Impact of deviation correction accuracy on battery performance The impact...

Production process 4-Cutting and slitting

Uninterruptible Power Supply (UPS) is an indispensable device in modern power guarantee system. The key components of UPS include batteries, inverters, transformers and their distribution systems. In the production process of UPS, cutting and slitter are essential steps, which have a direct impact on the quality and performance of the final product. This article will introduce the UPS production process in detail.

main content

Purpose of cutting and slitting

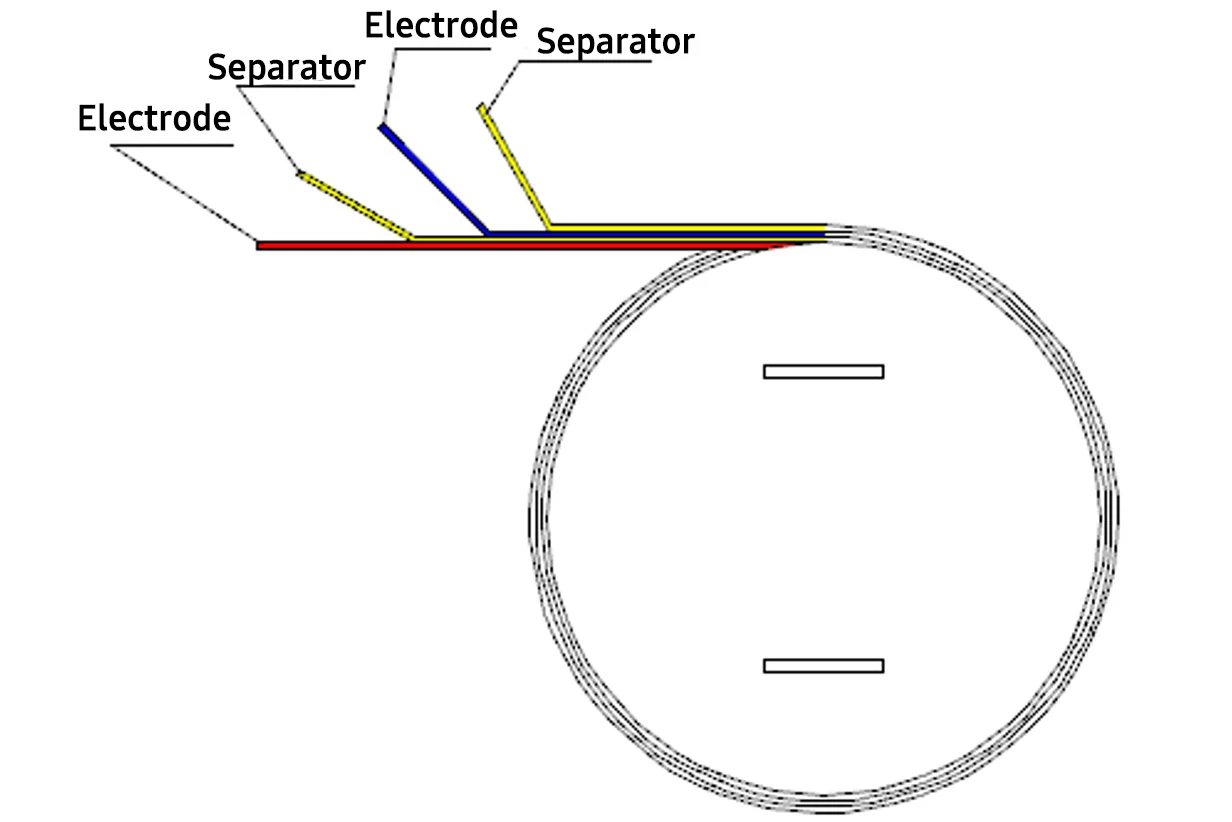

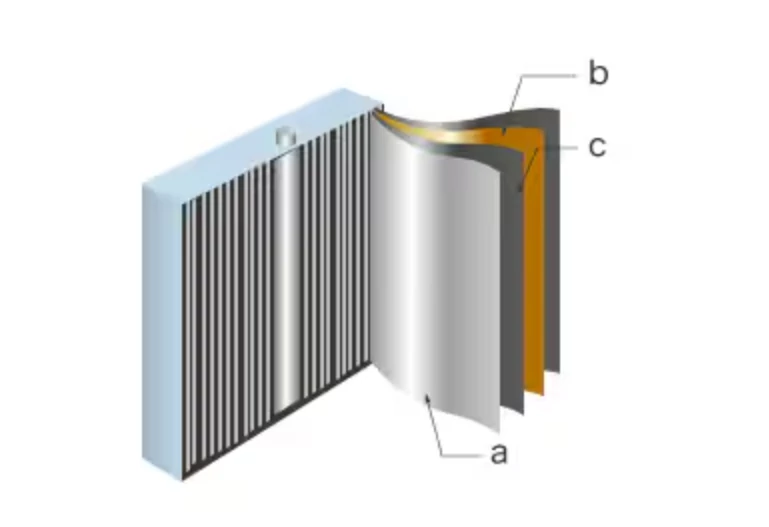

The main purpose of slicing and slitter is to precisely cut the slate-coated, dried and rolled electrode sheet according to the design structure and specifications of the battery. This step is essential to ensure battery performance and quality.

Technical requirements for cutting and slitting:

In the process of cutting, the quality of the cutting edge of the electrode has an important influence on the performance and quality of the battery. The details include:

Burrs and impurities can cause short circuit in the battery, causing self-discharge and even thermal runaway;

The dimensional accuracy is poor, it is impossible to ensure that the negative electrode is completely wrapped in the positive electrode, or the diaphragm completely isolates the positive and negative electrode pieces, causing battery safety problems;

Material thermal damage, coating off, etc., resulting in material loss of activity, can not play a role;

The unevenness of the cutting edge causes the unevenness of the electrode charging and discharging process.

Cutting and slitting process

At present, there are three main cutting processes for lithium-ion batteries:

disk cutting, die punching and laser cutting.

Using the principle of rolling shear, the upper and lower disc knife is used to cut the pole sheet with thickness of 0.01~0.1mm.

Die punching is divided into wood die punching and metal die punching. Metal die punching uses punch and lower die to cut the pole piece. Coating particles are peeled off due to stress during punching, forming punching pieces with high section quality.

Laser cutting has high production efficiency and stability, suitable for lithium-ion battery electrode cutting, the basic principle is to use high power density laser beam to heat the electrode, melt or vaporize the material, form a hole, complete the cutting.

Quality control of cutting and slitting

In the laser cutting process, it is necessary to optimize the process parameters according to the characteristics of the living material and metal foil to ensure that the pole sheet is completely cut, forming a good cutting quality, avoiding problems such as coating shedding and metal chip residue, preventing battery performance degradation and safety quality problems.

Cutting and slitting equipment

The pole cutting equipment needs to have high precision and stability to ensure that the size and quality of the pole plate meet the requirements. These devices include disc cutting machines, die punching machines and laser cutting machines.

