Production process 10- Formation In the UPS (uninterruptible power supply)...

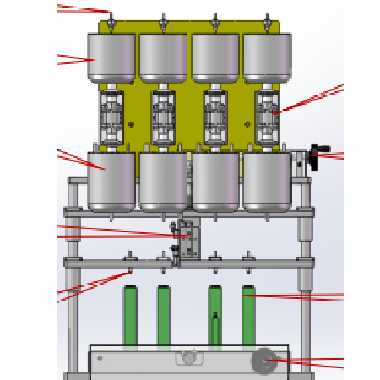

Production process 9- liquid injection

In the UPS (uninterruptible power supply) production process, liquid injection is a key step after the battery unit is baked to complete the battery activation process. The following are the main steps and key points of the liquid injection process:

main content

Preparation before injection

Before injection, the baked battery cell needs to be tested for humidity to ensure that it meets the baking standard before injection.

Vacuum environment establishment

Place the battery in a vacuum glove box, weigh it and record the weight. Then, the designed weight of the electrolyte is added to the injection cup. The injection chamber is vacuumed by the vacuum pump to form a vacuum environment inside the battery.

Electrolyte injection

The electrolyte is injected into the sealed chamber using a quantitative pump. The injection nozzle is inserted into the battery injection port, the electrolyte injection valve is opened, and the electrolyte chamber is pressurized with nitrogen to 0.2-1.0Mpa. After holding the pressure for a certain period of time, the injection chamber is then deflated to normal pressure.

Infiltration process

After the electrolyte is injected, the battery needs to sit for a long time (12-36 hours) to allow the electrolyte to fully infiltrate with the positive and negative battery materials and the diaphragm. This process is very time-consuming and greatly increases the production cost of lithium-ion batteries.

Electrolyte flow and penetration

In theory, the electrolyte will penetrate from the top of the battery into the diaphragm and electrodes, but in reality, a large amount of electrolyte flows down and accumulates at the bottom of the battery, and then permeates into the pores of the diaphragm and electrodes through capillary pressure.

Penetration rate of diaphragm and electrode

Generally, the diaphragm consists of a porous hydrophilic material with a large porosity, while the electrode consists of a porous medium composed of various particles. The electrolyte penetrates faster in the diaphragm than in the electrode, so the flow process of the electrolyte should first penetrate into the diaphragm and then penetrate through the diaphragm into the electrode.

Inspection and sealing after injection

After the liquid injection is completed, take out the battery piece and weigh it to calculate whether the injection amount conforms to the design value. If the amount of electrolyte is low, it needs to be replaced. If there are too many, just dump the excess until the design requirements are met. Finally, the battery is sealed to complete the liquid injection process.

Environmental requirements

During liquid injection, the ambient temperature and dew point of the glove box must be less than or equal to 23 ° C and -45 ° C.

CONCLUSION

Through the above injection process, the electrolyte inside the battery unit can be fully infiltrated, providing the necessary ion transport medium for the battery's charge and discharge, thereby activating the battery to ensure its performance and safety.

