Product testing Product testing is a key link to ensure...

Lamination process

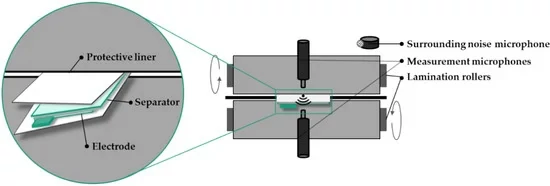

Lamination process is an important process in battery manufacturing, which is mainly used in the production of square batteries. It forms the core structure of the battery by stacking the positive plate, negative plate and diaphragm layer upon layer. This process can ensure the precise alignment and uniform distribution of the various components inside the battery, which is an important part of ensuring battery performance, capacity and consistency.

Lamination process

The lamination process ensures the stability and consistency of the materials inside the battery through accurate lamination and pressing technology, and is one of the core processes of high-capacity and large-size battery production. This process ensures electrochemical performance, cycle stability and safety of the battery, but at the same time requires extremely high precision and process control. Proper pressure control, diaphragm quality, material alignment and lamination speed management are key factors to ensure excellent battery performance.

Concrete process

Align layers

Interlayer alignment is a crucial step in the lamination process, ensuring that the positive, negative and diaphragm are precisely aligned. Any deviation can result in a short circuit, reduced capacity, or erratic performance of the battery.

Accurate interlayer alignment is the key to ensuring battery performance and safety, avoiding battery short circuits and other performance issues.

Pressure control

During the lamination process, the appropriate pressing pressure can ensure tight contact between the electrode and the diaphragm, preventing uneven battery capacity or affecting the battery's conductivity. Proper pressure control ensures a tight battery structure, uniform capacity, and improves battery conductivity and service life.

Quality and selection of diaphragm

The quality of the diaphragm directly affects the safety and performance of the battery, and must have good mechanical strength and porosity, ensure electrical isolation between the electrodes, and support ionic conduction.

High-quality diaphragm can prevent electrode short circuit, improve the safety, stability and performance of the battery.

Lamination speed and consistency

The speed and consistency of lamination affects production efficiency and battery quality. The proper speed ensures the uniformity of the material layer and the consistency of the battery.

Controlling the lamination speed ensures production efficiency while maintaining the consistency and stability of the battery.

low-speed car batteries

Low-speed vehicle battery is a kind of battery designed for low-speed electric vehicles, which has the characteristics of clean, environmental protection, high efficiency and economy, and is widely used in electric golf carts, low-speed electric vehicles (LSV), mobile vendors, campus transportation, cargo trucks and so on

Extended reading

Product packaging and delivery

Product packaging and delivery The packaging and delivery of battery...

Product information expansion

Product information expansion Understanding low-speed vehicle battery product information is...

Product composition

Low-speed lithium battery product composition Understanding the product composition of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.