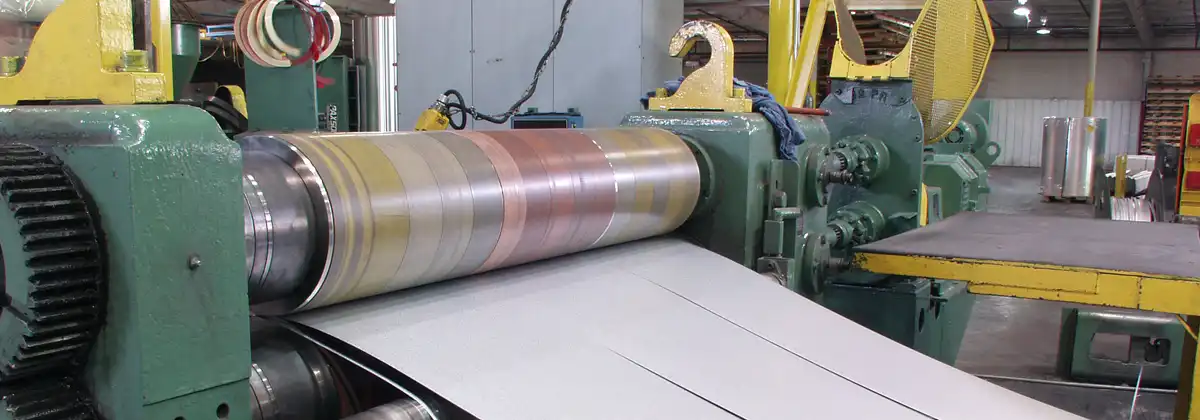

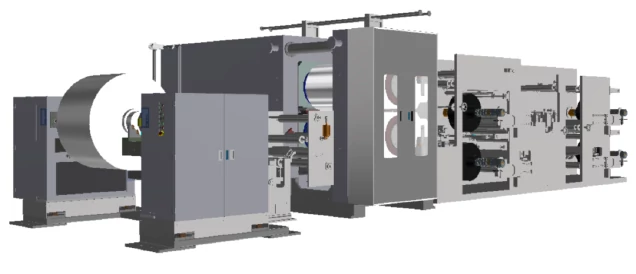

Production process 4-Cutting and slitting Uninterruptible Power Supply (UPS) is...

Impact of deviation correction accuracy on battery performance

The impact of deviation correction accuracy on battery performance is mainly reflected in the following aspects:

Ensure the consistency of the battery pole sheet

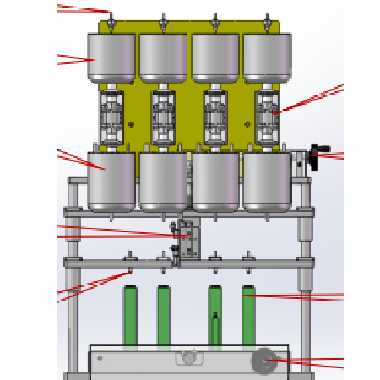

the correction accuracy can ensure the accurate position of the battery pole sheet in the production process and avoid quality problems caused by deviation. The high-precision correction system can ensure that the pole plate runs in accordance with the specified line in the mechanical work, and the correction accuracy can reach 0.1mm, which is crucial to maintain the consistency of the battery pole plate.

Avoid material damage and waste

In the lithium coating and slitting industry, the pole plate may be deviated due to mechanical errors, guide rod deviations, vibrations, and fluctuations in pole tension. This is not only easy to cause pole sheet damage, affect product quality, but also may lead to material waste. The correction system detects the offset of the material through the sensor and responds quickly through the controller to ensure the correct operation of the material, thereby reducing material waste.

Improve battery performance

the correction accuracy directly affects the coating performance of the positive electrode plate of the lithium battery, which in turn affects the performance and quality of the battery. If the accuracy of a coating machine is good, it can achieve good production results through the complete process flow, laying the foundation for the manufacture of higher capacity lithium batteries.

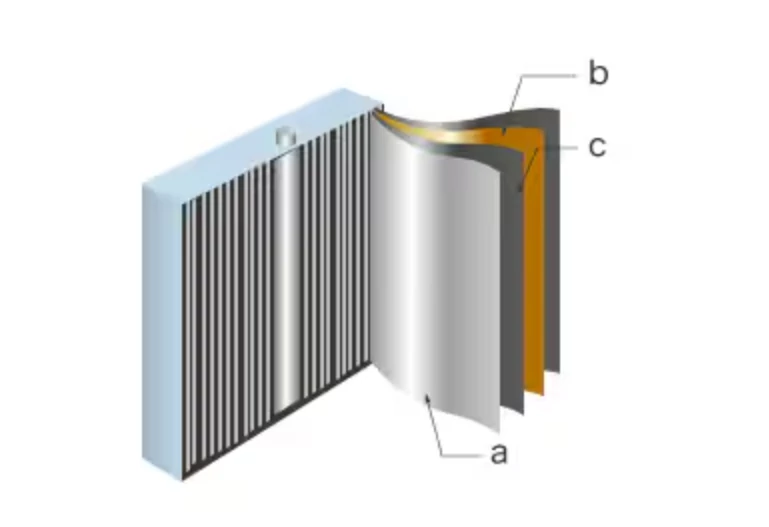

Affect the internal resistance and cycle performance of the battery

Insufficient correction accuracy may lead to inconsistent electrode thickness, which will affect the internal resistance and cycle performance of the battery. The smaller the density of the electrode, the thinner the electrode sheet, the smaller the internal resistance of the battery, the smaller the changes caused to the structure of the electrode sheet when lithium ions are continuously embedded and removed in the charge and discharge cycle, the better the cycle performance, and the higher the capacity retention rate.

