant voltage charging allows the electrolyte to fully infiltrate the electrode material and further stabilize the internal environment of the battery.

Results: The electrochemical performance of the battery was stable.

Initial discharge

Objective: To test the initial capacity and performance of the battery by discharge, and to further stabilize the SEI film.

Procedure:

Use constant current mode discharge to lower the battery voltage from full charge (e.g. 4.2V) to a set cut-off voltage (e.g. 2.5V or 3.0V).

During this process, the battery releases stored energy and tests its capacity, internal resistance and discharge performance.

Results: The first cycle was completed and the preliminary performance parameters of the battery were recorded.

low-speed car batteries

Low-speed vehicle battery is a kind of battery designed for low-speed electric vehicles, which has the characteristics of clean, environmental protection, high efficiency and economy, and is widely used in electric golf carts, low-speed electric vehicles (LSV), mobile vendors, campus transportation, cargo trucks and so on

Extended reading

Product packaging and delivery

Product packaging and delivery The packaging and delivery of battery...

Product information expansion

Product information expansion Understanding low-speed vehicle battery product information is...

Product composition

Low-speed lithium battery product composition Understanding the product composition of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.