Charging and discharging efficiency test of single battery The charging...

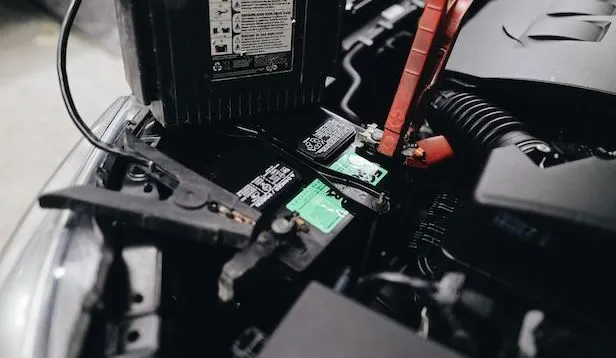

Product testing of finished battery pack

With the increasing demand for battery technology, especially in the field of electric vehicles, renewable energy storage systems, and high-performance electronic devices, the quality and performance testing of finished battery packs has become particularly important. The finished products of battery pack include positive electrode material, negative electrode material, electrolyte, diaphragm and shell, etc. Their performance testing is related to the overall performance, safety and life of the battery. This paper will deeply explore the product testing of battery pack finished products, including the main items, methods and standards of testing.

Main items of the test

Electrochemical performance test

Security testing

Physical and chemical property testing

Material purity: Analyze the chemical composition of positive and negative electrode materials, electrolyte and diaphragm to ensure that the material purity meets industry standards.

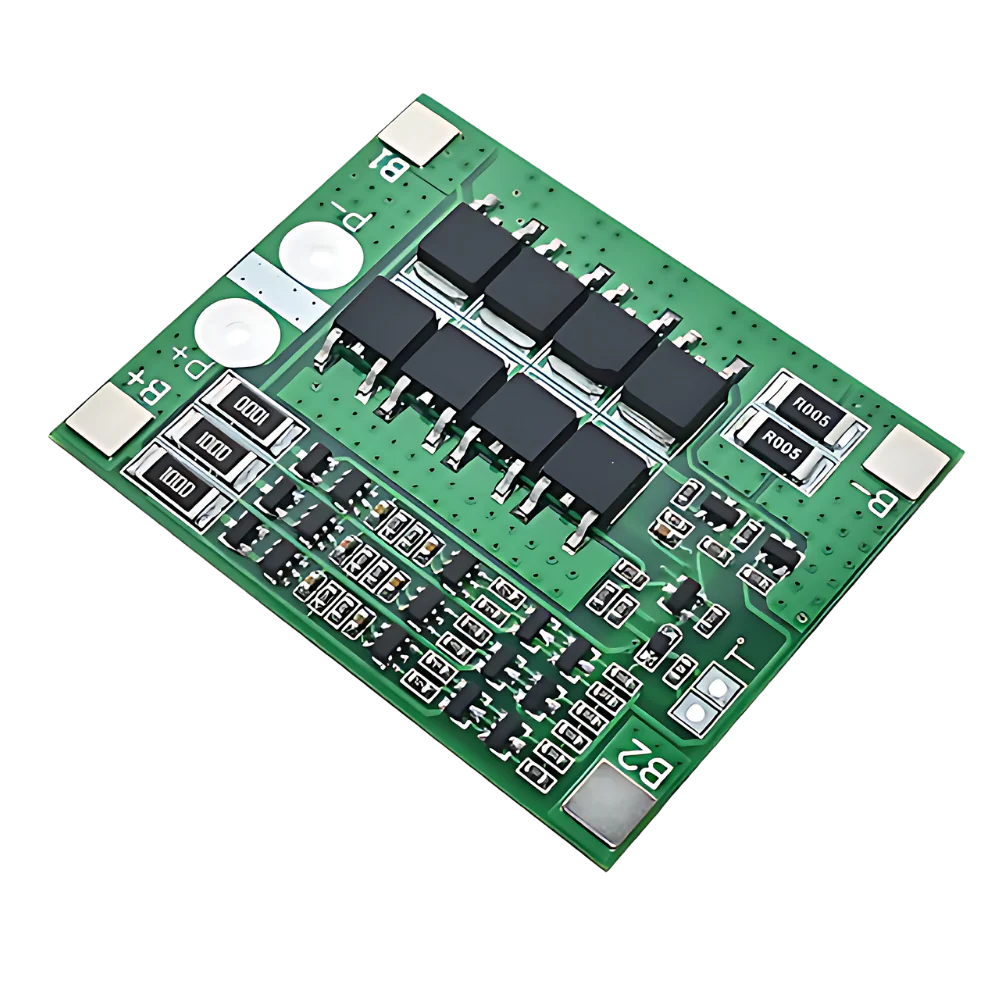

Test method

Laboratory testing

Electrochemical workstation: Use the electrochemical workstation to conduct static and dynamic electrochemical tests and obtain data such as charge and discharge curves and cycling performance of batteries.

Thermal analyzers: Devices such as differential scanning calorimeters (DSC) are used to analyze the thermal stability and phase transformation behavior of materials.

Simulation test

Computer simulation: Battery performance simulation software is used to predict and optimize the performance of the battery under different conditions of use.

Environmental simulator: The battery is tested in a controlled environment such as temperature and humidity to simulate the actual use.

Standardized testing

According to the International Electrotechnical Commission (IEC), American Society for Materials and Testing (ASTM), national battery standards and other standards, a systematic test process.

Test standards

The testing of finished battery packs should follow industry standards such as:

UL 2054: Evaluates the safety and performance of batteries.

UN 38.3: Standard for testing lithium batteries for transport to ensure safe transport.

IEC 62133: Defines safety and performance requirements for rechargeable batteries.

Conclusion

The product testing of finished battery pack is the key link to ensure the performance, safety and reliability of battery. Through comprehensive testing, not only can the design and production of batteries be optimized, but also can take the lead in the fierce market competition. With the continuous development of battery technology, testing methods and standards are also continuously updated and improved, promoting the healthy development of the battery industry. Therefore, enterprises should pay attention to the testing work of battery pack finished products to ensure that their products meet market demand and industry standards and enhance product competitiveness.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

Overview of the battery shell of the lithium iron phosphate monomer battery

Overview of the battery shell of the lithium iron phosphate...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.