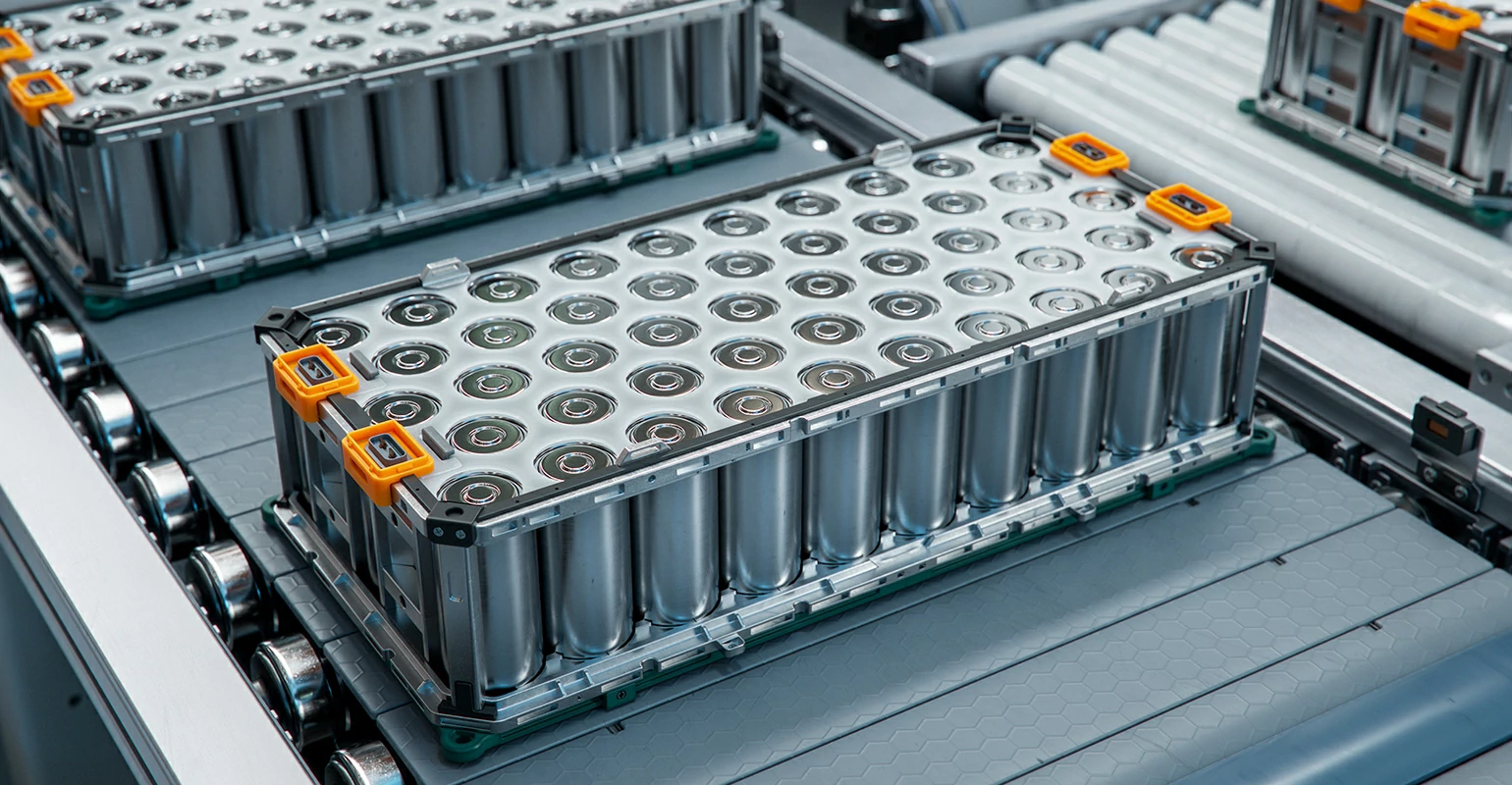

Improve the overall performance of the battery pack

The accuracy of deviation correction is also very important for the battery matching in the battery pack. The match between the cells should be controlled within ± 2.5%, especially in the output of large load current and operating at low temperatures in the battery pack, more stringent battery tolerance control is required. Whether the battery can be well balanced and adapted is related to whether the battery pack has a long service life.

CONCLUSION

In summary, correction accuracy is an important control parameter in the battery manufacturing process, which has a direct impact on the performance, quality and life of the battery. Through high-precision deviation correction control, the overall performance and reliability of battery products can be significantly improved.

UPS BATTERY SERIES

UPS (Uninterruptible Power Supply) batteries are an important component of power supply systems designed to provide stable power support for electronic devices.

Extended reading

Production process 9- liquid injection

Production process 9- liquid injection In the UPS (uninterruptible power...

What are the pre-processing steps for the battery module before and after the capacitance test?

What are the pre-processing steps for the battery module before...

Production process 5- Welding electrode lugs

Production process 5- Welding electrode lugs Uninterruptible Power Supply (UPS)...

Production process 10- Formation

Production process 10- Formation In the UPS (uninterruptible power supply)...

Production process 3- roll pressing

Production process 3- roll pressing Uninterruptible Power Supply (UPS) as...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.