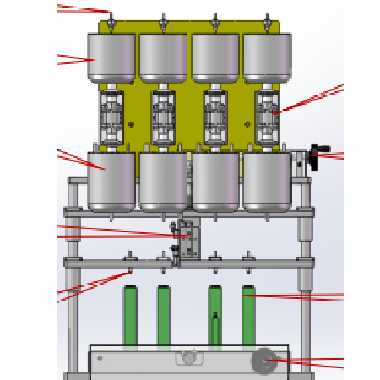

Production process 9- liquid injection In the UPS (uninterruptible power...

Production process 12- Capacity test

In the UPS (uninterruptible power supply) production process, the capacitance test is a key step in forming the battery module to ensure that the performance of the battery module meets the standard requirements of the UPS. The following is the main process and key points of the volume detection:

main content

The basic principle

Based on the charging and discharging characteristics of the battery, the capacitance and internal resistance of the battery can be calculated by controlling the charging and discharging process and measuring the battery voltage, current and other parameters.

The role and importance of volume separation

Ensure product consistency and reliability: Fractional volume testing can screen out batteries with stable performance and reliable quality, so that the final product has high consistency and reliability.

Extended battery cycle life: Removing bad batteries can improve the cycle life of the overall battery pack and reduce the overall performance degradation caused by individual battery problems.

Increase battery energy density: Combining batteries with similar capacities can maximize the energy density of the battery pack to meet the energy requirements of different application scenarios.

Key steps

Formation treatment: The formation treatment of the newly produced battery, including small current charge and discharge, static temperature and other steps, so that the chemical substances inside the battery fully react to achieve a stable state.

Capacity test: The standard charging and discharging process is used to measure the capacity of the battery under different conditions and obtain accurate capacity data.

Data analysis and screening: With the help of professional software system, the test data is analyzed and processed, and the batteries that meet the requirements are screened according to the set standards.

Grouping assembly: According to the battery capacity, internal resistance and other parameters, it is classified into battery packs to ensure that the battery performance in each battery pack is similar.

Quality inspection: Comprehensive quality inspection of the assembled battery pack, including appearance inspection, performance testing, etc., to ensure that the product meets the relevant standards.

Charge and discharge test

Charging test: Connect the battery and test equipment, charge according to the set charging current and time, observe the charging current, voltage, time and other parameters in the test process, and evaluate the battery charging efficiency, charging speed, charging capacity and other indicators.

Discharge test: When the battery capacity reaches 100%, the discharge test begins. Discharge according to the set discharge current, and then observe the discharge current, voltage and time and other parameters, analyze the battery discharge capacity, discharge time and voltage stability and other indicators to determine whether the battery meets the design requirements.

Technical challenges

Technical challenges include the precise control of parameters such as temperature, current and ambient humidity, as well as the control of SEI film formation, which directly affect the electrochemical performance of the battery such as cycle life, stability, self-discharge and safety.

CONCLUSION

Through the above capacity testing process, you can ensure that the formed battery module has consistent performance and reliability, and meets the UPS standard requirements for battery performance.