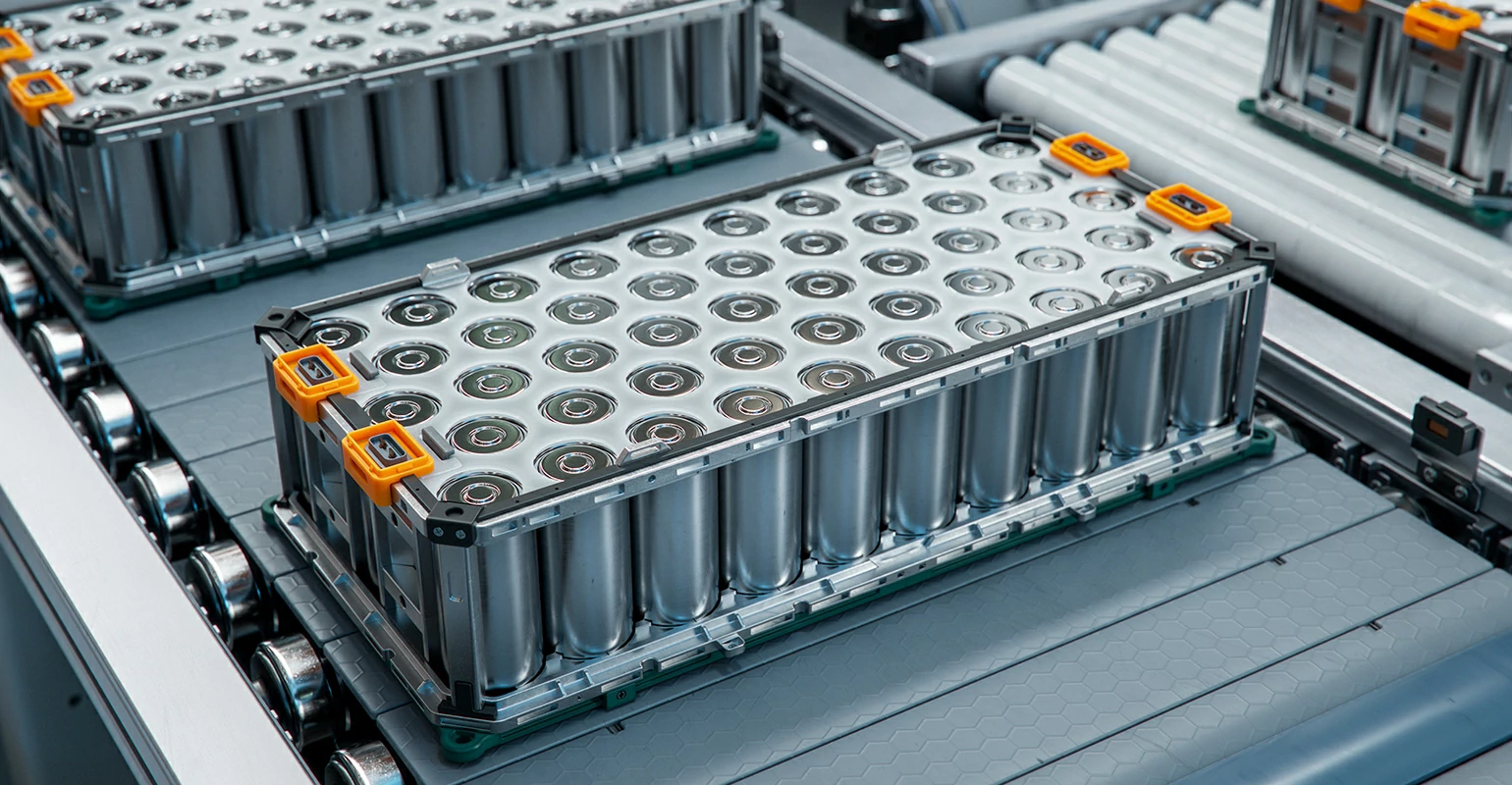

UPS BATTERY SERIES

UPS (Uninterruptible Power Supply) batteries are an important component of power supply systems designed to provide stable power support for electronic devices.

Extended reading

Production process 9- liquid injection

Production process 9- liquid injection In the UPS (uninterruptible power...

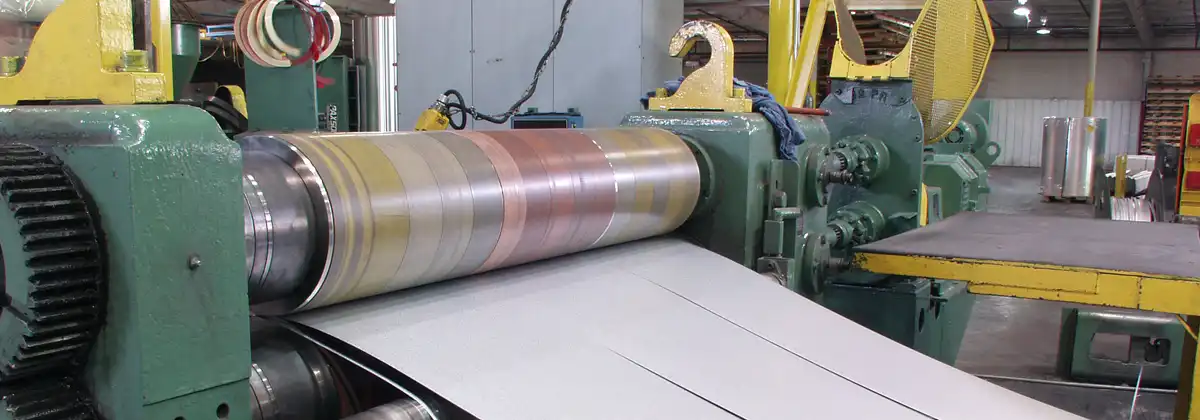

Production process 4-Cutting and slitting

Production process 4-Cutting and slitting Uninterruptible Power Supply (UPS) is...

What are the pre-processing steps for the battery module before and after the capacitance test?

What are the pre-processing steps for the battery module before...