CONCLUSION

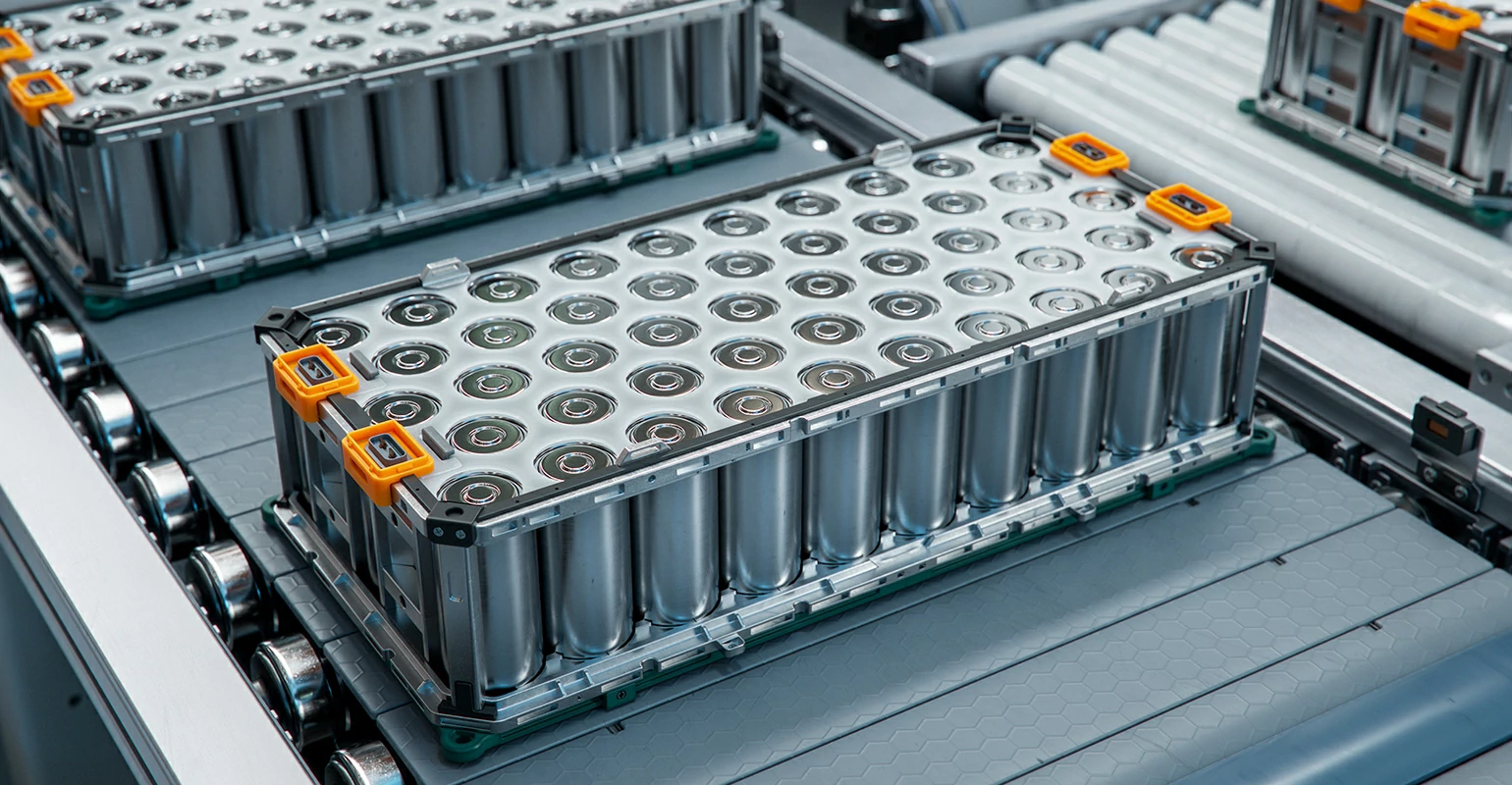

In summary, cutting and slitting is a key link in the UPS battery production process, which directly affects the quality and safety of the battery. By precisely controlling the cutting and slitting process, the quality of the battery electrode can be ensured, thus producing a battery with reliable performance.

UPS BATTERY SERIES

UPS (Uninterruptible Power Supply) batteries are an important component of power supply systems designed to provide stable power support for electronic devices.

Extended reading

Production process 6-winding

Production process 6-winding In the production process of an Uninterruptible...

Production Process 2- Coating

Production Process 2- Coating Uninterruptible Power Supply (UPS) is an...

What are the pre-processing steps for the battery module before and after the capacitance test?

What are the pre-processing steps for the battery module before...

Maintain the battery module after the capacity divider test

Maintain the battery module after the capacity divider test Follow-up...

Production process 10- Formation

Production process 10- Formation In the UPS (uninterruptible power supply)...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.