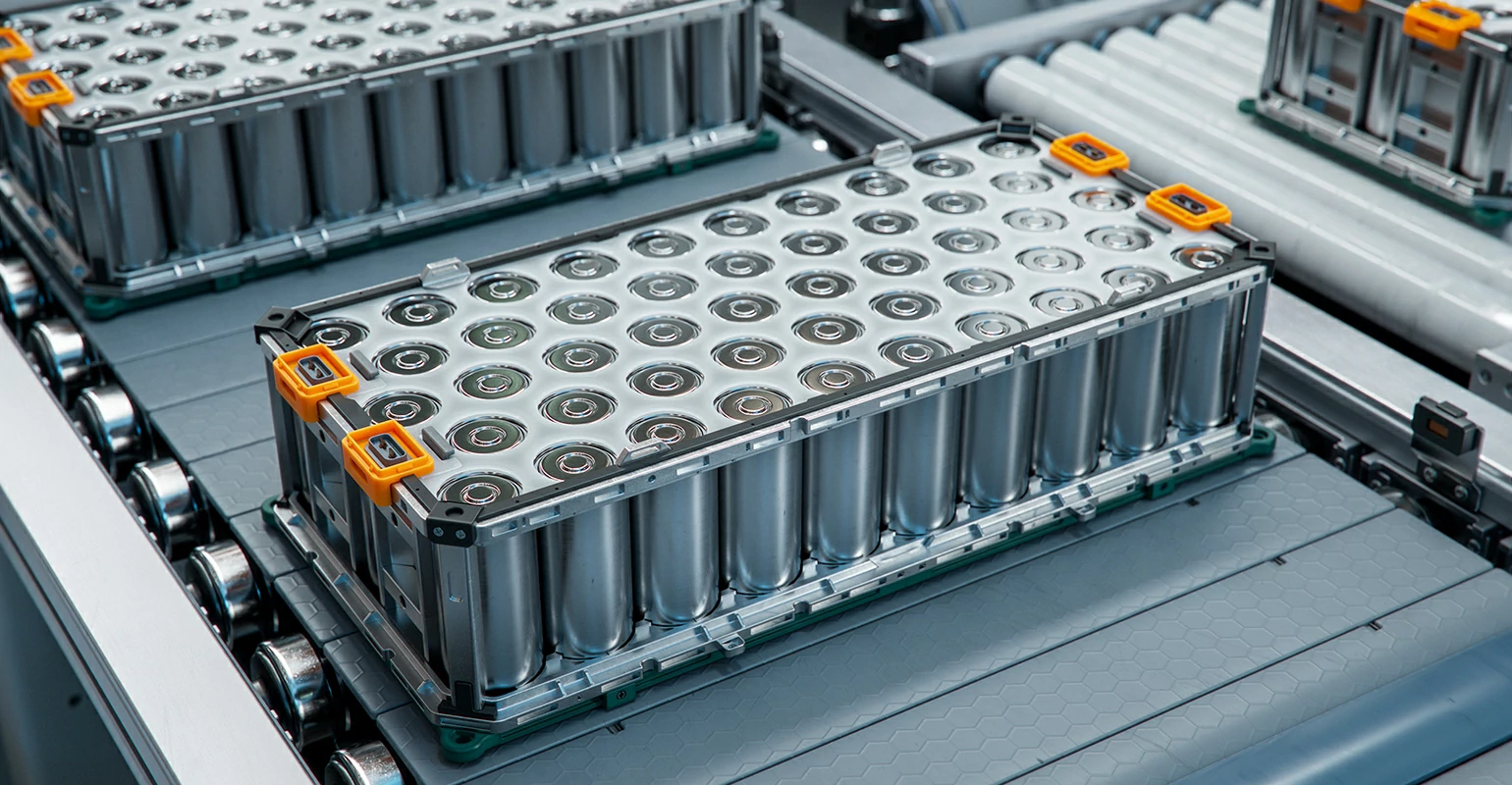

UPS BATTERY SERIES

UPS (Uninterruptible Power Supply) batteries are an important component of power supply systems designed to provide stable power support for electronic devices.

Extended reading

What are the pre-processing steps for the battery module before and after the capacitance test?

What are the pre-processing steps for the battery module before...

Production Process 2- Coating

Production Process 2- Coating Uninterruptible Power Supply (UPS) is an...

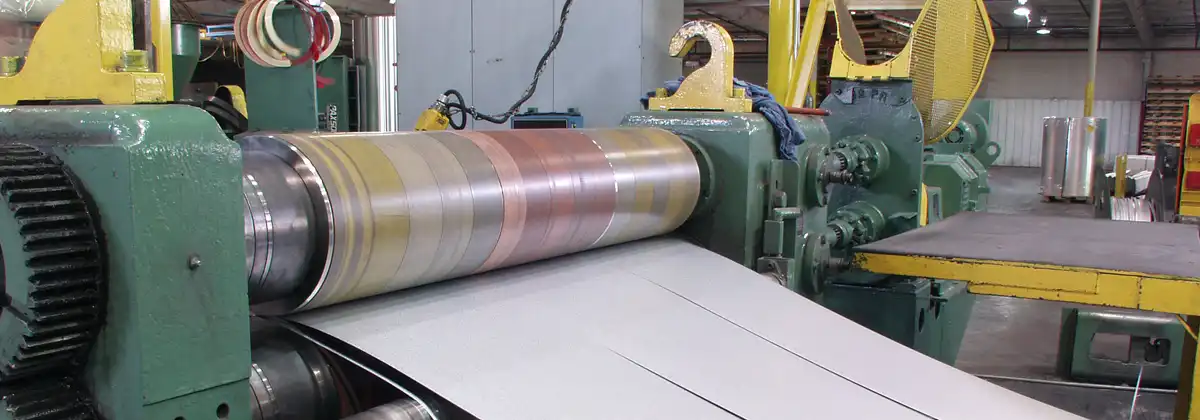

Production process 4-Cutting and slitting

Production process 4-Cutting and slitting Uninterruptible Power Supply (UPS) is...

Impact of deviation correction accuracy on battery performance

Impact of deviation correction accuracy on battery performance The impact...

Production process 7- Packaging

Production process 7- Packaging In the UPS (uninterruptible power supply)...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.