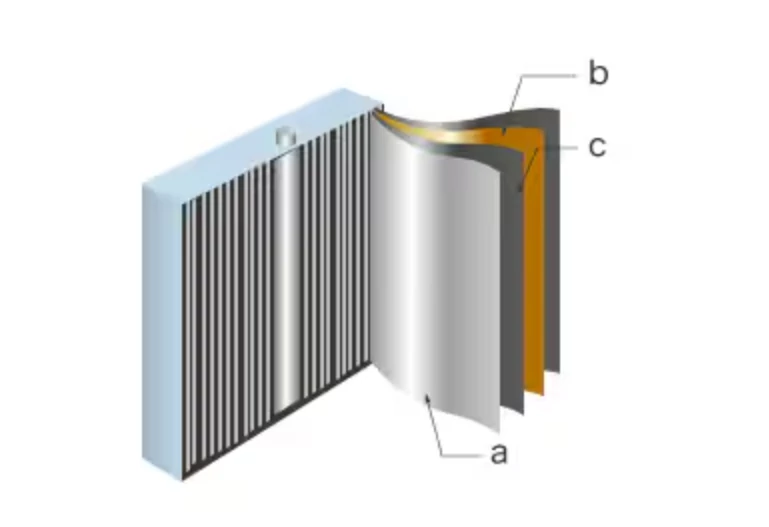

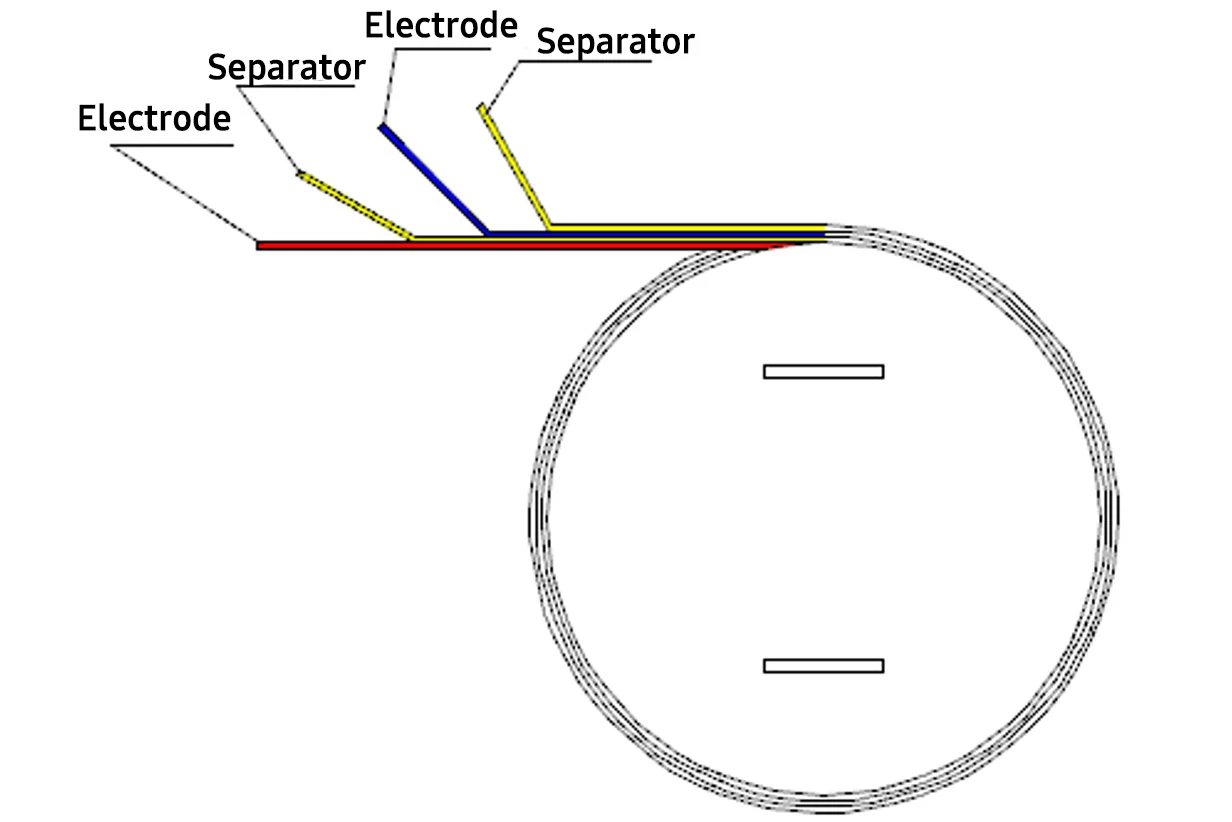

Production process 6-winding

Production process 6-winding In the production process of an Uninterruptible...

The influence of coating surface density on battery capacity

The influence of coating surface density on battery capacity The...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.